PU (polyurethane) synthetic leather vacuum tattoo machine

A vacuum embossing machine and synthetic leather technology, applied in textile and papermaking, fabric surface trimming, thorn pattern and other directions, can solve the problems of reducing the thickness of synthetic leather production materials, affecting production quality, losing original thickness, etc., to avoid springback Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

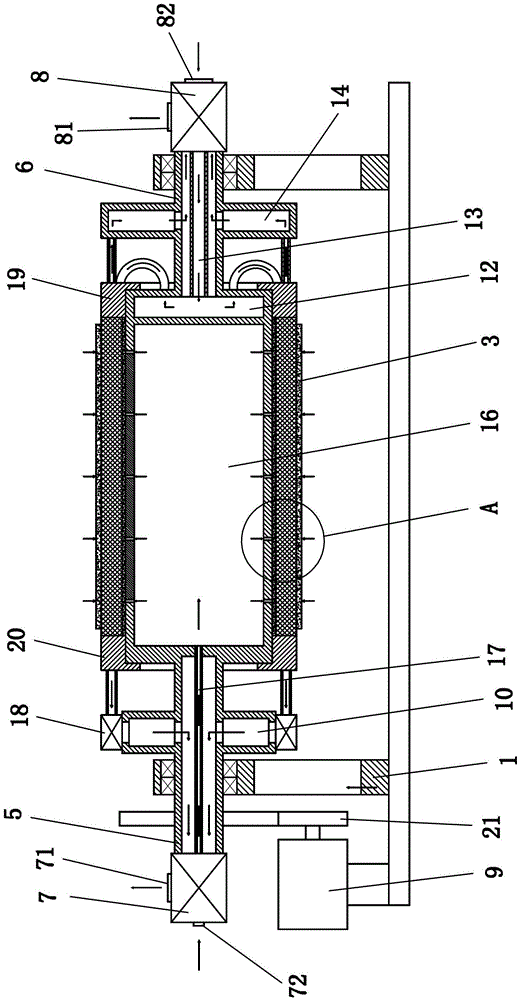

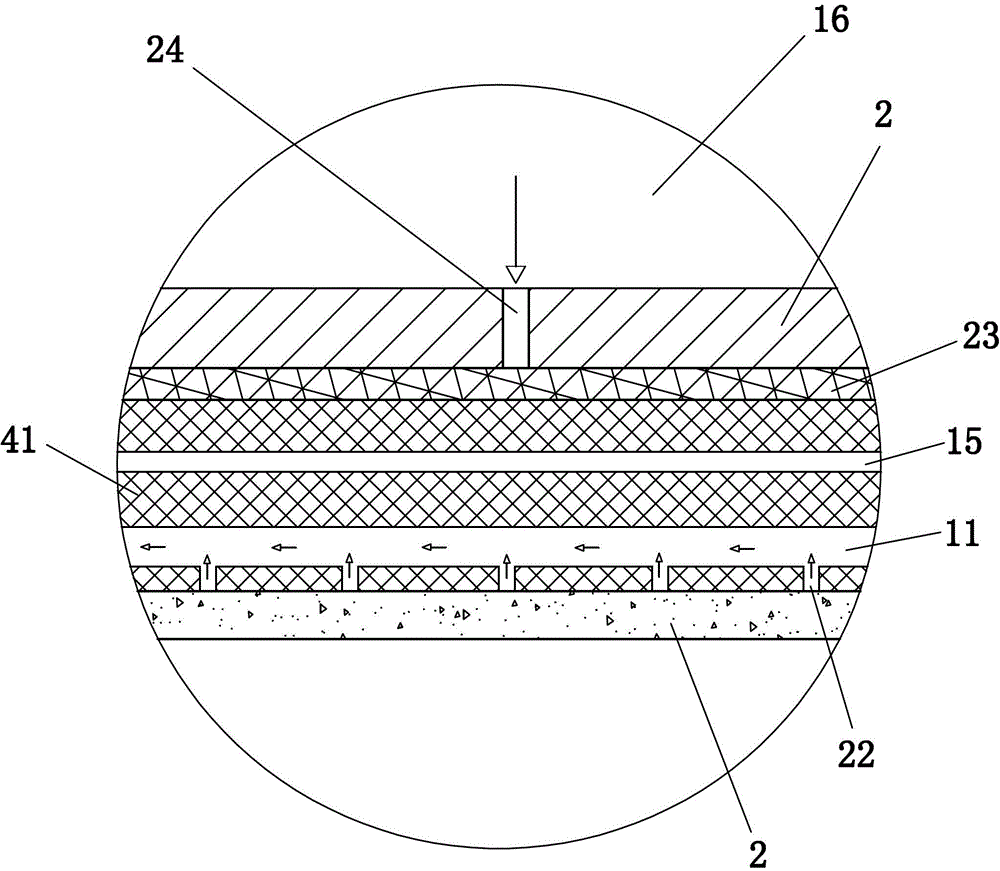

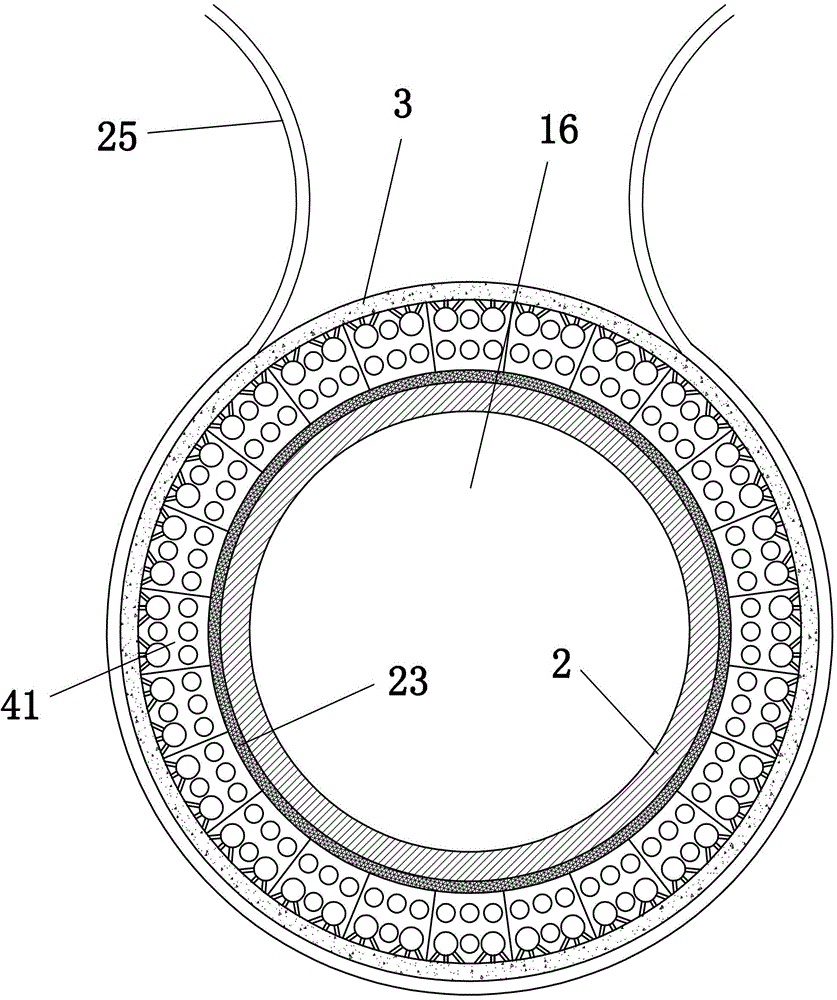

[0027] Such as figure 1 As shown, a PU synthetic leather vacuum embossing machine includes a frame 1, a roller 2 is installed in the middle of the frame 1, one end of the roller 2 is coaxially fixed with a rotating mandrel 5 for air, and the other end is coaxially fixed There is a rotating mandrel 6 for water. The rotating mandrel 5 for gas, the roller 2 and the rotating mandrel 6 for water can rotate relative to the frame 1, and the motor 9 is used to drive the rotating mandrel 5 for gas to rotate through the gears 21 meshing with each other. The outer side of the roller 2 is covered with a leather sheath 23, the outer side of the leather sheath 23 is covered with a fixed assembly 4, and the outer side of the fixed assembly 4 is covered with a ventilating pattern cylinder 3, the ventilating pattern cylinder 3 is made of ceramics, and the surface is made into the A molded side of the desired synthetic leather texture. The length of the roller 2 is greater than the length of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com