Ceramic tile automatic packaging production line

An automatic packaging and production line technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve problems such as harsh working environment, long process, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

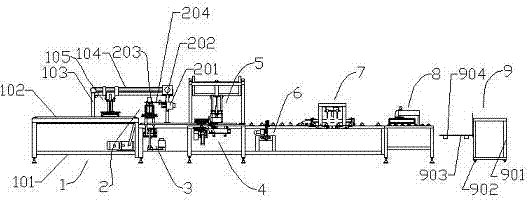

[0093] Example 1, such as figure 1 As shown, the tile automatic packaging production line includes a tile stacking device 1, and the tile stacking device 1 includes a first frame 101, and the first frame 101 is provided with a first bracket 103, and the first bracket 103 There is a paper holding device 2 on the top, the lower part of the paper holding device 2 is provided with a grading device 3, one side of the grading device 3 is provided with a rotating device 4, and the upper part of the rotating device 4 is provided with a brick moving device 5. The side of the rotating device 4 far away from the upgrading device 3 is provided with a gluing device 6, and the side of the gluing device 6 far away from the rotating device 4 is provided with a tongue folding device 7, and the tongue folding device 7 is far away from the applicator. A sealing device 8 is provided on one side of the gluing device 6 , and a palletizing device 9 is provided on a side of the sealing device 8 away...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com