Hydraulic drive pressure reducing valve for wind tunnel

A pressure reducing valve and hydraulic technology, applied in the field of pressure reducing valves, can solve the problems of inability to adjust the pressure in the wind tunnel and fail to meet the requirements, and achieve the effects of short fully open and fully closed times, reduced test costs, and low friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The principles and features of the present invention will be described in detail below in conjunction with the accompanying drawings.

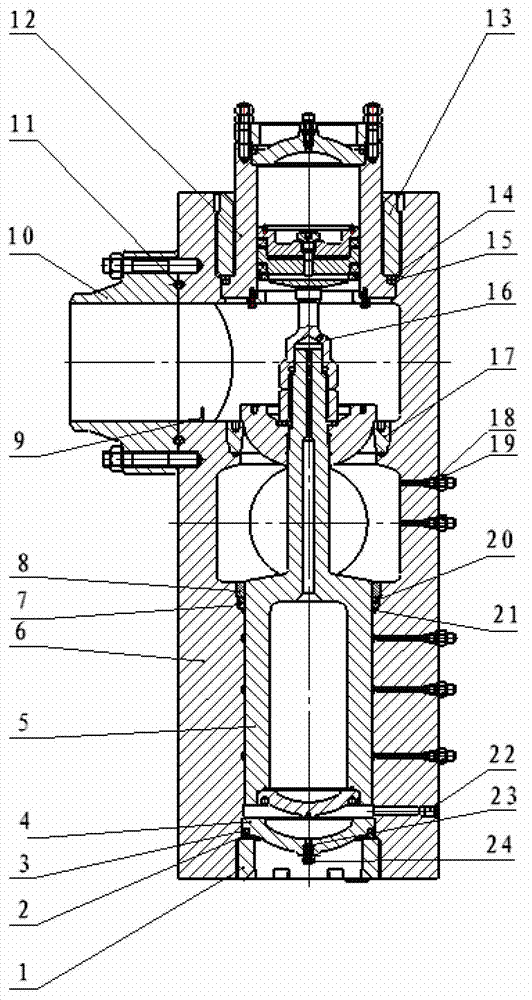

[0016] Such as figure 1 As shown, the hydraulically driven pressure reducing valve of the present invention includes: nut 1, backing ring 2, sealing ring 3, lower cover 4, pressure regulating piston 5, valve body 6, backing ring 7, movable nut 8, retaining ring 9, method Lan 10, gasket 11, closing piston 12, nut 13, backing ring 14, sealing ring 15, rod 16, disc seat 17, sealing ring 18, nozzle 19, sealing ring 20, felt ring 21, oil pipe nozzle 22, sealing Ring 23 and nozzle 24. When the pressure reducing valve is closed, the closing piston 12 will press the pressure regulating piston 5 tightly through the rod 16. When the pressure reducing valve is opened, the gas flow will be injected through the air inlet of the pressure reducing valve, and the pressure regulating piston 5 will inject hydraulic pressure through the oil nozzle 22 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com