Bi elementary substance nanostructured materials and preparation method and application thereof

A nanostructure and elemental technology, applied in the direction of electrochemical variables of materials, etc., can solve the problems such as the lack of widespread development and the lack of Bi elemental nanostructured materials, and achieve the effect of facilitating industrial production, fewer steps, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

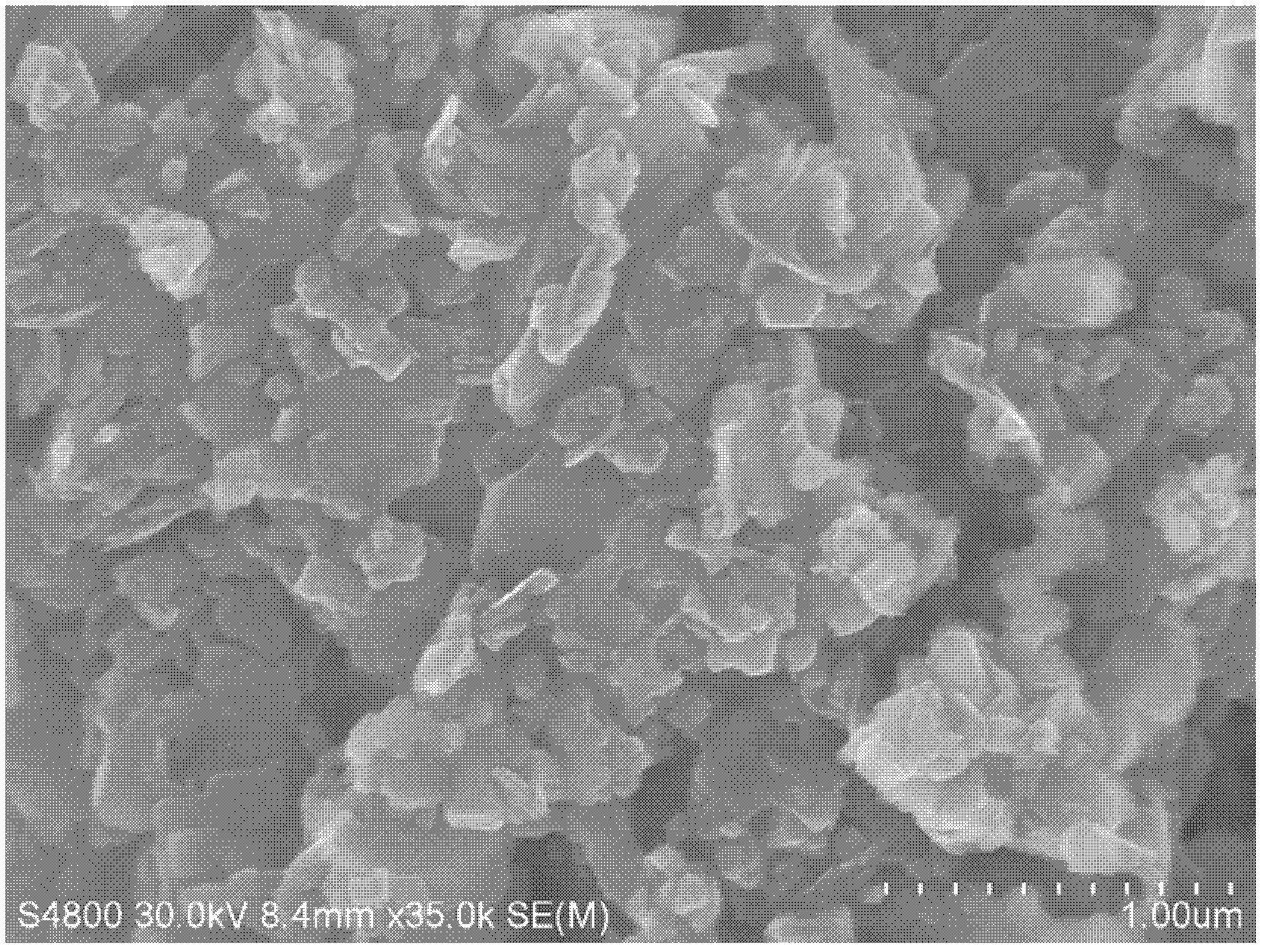

[0021] Embodiment 1, preparation Bi elemental nanostructure material

[0022] Dissolve 0.4g of surfactant Pluronic F127 in 50g of water, first add 2.06g of hydrazine hydrate, then disperse 0.36g of bismuth chloride in it, stir and mix to obtain a suspension. The obtained suspension is transferred into a polytetrafluoroethylene-lined stainless steel hydrothermal reaction kettle with a capacity of 80ml (the reaction kettle is resistant to acid and alkali, corrosion resistance, and high temperature) and sealed, and heated at 165°C in an oven for 3 hours, and the reaction is over. Finally, the reaction product was centrifuged at a speed of 8000 rpm for 15 minutes, and the upper layer liquid was discarded to obtain a centrifuged product. After the centrifuged product was ultrasonically cleaned with excess ethanol for 8 minutes, it was centrifuged at a speed of 8000 rpm. After 15 minutes, the upper layer liquid was discarded, and the obtained black solid product was transferred to a...

