Pneumatic tyre tread comprising a plurality of incisions

A tire tread, sipe technology, applied in tire tread/tread pattern, tire parts, transportation and packaging, etc., can solve problems such as energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In the following description, the same reference numerals will indicate the same or similar elements.

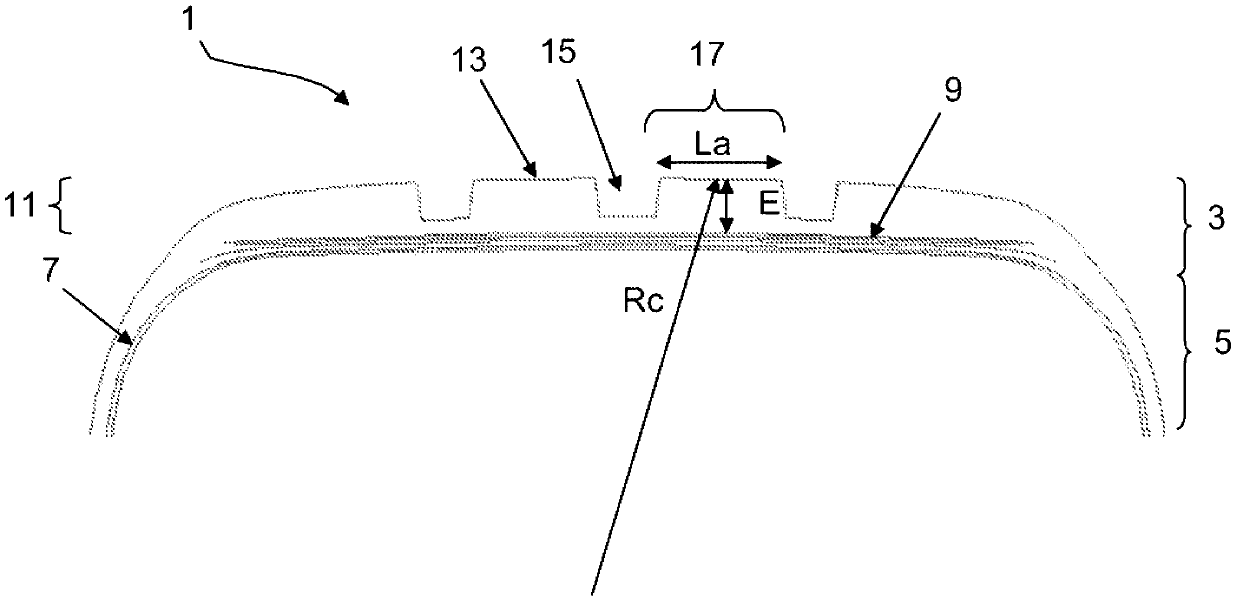

[0061] figure 1 A partial sectional view of the tire 1 is schematically depicted.

[0062] The tire 1 comprises a crown comprising a crown region 3 extending laterally by a sidewall 5 connected to a bead (not shown) intended to come into contact with a mounting rim.

[0063] The tire 1 comprises a carcass reinforcement 7 extending from one bead to the other via the sidewalls 5 and the crown region 3 .

[0064] The crown region 3 comprises a reinforcement 9 covered radially on the outside by a tread 11 .

[0065] The tread 11 includes, on the radially outer side, a tread surface 13 intended to contact the ground when the vehicle is running.

