Tunnel secondary lining back arch grouting pipe reserving system

A technology of secondary lining and grouting pipe, applied in tunnel lining, tunnel, wellbore lining, etc., can solve the problems of large thickness deviation of secondary lining, pollution of secondary lining, outflow of cement slurry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]

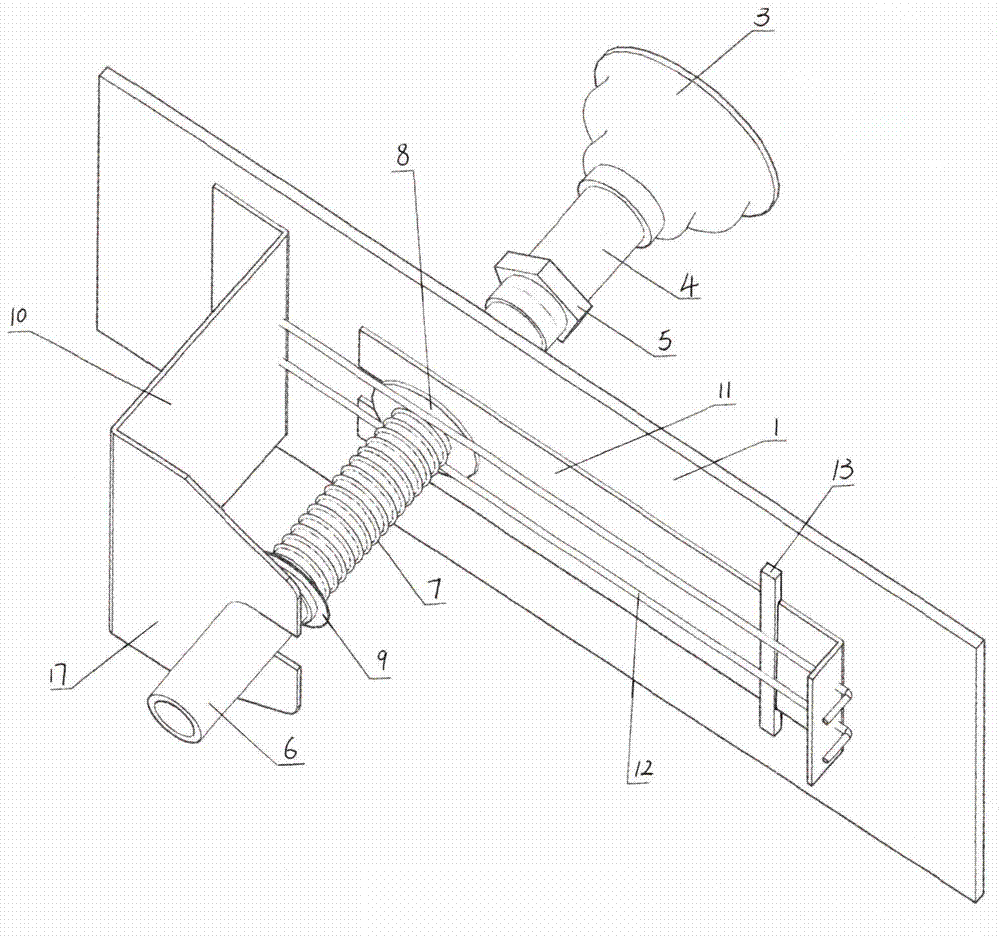

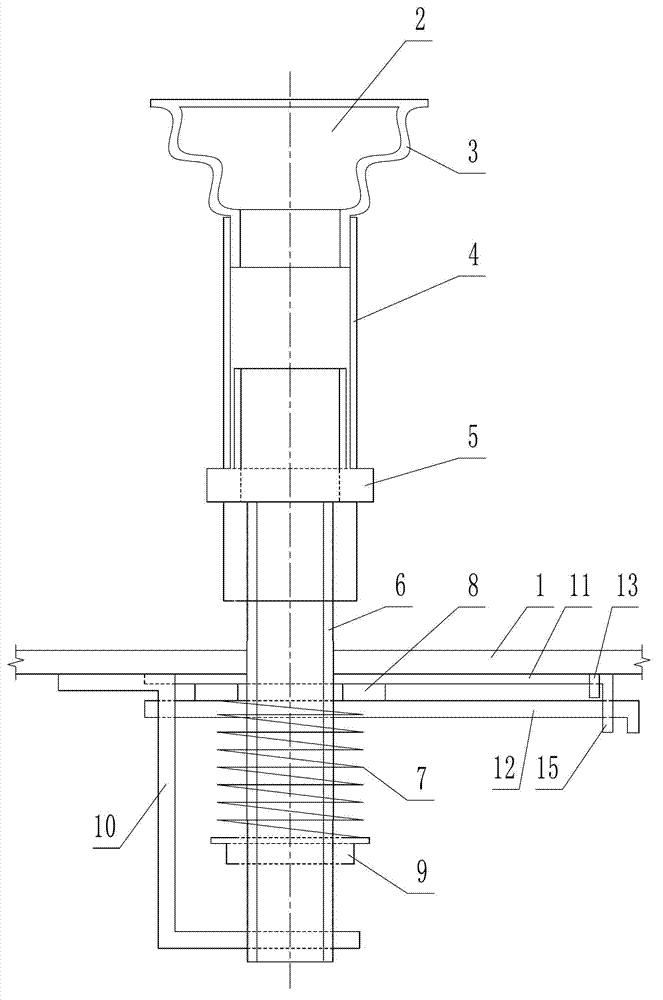

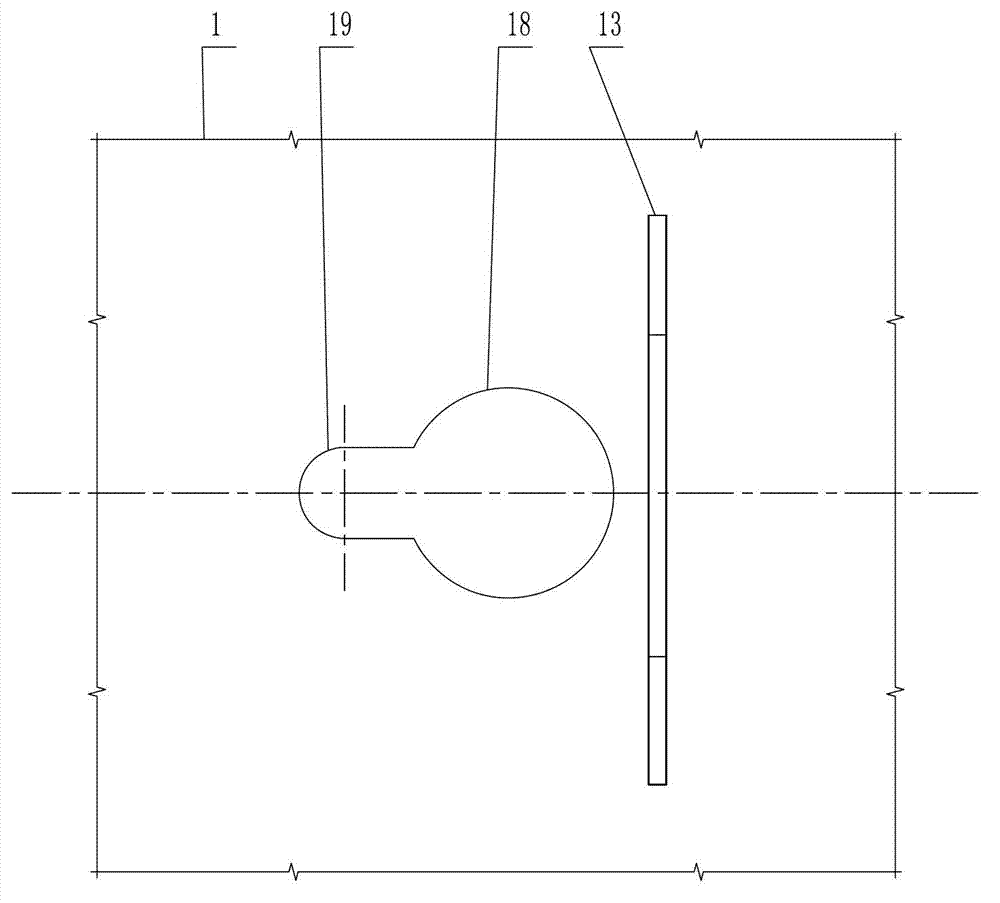

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, the reserved grouting pipe system for the tunnel secondary lining arch back of the present invention includes a lining trolley panel 1, an elastic cushion body 3 with a longitudinal through hole 2, a connecting pipe 4, a wire joint 5, and a grouting pipe 6 , wherein the elastic cushion body 3, the connecting pipe 4, the threaded joint 5, and the grouting pipe 6 are installed and connected sequentially from top to bottom, the connecting pipe 4 communicates with the longitudinal through hole 2 of the elastic cushion body 3, and the lower end of the grouting pipe 6 Penetrate the lining trolley panel 1 and extend downwards. The grouting pipe 6 is located on the outer wall below the lining trolley panel 1. A spring 7 is installed on the outer wall. The top of the spring 7 is fixedly connected with the lining trolley panel 1. The bottom end of the spring 7 is connected to The g...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap