Track maintenance base point plane measurement method

A plane measurement and orbit technology, applied in the field of surveying and mapping, can solve the problems of manpower waste, increase working time, reduce work efficiency, etc., and achieve the effect of improving observation efficiency, shortening observation time, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] Embodiment: The observation method of this embodiment is used to provide an observation network type, which can save manpower by observing the base points of orbit maintenance together in the process of repeating the plane observation at the CPⅢ point (that is, the orbit control network point). And improve the observation efficiency.

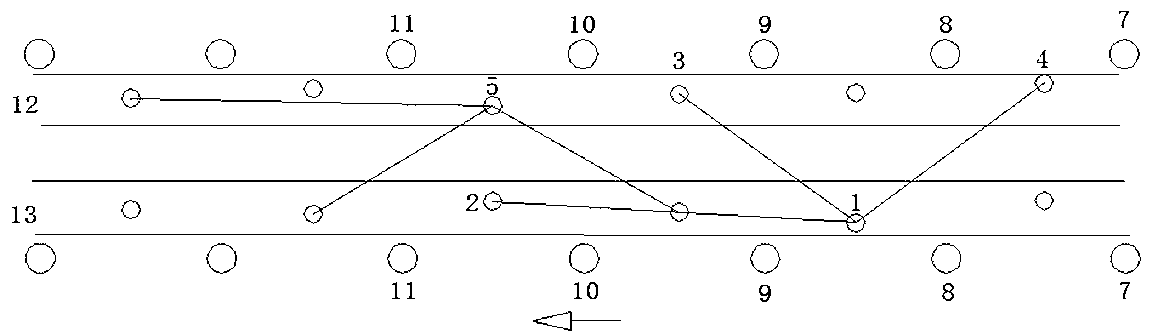

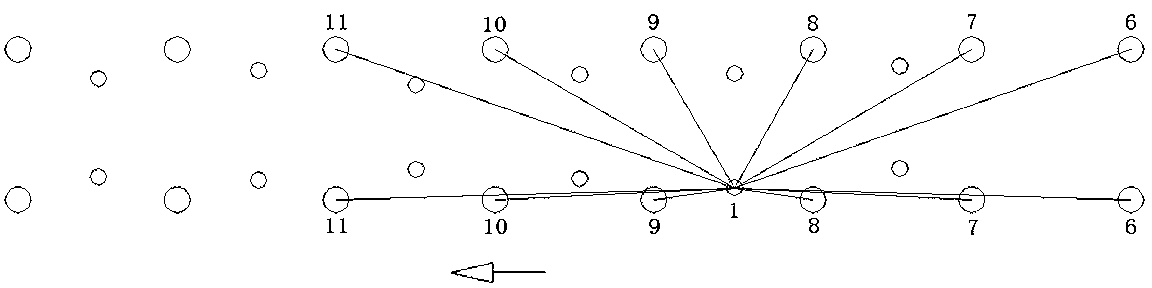

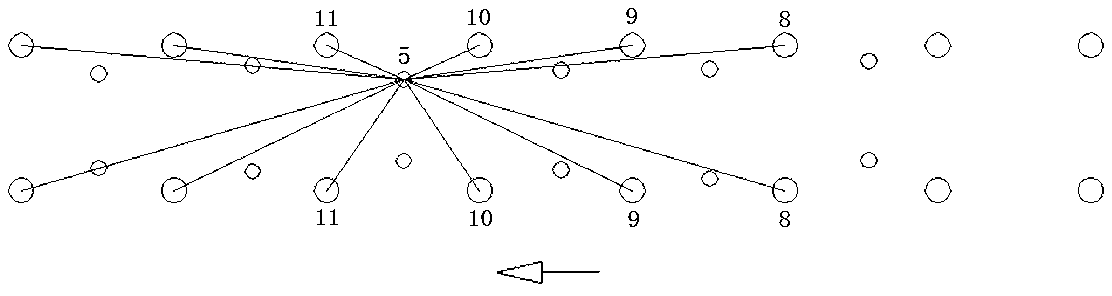

[0019] Such as figure 1 As shown in , the direction indicated by the arrow is the direction of observation along the track, that is, the track maintenance base point and CPⅢ point are observed sequentially along the direction of observation of the track. The first station 1, the track maintenance base point 2, the track maintenance base point 3, the track maintenance base point 4, and the second station 5 are respectively located on track 12 or track 13; figure 1 , 2 As shown, CPⅢ point 6, CPⅢ point 7, CPⅢ point 8, CPⅢ point 9, CPⅢ point 10, and CPⅢ point 11 are all track control network points, and refer to a pair on both sides of trac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com