Reciprocating double moving cutter cutting test device

A test device, reciprocating technology, applied in the field of machinery, can solve the problems of complicated changing test parameters, inconvenient research, crop harvesting season restrictions, etc., and achieve the effect of reducing the probability of failure, simplifying the installation and debugging process, and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

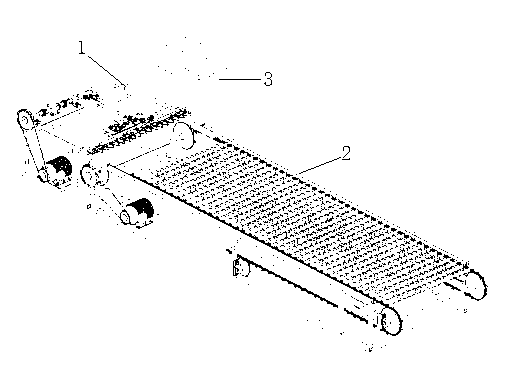

[0023] Overall structure of the present invention sees figure 1 , the cutting mechanism 1 is docked with the stalk feeding mechanism 2, the upper blade 116 and the lower blade 120 are located above the transmission wheel 203, and the stalk feeding mechanism 2 is fed to the cutting edge of the cutting mechanism 1 to be cut.

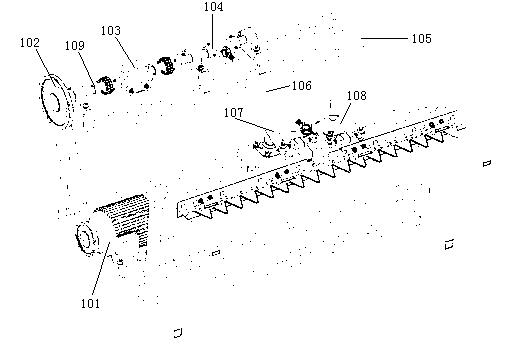

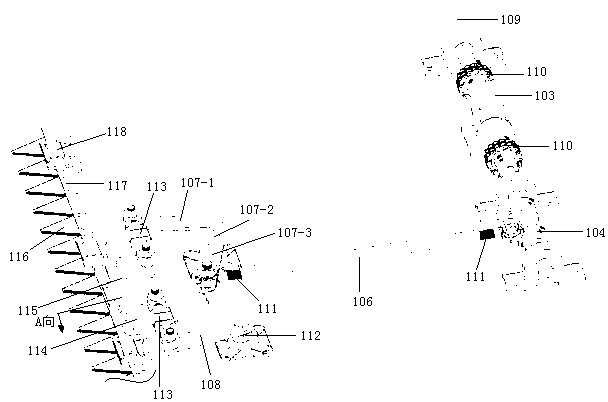

[0024] The concrete structure of cutting mechanism of the present invention sees figure 2 and image 3 , the motor 101 and the belt drive 102 are installed on the outside of the cutting frame 105, the motor 101 drives the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com