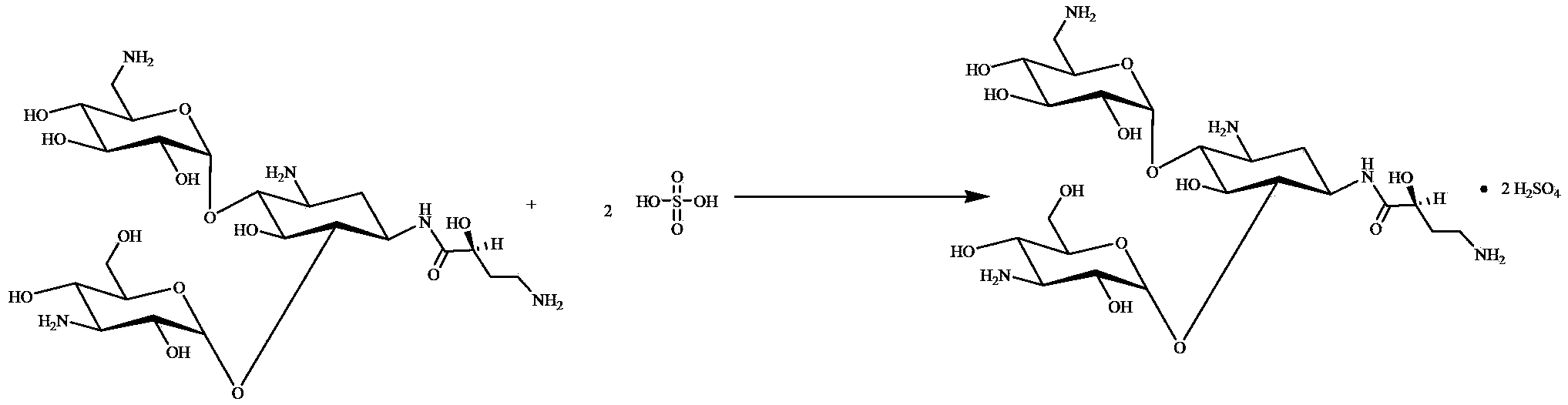

Method for preparing amikacin sulfate through amikacin

A technology of amikacin sulfate and amikacin is applied in the field of medicine to achieve the effects of improving stability, reducing degradation and reducing the generation of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

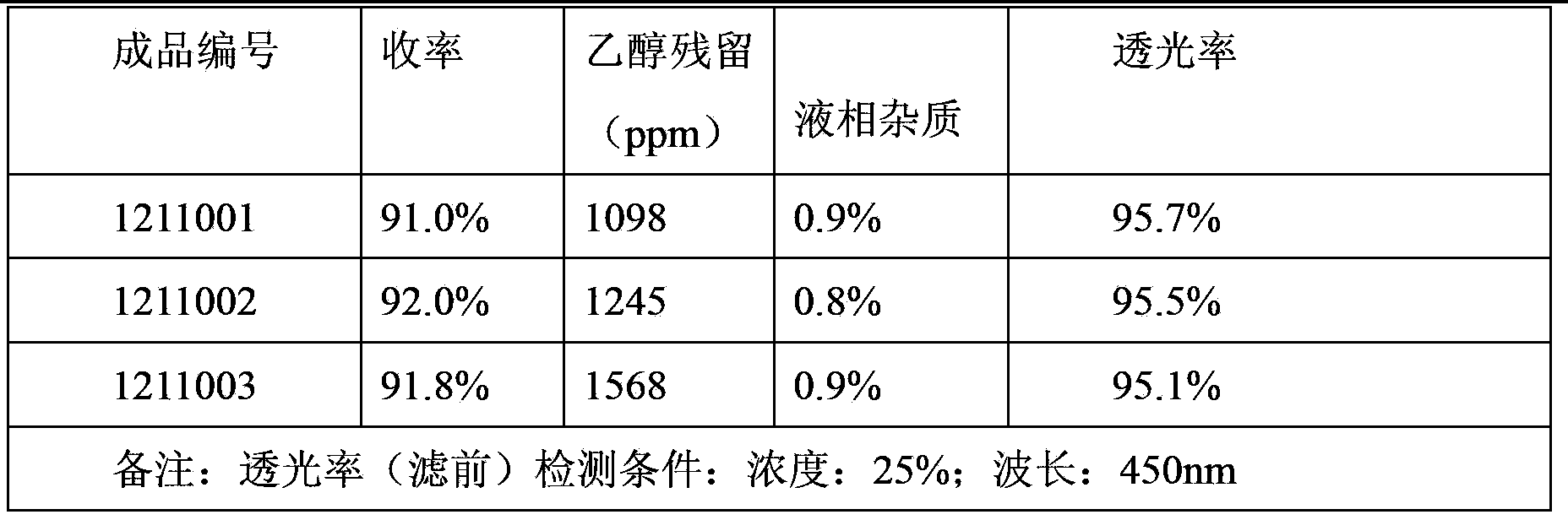

Embodiment 1

[0014] Take 200mL of amikacin solution with a concentration of 40%, transfer it into a 1000mL three-neck flask, stir, add sulfuric acid to adjust the pH value of the feed solution to 0.2, first add 100ml of 95% ethanol, heat to reflux, then add 600ml of ethanol, and cool down to 20°C , filtered with suction, put the obtained solid into a vacuum drying oven, control the inner temperature of the vacuum drying oven at 65-70°C, and bake for 4 hours to obtain amikacin sulfate (number: 1211001).

Embodiment 2

[0016] Take 200mL of amikacin solution with a concentration of 40%, transfer it into a 1000mL three-neck flask, stir, add sulfuric acid to adjust the pH value of the feed solution to 0.4, first add 100ml of 95% ethanol, heat to reflux, then add 700ml of ethanol, and cool down to 15°C , filtered with suction, put the obtained solid into a vacuum drying oven, control the inner temperature of the vacuum drying oven at 65-70°C, and bake for 4 hours to obtain amikacin sulfate (number: 1211002).

Embodiment 3

[0018] Take 200mL of 35% amikacin sulfate solution, transfer it into a 1000mL three-neck flask, stir, add sulfuric acid to adjust the pH value of the feed solution to 0.3, first add 100ml of 95% ethanol, heat to reflux, then add 800ml of ethanol, and cool down to 10°C , filtered with suction, the obtained solid was put into a vacuum drying oven, and the inner temperature of the vacuum drying oven was controlled at 65-70°C, and baked for 4 hours to obtain amikacin sulfate (number: 1211003).

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com