Aeration and low frequency ultrasonic wave reinforced film coagulation reaction separating device and method for producing drinking water thereby

A separation device, ultrasonic technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sewage multi-stage treatment, etc. The filtration process occupies a large area and other problems, so as to achieve the effect of flexible scale, prolonging the backwash cycle, and reducing irreversible membrane fouling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

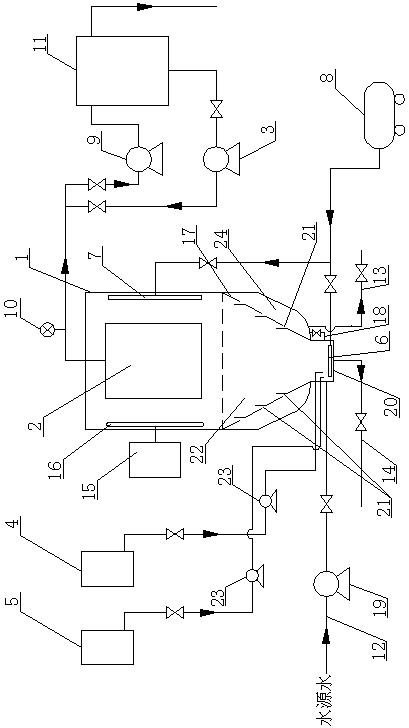

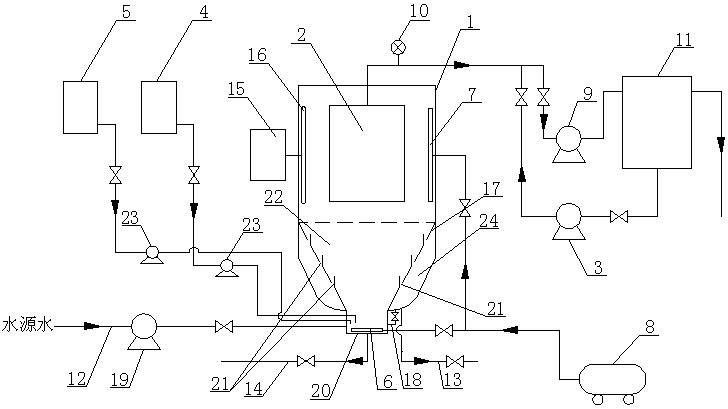

[0008] Specific implementation mode one: combine figure 1 To illustrate, in this embodiment, aeration and low-frequency ultrasonic waves are used to strengthen the membrane coagulation reaction separation device, which includes a housing 1, an ultrafiltration membrane module 2, a backwash pump 3, a coagulant dosing tank 4, and a first aerator 6. Second aerator 7, blower 8, suction pump 9, pressure sensor 10, clean water tank 11, water inlet pipe 12, mud discharge pipe 13, backwash mud discharge pipe 14, ultrasonic generator 15, ultrasonic metal plate 16. Conical mud discharge plate 17, lift pump 19 and groove 20. The bottom of the housing 1 is provided with a groove 20. The bottom of the groove 20 is equipped with a first aerator 6 and a coagulant dosing tank 4. The liquid outlet of the water inlet is connected with the liquid inlet on the side wall of the groove 20, the water outlet of the water inlet pipe 12 is connected with the water inlet on the side wall of the groove 20...

specific Embodiment approach 2

[0011] Embodiment 2: This embodiment is different from Embodiment 1 in that: the material of the housing 1 is plexiglass or stainless steel. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0012] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the material of the ultrafiltration membrane module 2 is an organic membrane module, a ceramic membrane module or a stainless steel membrane module. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com