Textile wastewater treatment method and device

A technology of textile wastewater and treatment device, which is applied in textile industry wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Guarantee the effect of stable compliance and high MBR membrane flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

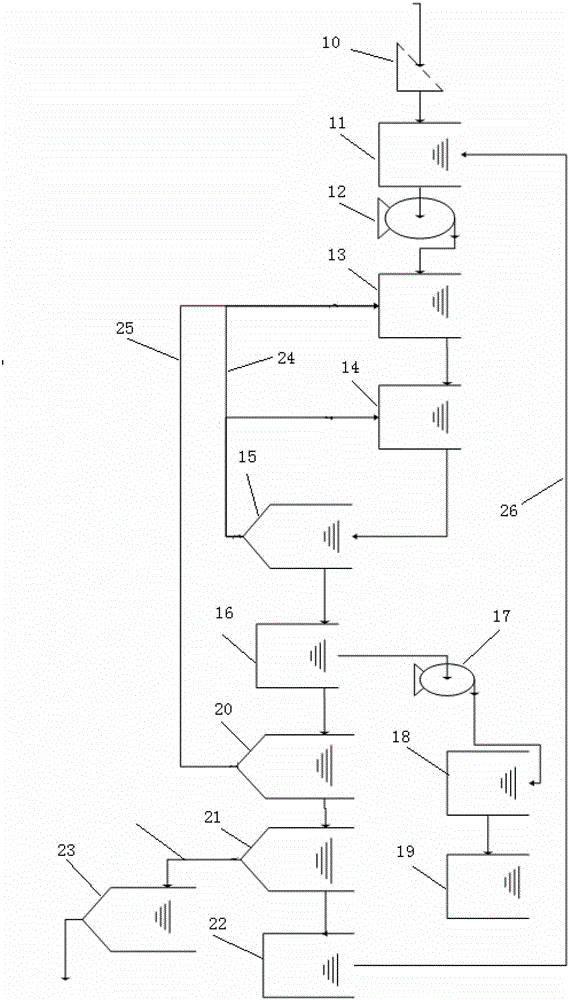

[0024] Such as figure 1 As shown, the textile wastewater treatment device of the present invention mainly includes an A / O biochemical treatment unit, an MBR membrane treatment unit and an MBR membrane dope advanced treatment unit. In the present invention, there are biochemically undegradable substances in the high-concentration textile wastewater treated by MBR, and this part of the wastewater is called MBR membrane dope.

[0025] The A / O biochemical treatment unit includes a regulating tank 11, an anaerobic tank 13, an activated sludge tank 14, and a biochemical sedimentation tank 15 connected in sequence; The bottom of the anaerobic tank 13 and the activated sludge tank 14 are connected, wherein the biochemical sludge return pipe 24 returns to the pulse tank of the anaerobic tank 13 . A grid machine 10 is installed in front of the regulating tank 11, and the width of the grid is set to 1mm, the purpose is to prevent the residual fibers and suspended matter in the textile w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com