Diamond core bit

A diamond and core technology, used in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of easy wear of the sharp teeth, reduce the life of the drill bit, and the inability of the drill bit to effectively discharge powder, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

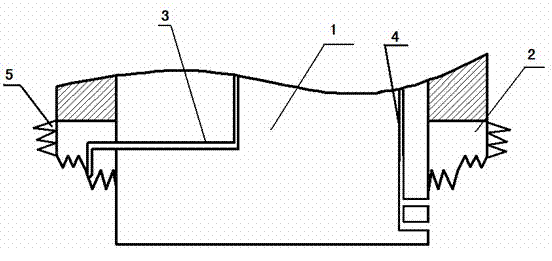

[0008] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0009] Referring to accompanying drawing, a kind of diamond core drill bit, comprises diamond matrix 1, is provided with cutting unit 2 in diamond matrix 1, is characterized in that, is provided with the outlet pipe 3 leading to cutting unit 2 in diamond matrix 1 and The powder discharge hole 4 is provided with a side cutting unit 5 on the side of the cutting unit.

[0010] The working principle of the present invention is:

[0011] When in use, the diamond matrix 1 drives the cutting unit 2 and the side cutting unit 5 to rotate at high speed, and the water outlet pipe 3 sprays water through the cutting unit 2 to reduce the temperature of the cutting unit at regular intervals, and the drilled powder is passed through the exhaust pipe at the same time. Get rid of in the space of powder hole and cutting unit 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com