Organosilicon macromolecular composite waterproof gypsum and preparation method thereof

A technology of silicon polymer and water-soluble polymer, applied in the field of gypsum, can solve the problems of complex preparation process and long storage time of silicone resin emulsion, and achieve the effect of simple preparation process, excellent long-term waterproof performance and excellent waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

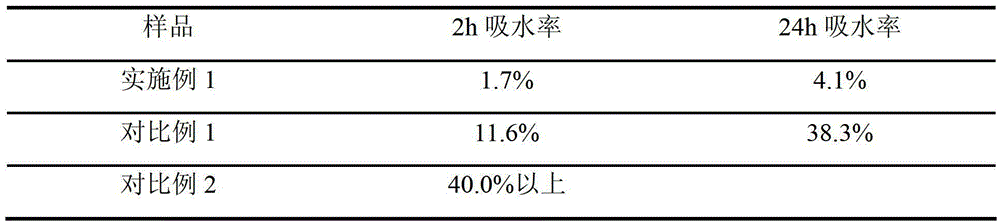

Examples

Embodiment 1

[0030] The raw materials are weighed according to the following composition, and the waterproof gypsum product of the present invention is prepared:

[0031] Desulfurized building gypsum: 100g

[0032] Silane coupling agent A151: 1.0g

[0033] Acetic acid: 0.5g

[0034] Water-soluble starch: 0.7g

[0035] Water: 80g

[0036] The preparation method is as follows:

[0037] Dissolve 0.7g of water-soluble starch in water at 95-100°C to make a starch aqueous solution with a mass fraction of 10%, which is component A; dissolve 0.5g of acetic acid in 50g of water, add 1.0g of silane coupling Agent A151, keep stirring until the solution is clear, it is component B; mix component A, component B and the remaining water, put in 100g of construction gypsum, mix well, stir for 2min, pour into the mold, scrape off the remaining material on the surface, After the gypsum is solidified, it is demolded and dried to obtain the finished product.

Embodiment 2

[0062] Similar to Example 1, the difference is that the silane coupling agent A151 is 0.1 g, the acetic acid is 1 g, and the water-soluble cellulose is 1 g.

Embodiment 3

[0064] Similar to Example 1, the difference is that the silane coupling agent A151 is 2 g, the hydrochloric acid is 0.1 g, and the water-soluble starch is 0.1 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com