Underground coal mine dust collecting device

A dust removal device and coal mine technology, applied in safety devices, dust prevention, mining equipment, etc., can solve problems such as high working pressure, high cost of use, easy to damage coal quality, etc., to reduce water consumption, facilitate interception, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

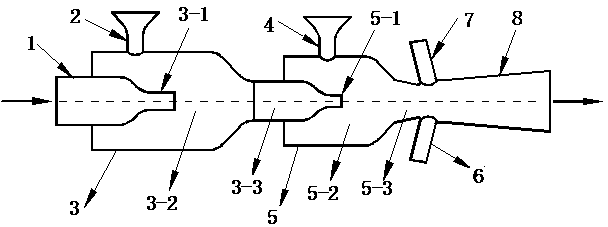

[0015] Embodiment 1: Coal mine underground dust removal device includes: compressed air inlet 1, first dust suction inlet 2, primary ejector 3, first inner nozzle 3-1, first receiving chamber 3-2, first mixing chamber 3 -3, the second dust suction inlet 4, the secondary ejector 5, the second inner nozzle 5-1, the second receiving chamber 5-2, the second mixing chamber 5-3, the water inlet 6, the dust removal agent inlet 7 and Nozzle 8; one end of the compressed air inlet 1 is the inlet of the wind, and the other end is the first inner nozzle 3-1, the compressed air inlet 1 is inserted into the primary ejector 3, and there is a first Dust suction port 2, the first dust suction port 2 is located at the position of the first receiving chamber 3-2; the primary ejector 3 has the first receiving chamber 3-2, and there is a first receiving chamber 3-2 at the front end of the first receiving chamber 3-2. Mixing chamber 3-3, the end of the first mixing chamber 3-3 is the second inner n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com