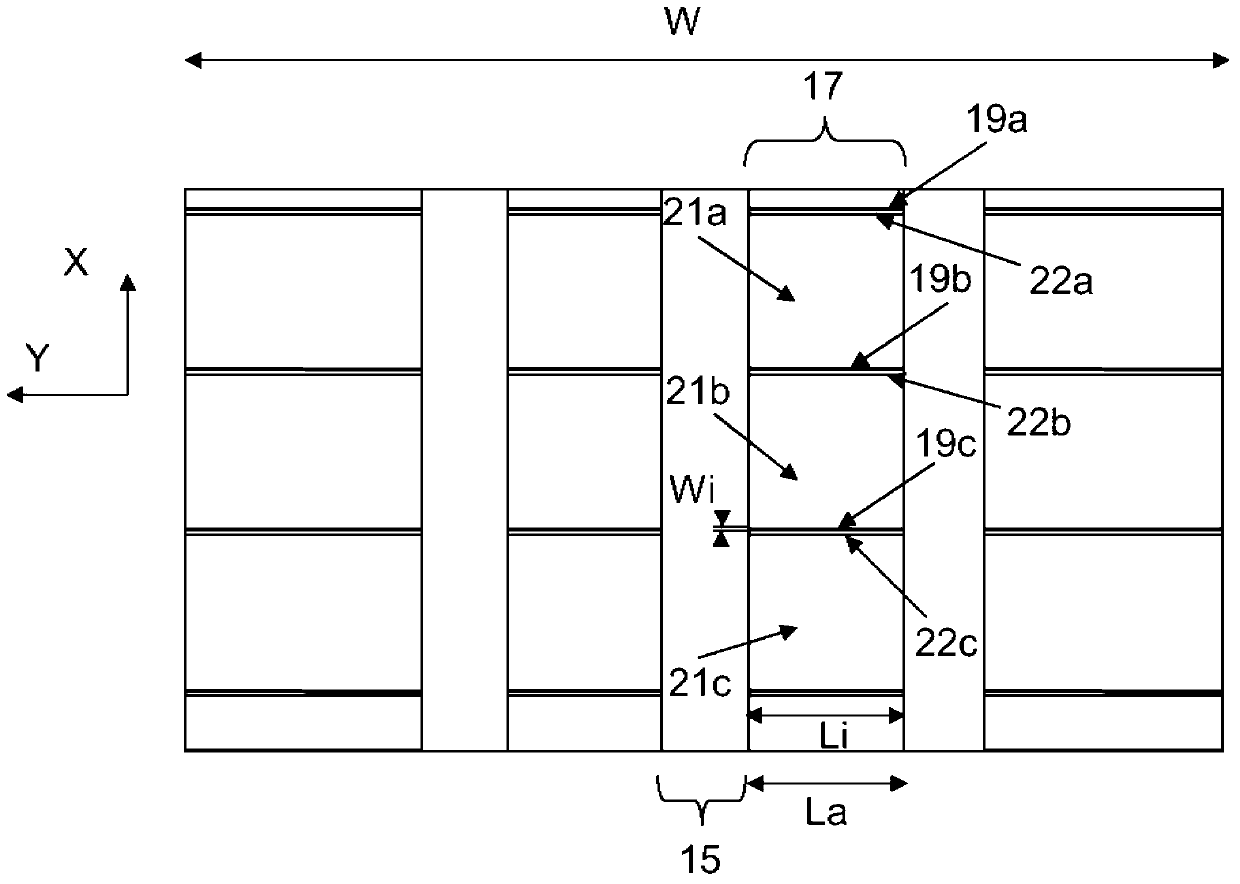

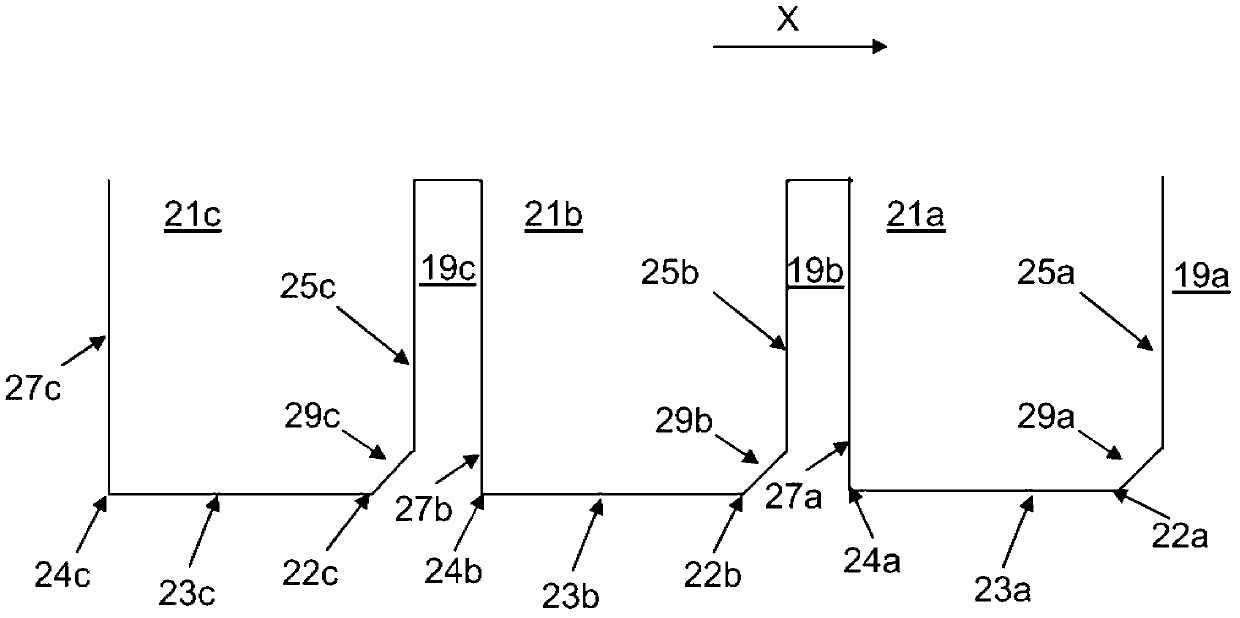

[0066] The tread 11 includes a plurality of grooves 15 .

[0067] The grooves 15 delimit a raised circumferential band 17 .

[0068] Each circumferential band 17 has a contact surface intended to contact the ground when the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com