Automatic dispatch method

An automatic dispatching and tooling technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of low efficiency and repeated conveying times, and achieve the goal of reducing invalid conveying, preventing machine from being idle, and improving conveying efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and drawings therein are illustrative in nature and not limiting. this invention.

[0021] The automatic dispatching method of the preferred embodiment of the present invention will be specifically introduced below.

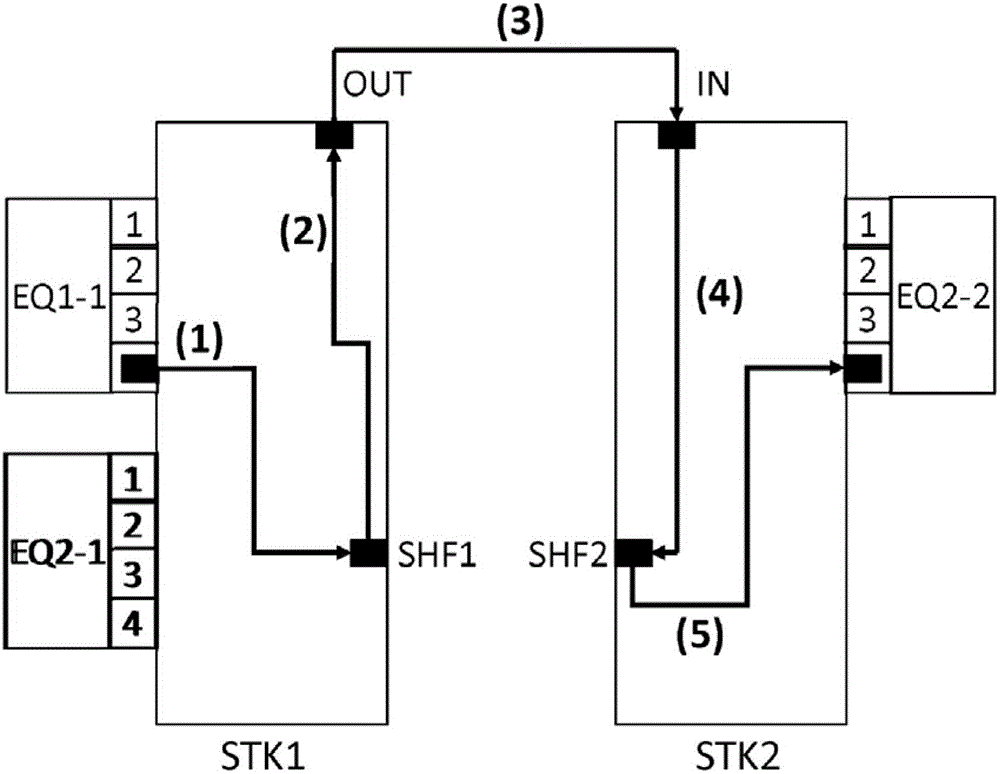

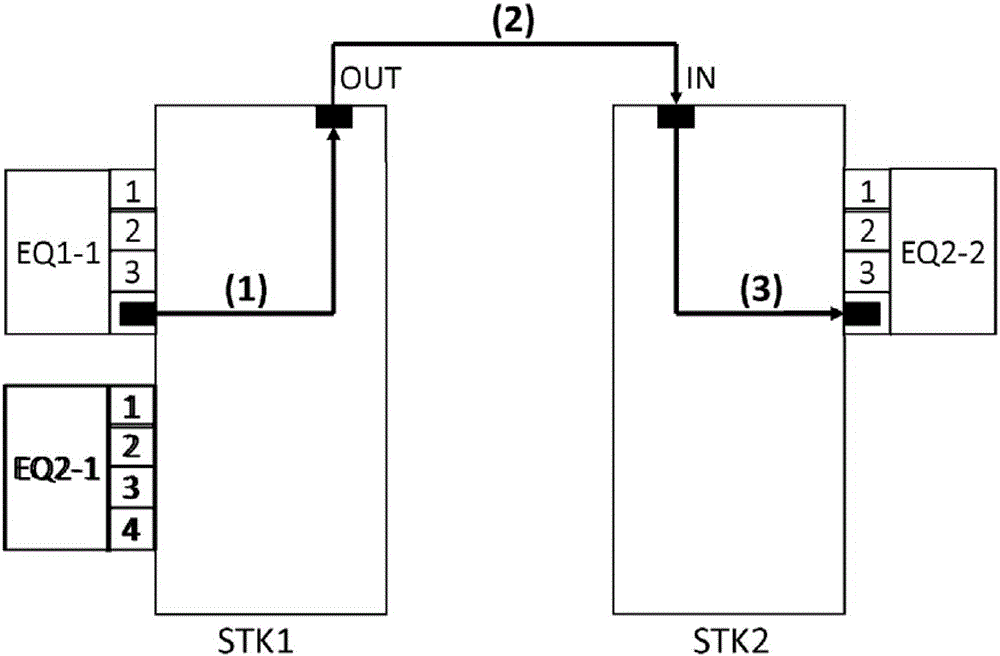

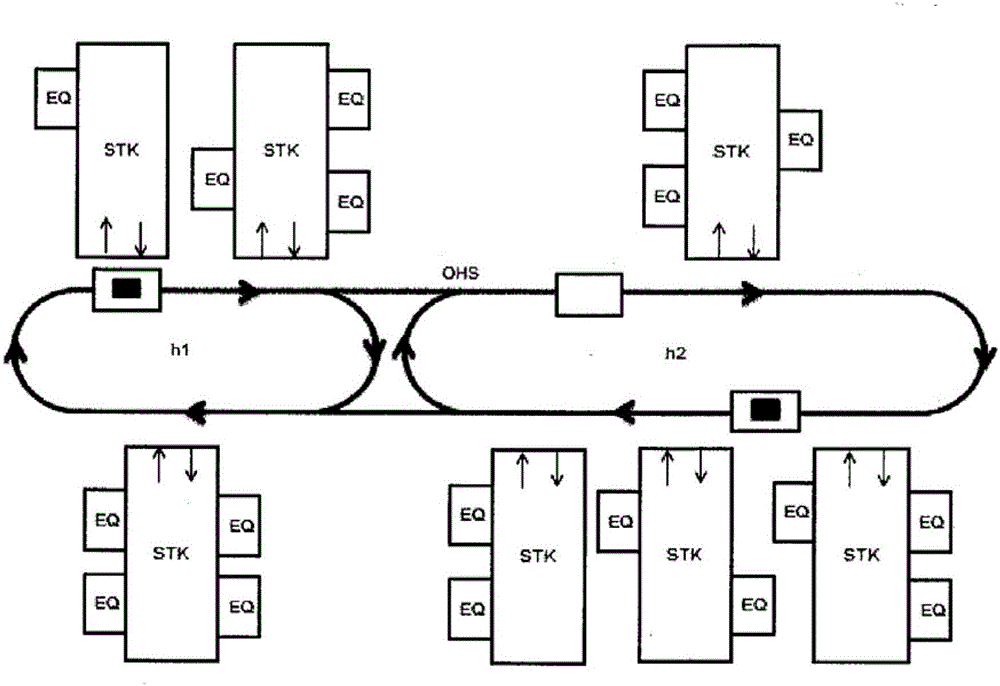

[0022] The automatic dispatching method of the embodiment of the present invention is used for material transportation between the source storage unit and the destination storage unit in the manufacturing process of electronic components. The electronic component is preferably a display panel. The automatic dispatching method of the embodiment of the present invention , including three steps, namely, the transfer step within the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com