A method for preparing silicon by molten salt electrolysis

A molten salt electrolysis and molten salt technology, applied in the electrolysis process, electrolysis components, silicon and other directions, can solve the problems of large pollution, low production efficiency and high energy consumption, achieve a wide range of operating temperatures, and facilitate continuous electrolysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

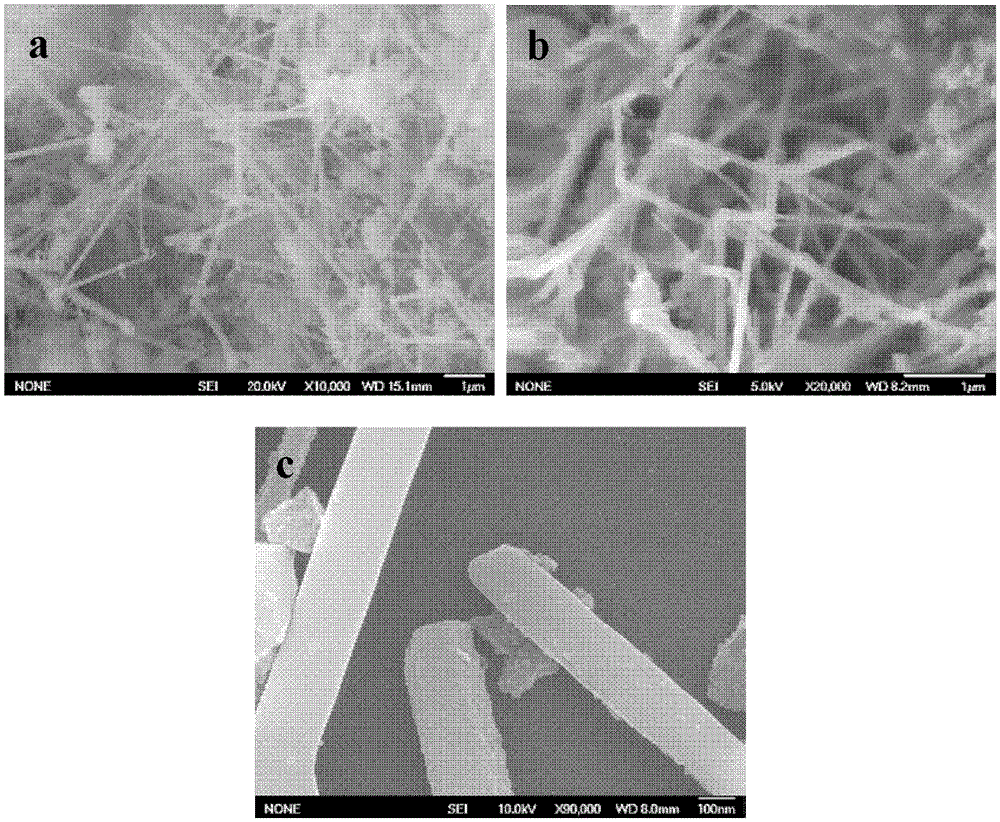

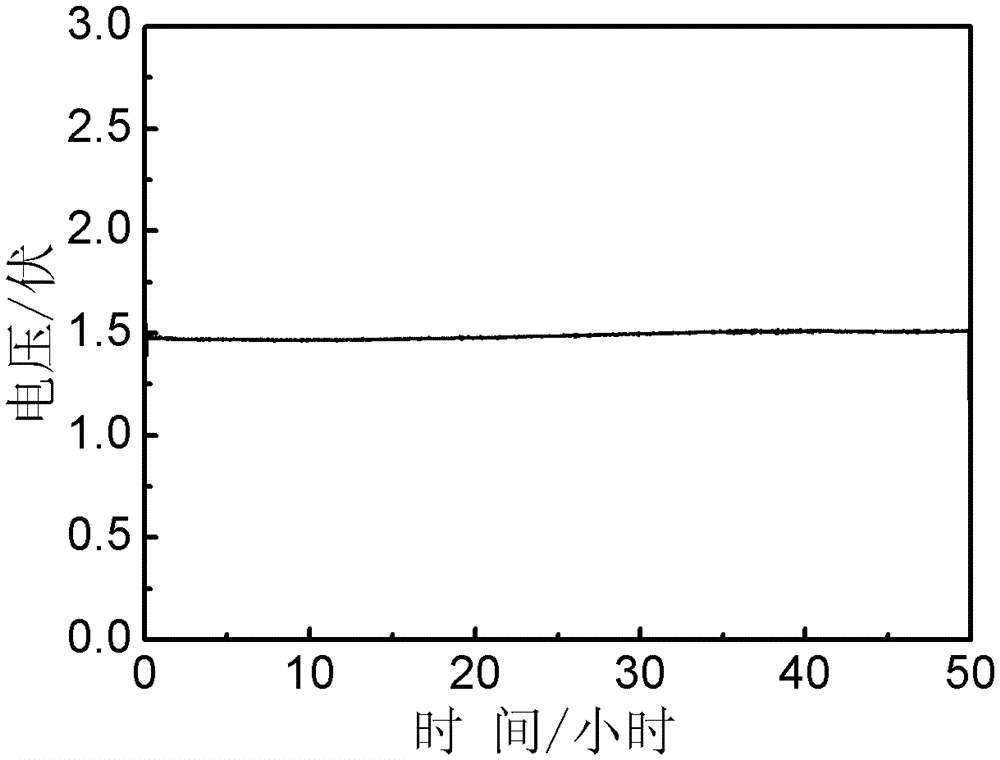

[0032] A method for preparing silicon by molten salt electrolysis, characterized in that the composition of the molten salt system is (55%) KF (42%) AlF 3 (3%)SiO 2 ; The electrolysis temperature is 720℃; carbon is the cathode and anode, the pole distance is 2cm; the electrolysis current density is controlled at 0.5A / cm 2 . The cell voltage in the electrolysis process is stable at 1.4V, according to the SiO in the molten salt 2 Replenish SiO in time 2 , SiO 2 Dissolve quickly. A silicon wire with a purity of 98.9 wt% is obtained by electrolysis, the silicon wire has a morphological diameter of 150 nm, a length of 3-10 μm, and contains 1 wt% of linear micron silicon carbide. The SEM image of the silicon obtained by electrolysis in Example 1 is as figure 1 Shown, where, figure 1 A: ×10000 times; figure 1 B: ×20000 times; figure 1 C: ×90000 times. The cell voltage change in the silicon electrolysis process in Example 1 is as follows figure 2 Shown.

Embodiment 2

[0034] A method for preparing silicon by molten salt electrolysis, characterized in that the composition of the molten salt system is (55%) NaF (42%) AlF 3 (3%)SiO 2 ; The electrolysis temperature is 750℃; carbon is the cathode, alloy is the inert anode, the pole distance is 2cm; the electrolysis current density is controlled at 0.2A / cm 2 . During the electrolysis process, the cell voltage was stable at 1.4V, and silicon nanowires and silicon nanofibers were obtained by electrolysis, with a purity of 99.2% by weight.

Embodiment 3

[0036] A method for preparing silicon by molten salt electrolysis, characterized in that the composition of the molten salt system is (60%) KF (38%) AlF 3 (2%)SiO 2 ; The electrolysis temperature is 800℃; carbon is the cathode and anode, the pole distance is 2cm; the electrolysis current density is controlled at 0.5A / cm 2 . During the electrolysis process, the cell voltage was stable at 1.4V, and nano silicon particles were obtained by electrolysis, with a purity of 99.8 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com