Combined type rolling guide shoe

A rolling guide shoe, combined technology, applied in the direction of elevators, transportation and packaging, etc., can solve the problems of increased maintenance costs, only front and rear adjustment, increased local pressure friction, etc., to achieve easy disassembly and assembly transportation, and improve comfort Stability, the effect of reducing storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

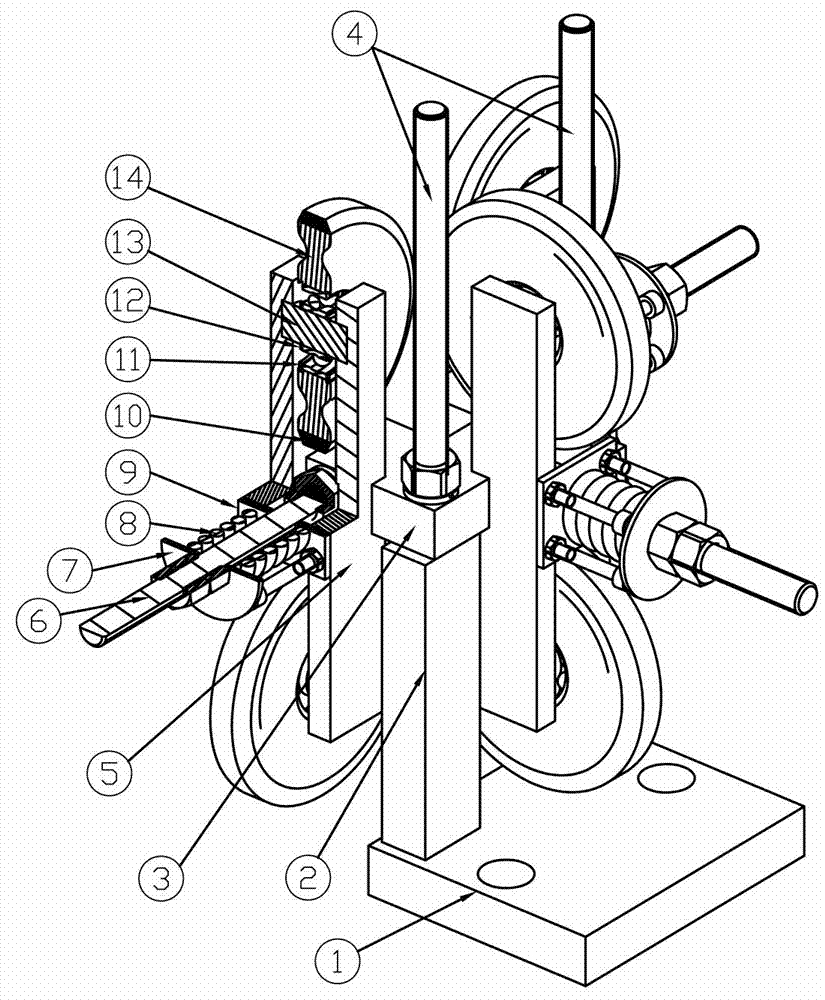

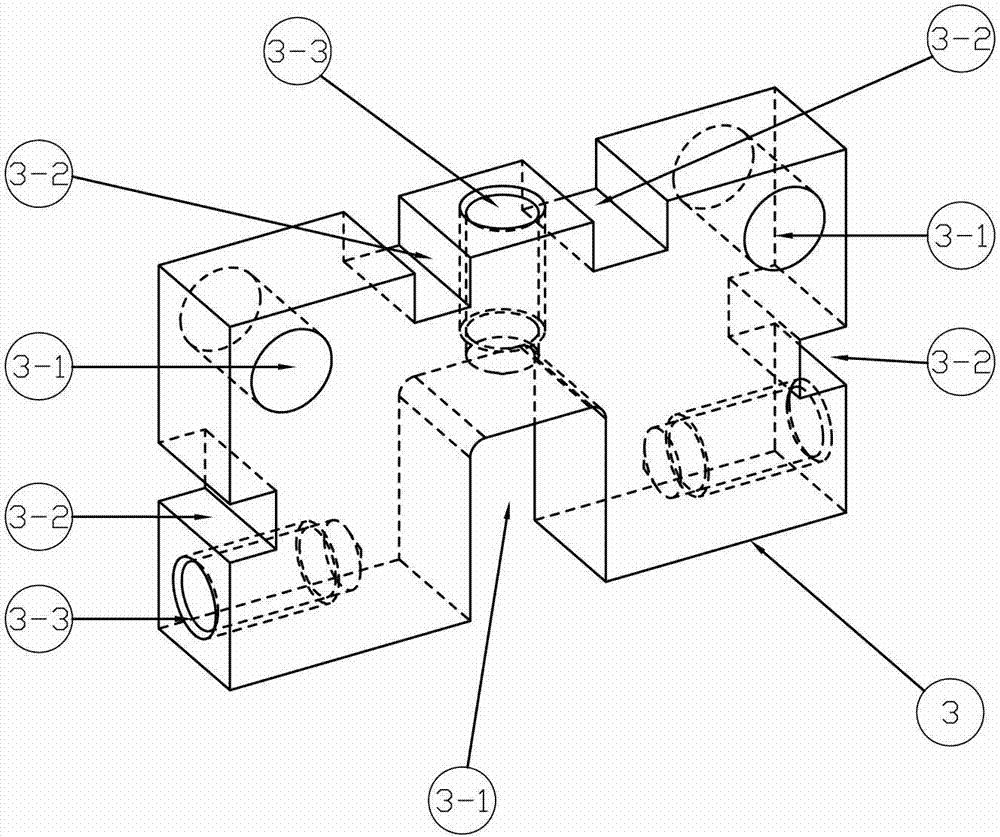

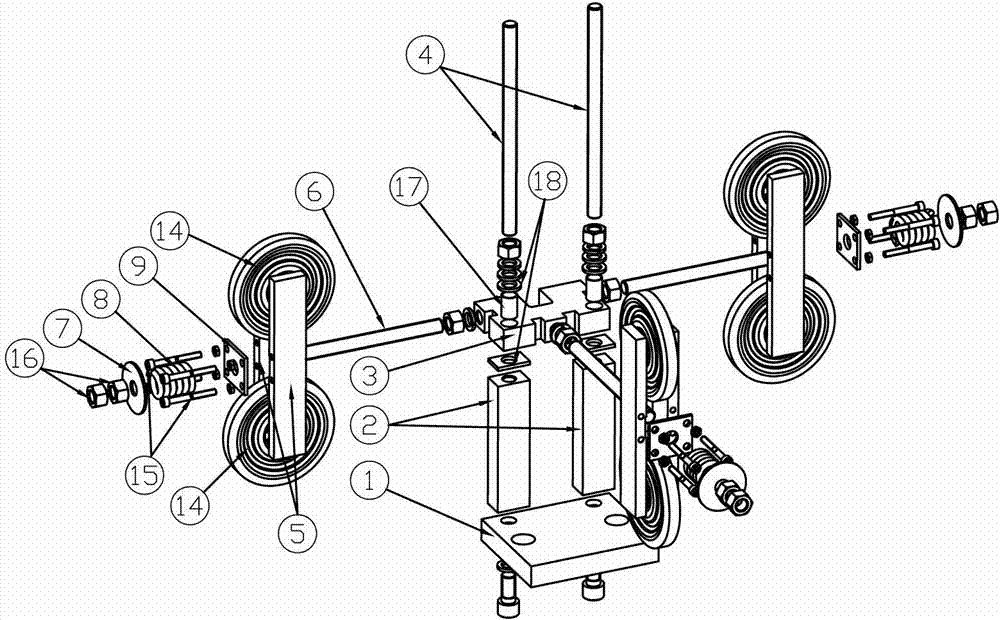

[0011] Embodiments of the present invention are described below with reference to the accompanying drawings, as figure 1 As shown, the present invention is mainly composed of a guide shoe base frame, a roller mechanism and a shock-absorbing component, and it also includes a card position connecting plate 3 and three card position stoppers 5 that are locked with the card position connecting plate 3; the guide shoe The base frame includes: a base plate 1 and two supporting columns 2; the roller mechanism is composed of a roller 14, a roller bearing 12, a circlip 11 and a roller shaft 13, wherein the outer surface of the roller 14 is a layer of polyurethane wheel Surface 10. Usually, the top and the bottom of the elevator car are connected with at least one pair of rolling guide shoes, which are respectively used to cooperate with the guide rails on both sides of the elevator, and each rolling guide shoe is generally provided with three roller mechanisms, and the three roller mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com