Motor vehicle lock with low-noise lock bow

A technology for motor vehicles, lock bows, applied in anti-noise/anti-rat locks, vehicle locks, building locks, etc., to minimize the pressure load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

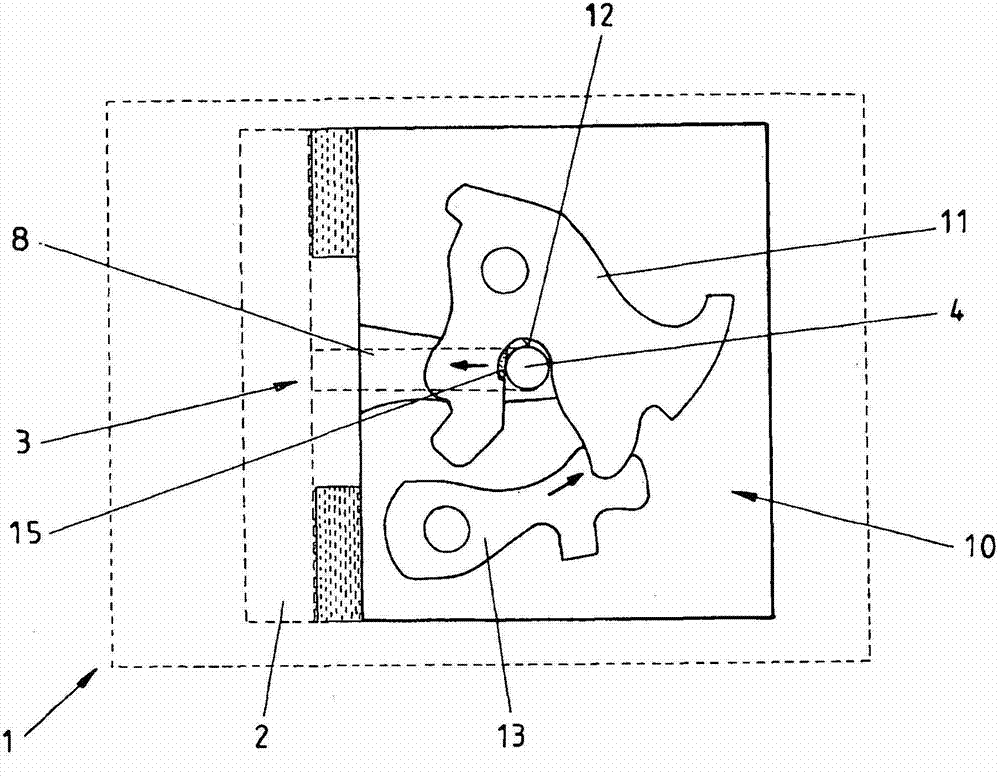

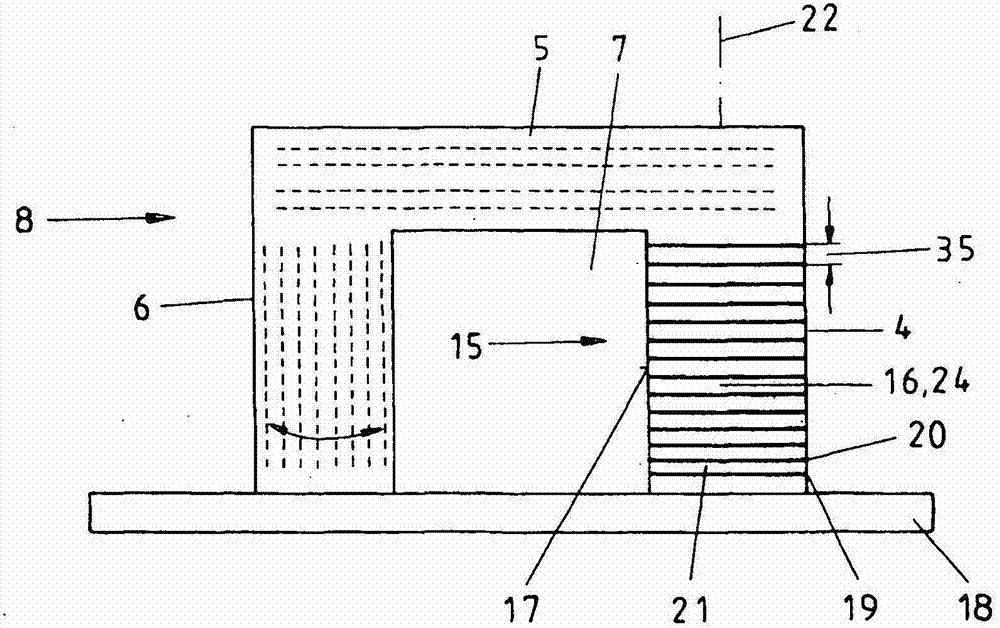

[0028] figure 1 A motor vehicle lock 1 is shown, which is installed in a motor vehicle body 2 . The lock bracket 3 and the lock bow 8 can be seen, which has the two bow legs 4 , 6 and the bow bridge 5 and the recess 7 formed therebetween. figure 2 The corresponding content is shown more clearly.