Embodiment 2

[0025] Embodiment 2, preparation Bi elemental nanostructure material

[0026] Dissolve 0.5g of surfactant Pluronic F127 in 50g of water, first add 2.06g of hydrazine hydrate, then disperse 0.2g of bismuth chloride in it, stir and mix to obtain a suspension. Transfer the obtained suspension into a polytetrafluoroethylene-lined stainless steel hydrothermal reaction kettle with a capacity of 80ml and seal it, and heat it in an oven at 170°C for 4 hours. Centrifuge for 15 minutes, discard the supernatant liquid, and obtain the centrifuged product. The centrifuged product was ultrasonically cleaned with excess ethanol for 8 minutes, centrifuged at a speed of 8000 rpm for 15 minutes, the upper layer liquid was discarded, the obtained black solid product was transferred to a watch glass, and dried at natural ambient temperature for 1 day , to obtain Bi simple substance nanostructure materials.

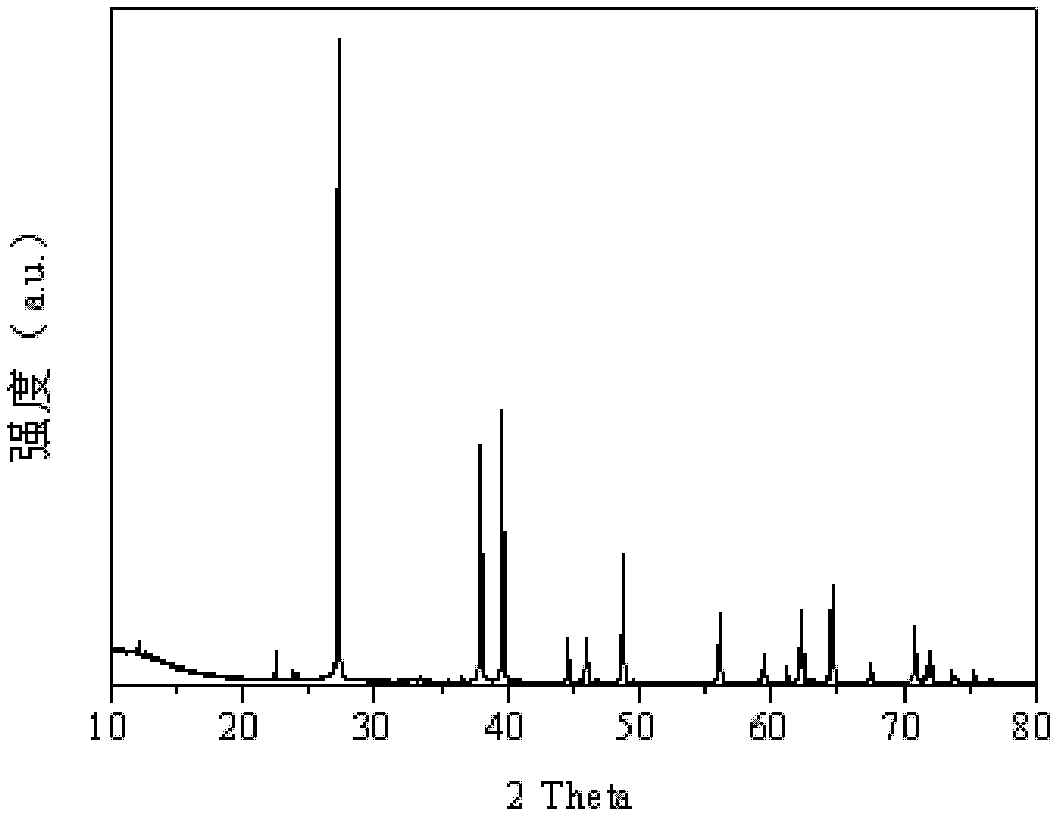

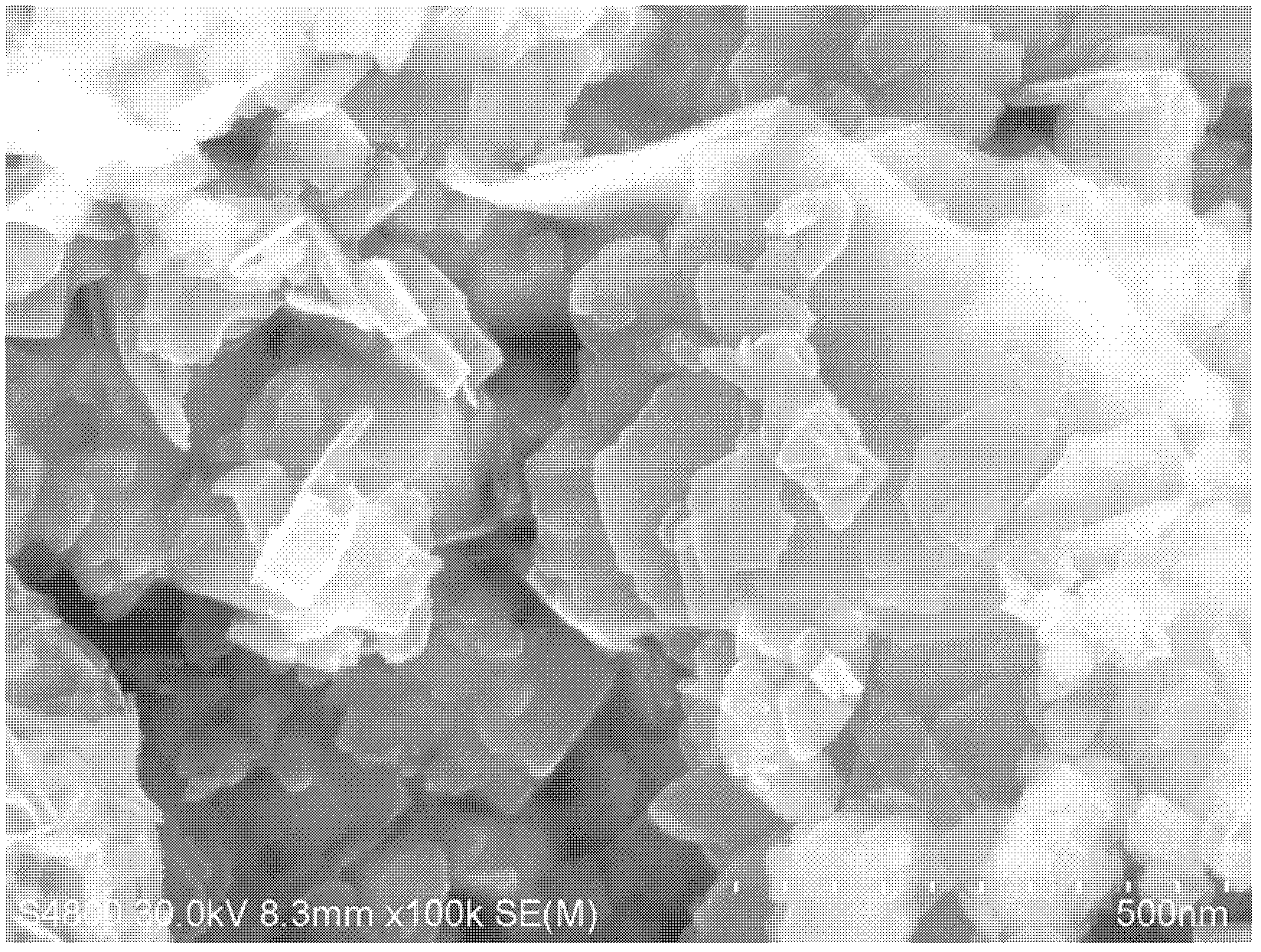

[0027] Bi elemental nanostructure materials were characterized by XRD, laser particle s...

Embodiment 3

[0029] Embodiment 3, preparation Bi elemental nanostructure material

[0030] Dissolve 0.35g of surfactant Pluronic F127 in 50g of water, first add 2.06g of hydrazine hydrate, then disperse 0.15g of bismuth chloride in it, stir and mix to obtain a suspension. The resulting suspension was transferred into a polytetrafluoroethylene-lined stainless steel hydrothermal reaction kettle with a capacity of 80 ml and sealed, then heated in an oven at 150° C. for 5 hours. After the reaction, the reaction product was centrifuged at 8000 rpm for 15 minutes, and the upper layer liquid was discarded to obtain the centrifuged product. The centrifuged product was ultrasonically cleaned with excess ethanol for 8 minutes, centrifuged at a speed of 8000 rpm for 15 minutes, the upper liquid was discarded, the obtained black solid product was transferred to a watch glass, and dried at natural ambient temperature and under ventilation for 1 day. Obtain Bi simple substance nanostructure material. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap