Hot-blast stove with multiple spraying holes

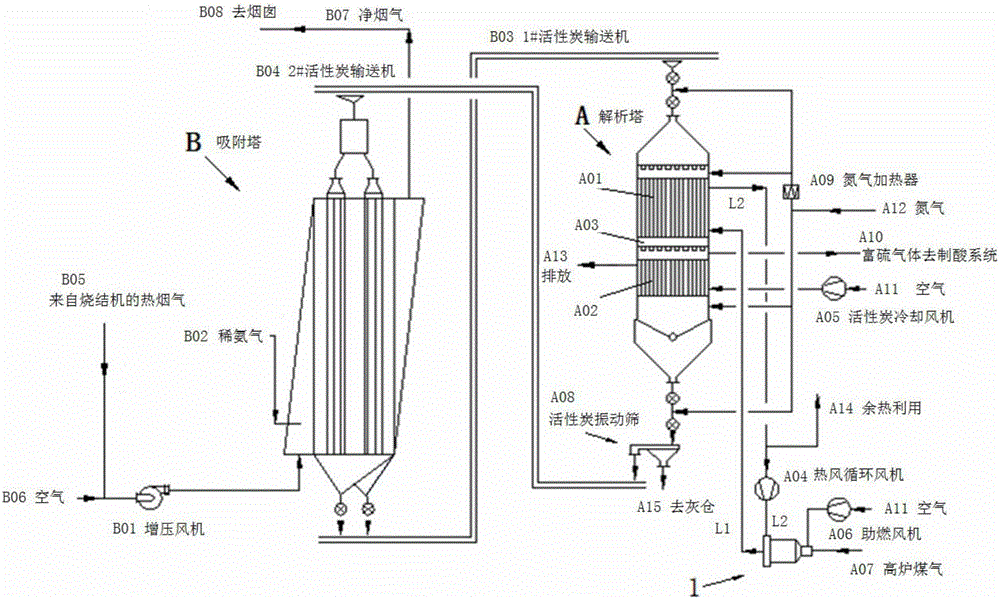

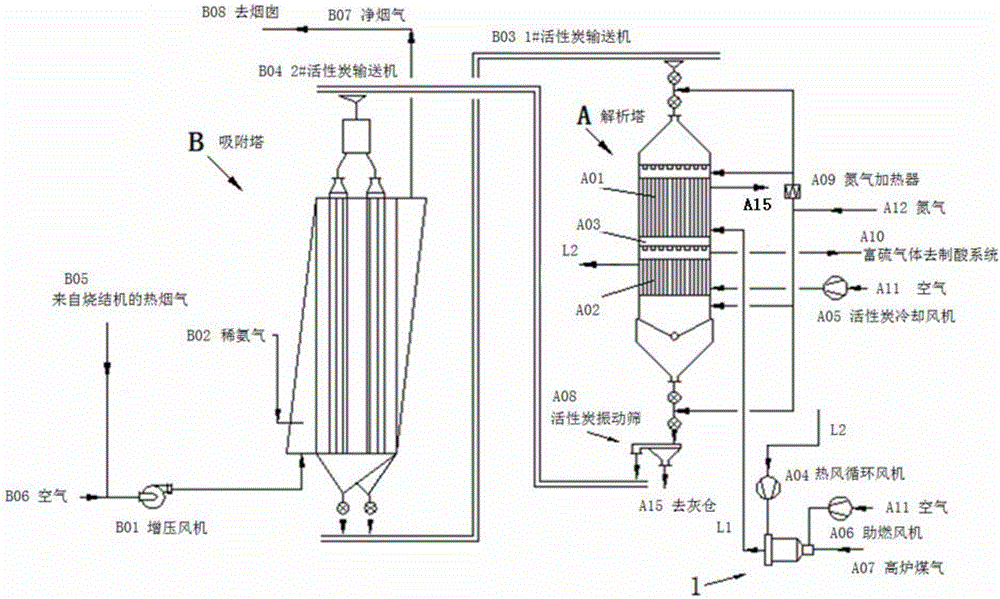

A technology of hot blast stove and spray hole, which is applied in the direction of air heater, fluid heater, lighting and heating equipment, etc. It can solve the problems of large mixing space, poor mixing air uniformity, and not suitable for vertical arrangement, so as to reduce the weight of equipment, Effect of reducing NOx generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

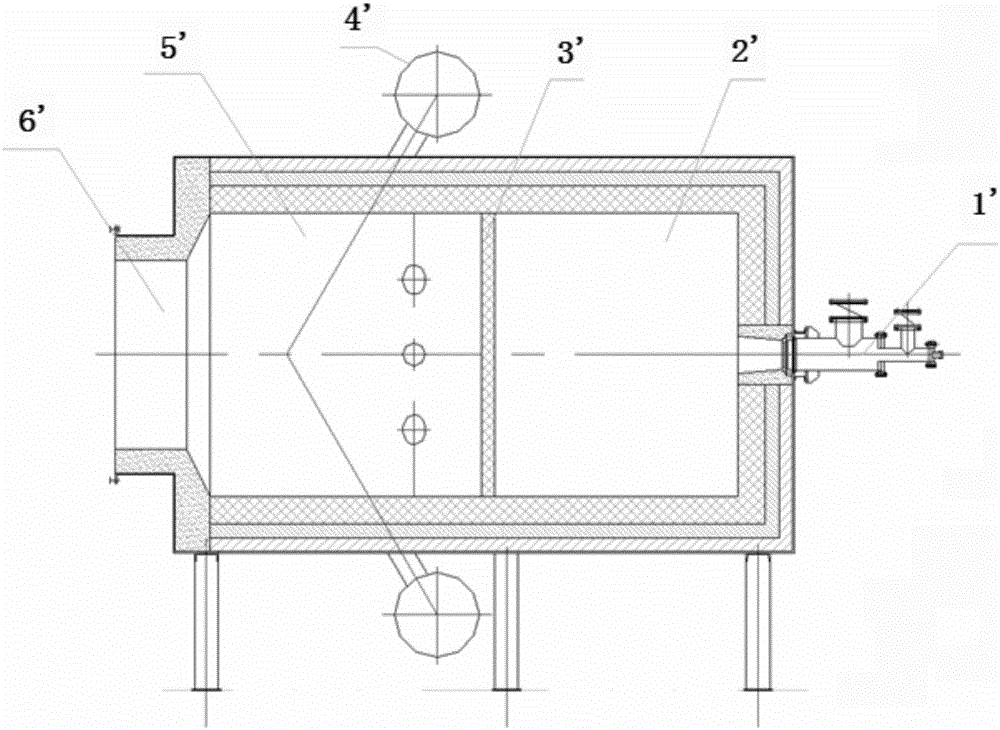

Embodiment 1

[0092] Such as Figure 4 and 5 As shown, a multi-nozzle type hot blast stove 1 adopts a horizontal arrangement, including a combustion section 2 and an air mixing section 3, the front end of the combustion section 2 is provided with a main burner 4; the side of the combustion section 2 is provided with a circulating air guide Air duct 5, automatic ignition burner 9 and temperature probe 10. The front end of the air mixing section 3 is sealed and connected to the rear end of the combustion section 2 , and the rear end of the air mixing section 3 is provided with a first hot air outlet 304 . A circulating air inlet 6 is provided on the side wall of the air mixing section 3 , and the air mixing section 3 includes an outer cylinder 301 , a multi-nozzle air mixing cylinder 302 as an inner cylinder, and an annular space 303 between them. A circulating air inlet 6 is provided on the wall of the outer cylinder 301 of the air mixing section 3 , and the circulating air inlet 6 is conn...

Embodiment 2

[0098] Such as Image 6 and 7 As shown, a multi-nozzle type hot blast stove 1 adopts a horizontal arrangement, including a combustion section 2 and an air mixing section 3, the front end of the combustion section 2 is provided with a main burner 4; the side of the combustion section 2 is provided with a circulating air guide Air duct 5, automatic ignition burner 9 and temperature probe 10. The front end of the air mixing section 3 is sealed and connected to the rear end of the combustion section 2 , and the rear end of the air mixing section 3 is provided with a first hot air outlet 304 . A circulating air inlet 6 is provided on the side wall of the air mixing section 3 , and the air mixing section 3 includes an outer cylinder 301 , a multi-nozzle air mixing cylinder 302 as an inner cylinder, and an annular space 303 between them. A circulating air inlet 6 is provided on the wall of the outer cylinder 301 of the air mixing section 3 , and the circulating air inlet 6 is conne...

Embodiment 3

[0102] Such as Figure 8-9 As shown, adopt the same design as in Embodiment 1, but the multi-nozzle type hot blast stove 1 adopts vertical setting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com