[0029] In addition to the lock bracket 3 , a locking mechanism 10 is shown which comprises, inter alia, a door latch 11 with a receptacle 12 and a pawl 13 . In the example shown, the pawl 13 has been inserted so that the door latch 11 cannot be moved out of the position shown. In this position, loads can be caused by the different movements of the two parts, lock bracket 3 and locking mechanism 10 , so that corresponding loads and especially unpleasant noises can occur in contact area 15 .

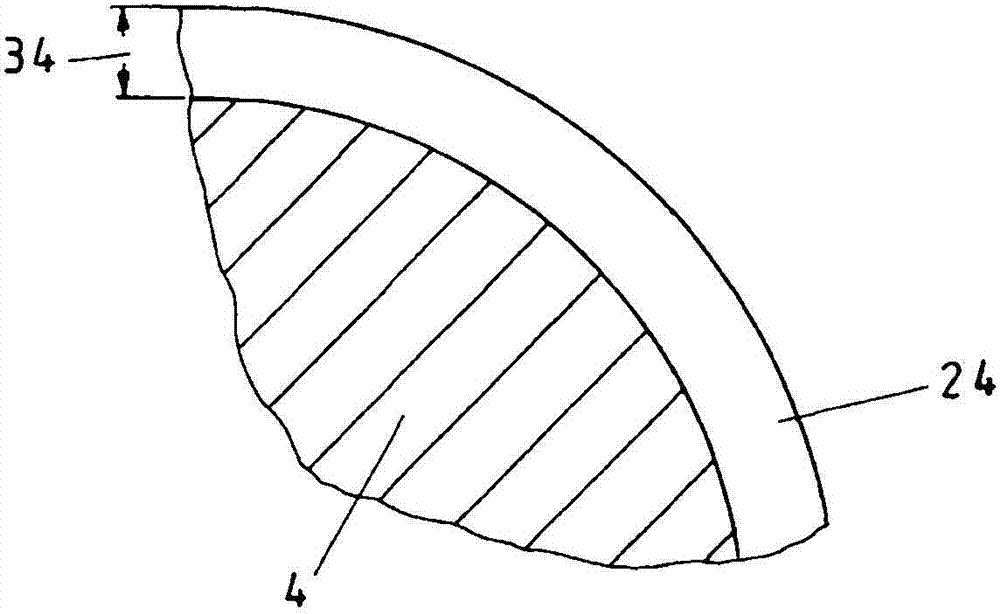

[0030] figure 2 It is shown that the contact region 15 has a special configuration or machining in order to create a special surface structure 16 . The entire outer wall 17 of the loaded bow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com