Maltol separation and purification method

A purification method and maltol technology, applied in the field of maltol separation and purification, can solve the problems of maltol decomposition, difficult separation, low product yield, and high sublimation temperature, and achieves reduction of by-product waste asphalt, high separation efficiency, and high operation efficiency. low temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

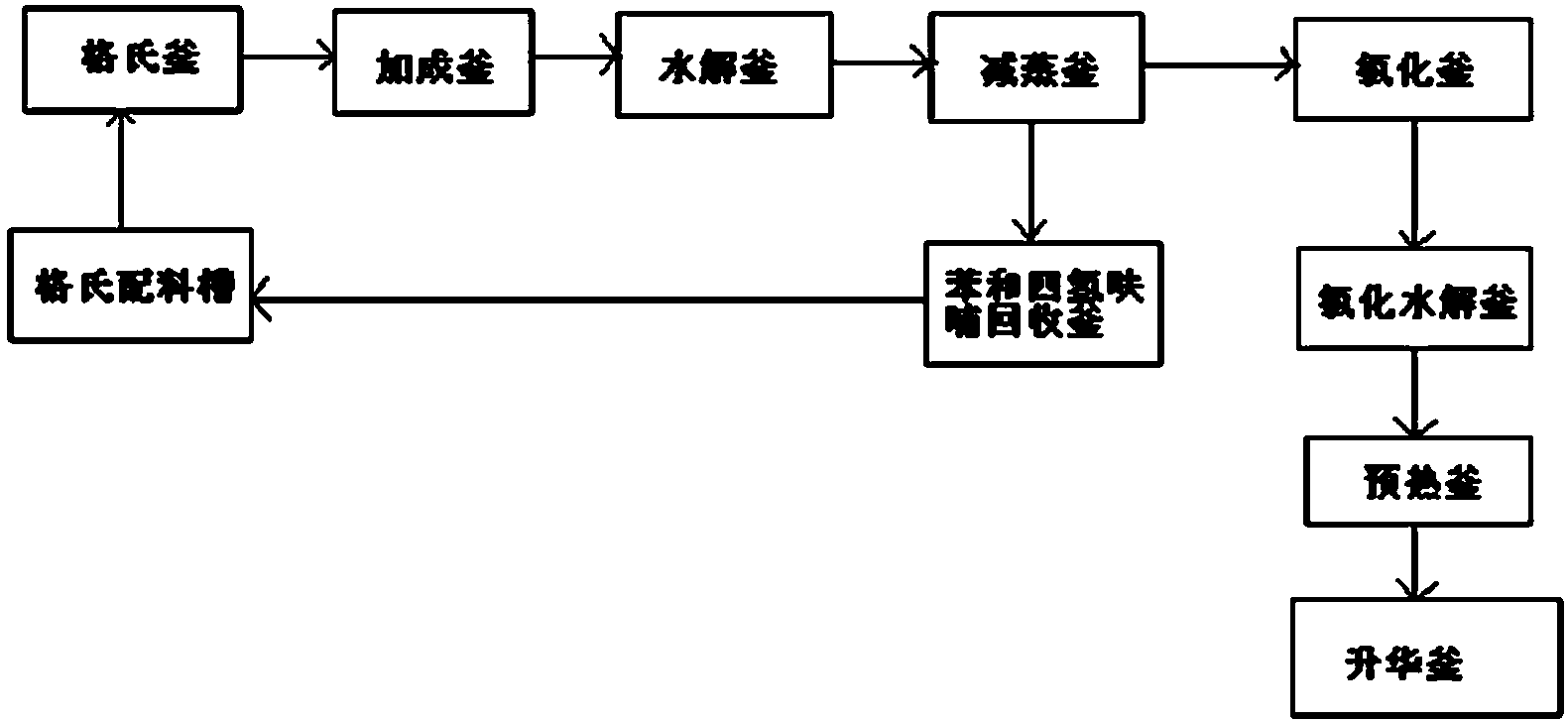

Method used

Image

Examples

Embodiment Construction

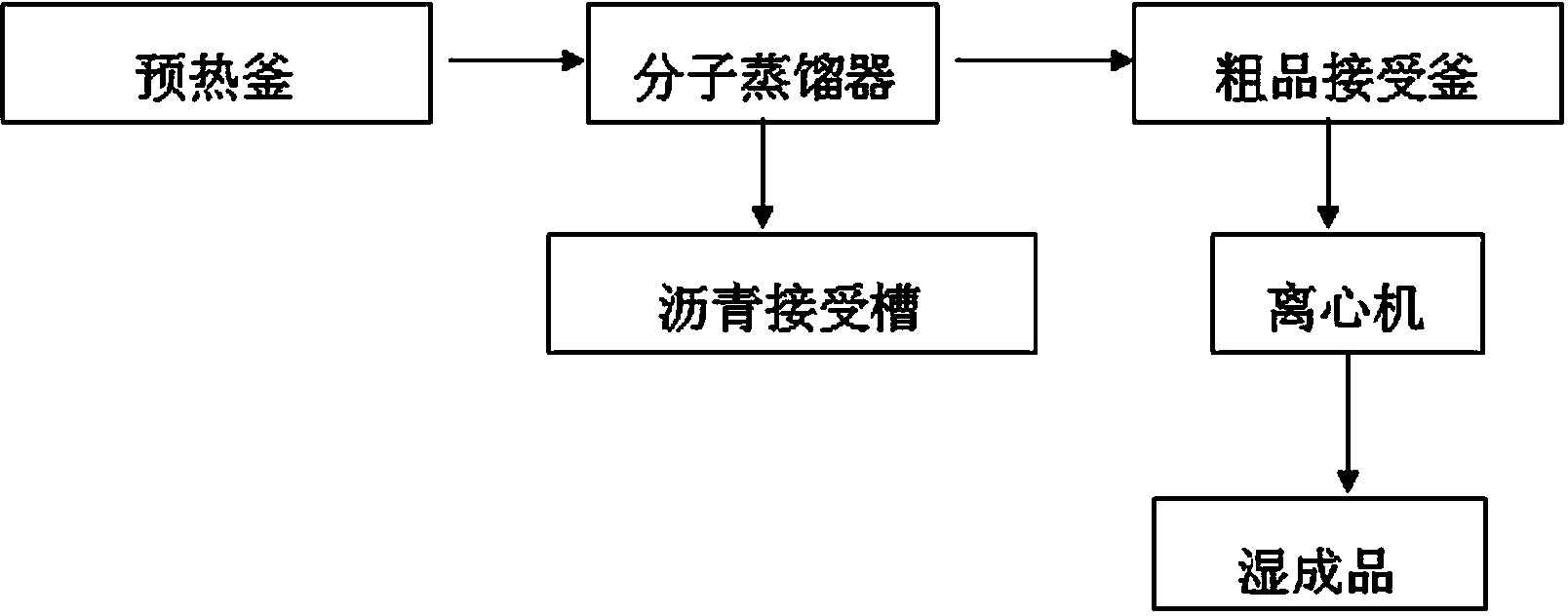

[0016] Such as image 3 As shown, replace the sublimation kettle with a molecular still, heat the asphalt (chlorinated hydrolyzate) in the preheater to 90°C, bring it to the molecular separator with a vacuum, open the oil temperature valve to heat up, and then slowly evacuate to 0.05 Below P, when the temperature reaches 110°C to 120°C, add 1000L of water to the crude product receiver and start separation. After 3.5 hours, the separation is completed, and then the by-products are scraped from the molecular separator with a scraper and discharged to the receiving tank and sent to the waste treatment station for processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com