A hydraulic plug-type oil cylinder lifting system

A lifting system and pin-type technology, applied in the direction of fluid pressure actuating device, servo motor, servo motor assembly, etc., can solve the problems of high cost and complicated lifting system of self-elevating platform, so as to reduce production cost and simplify control. The effect of the oil circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

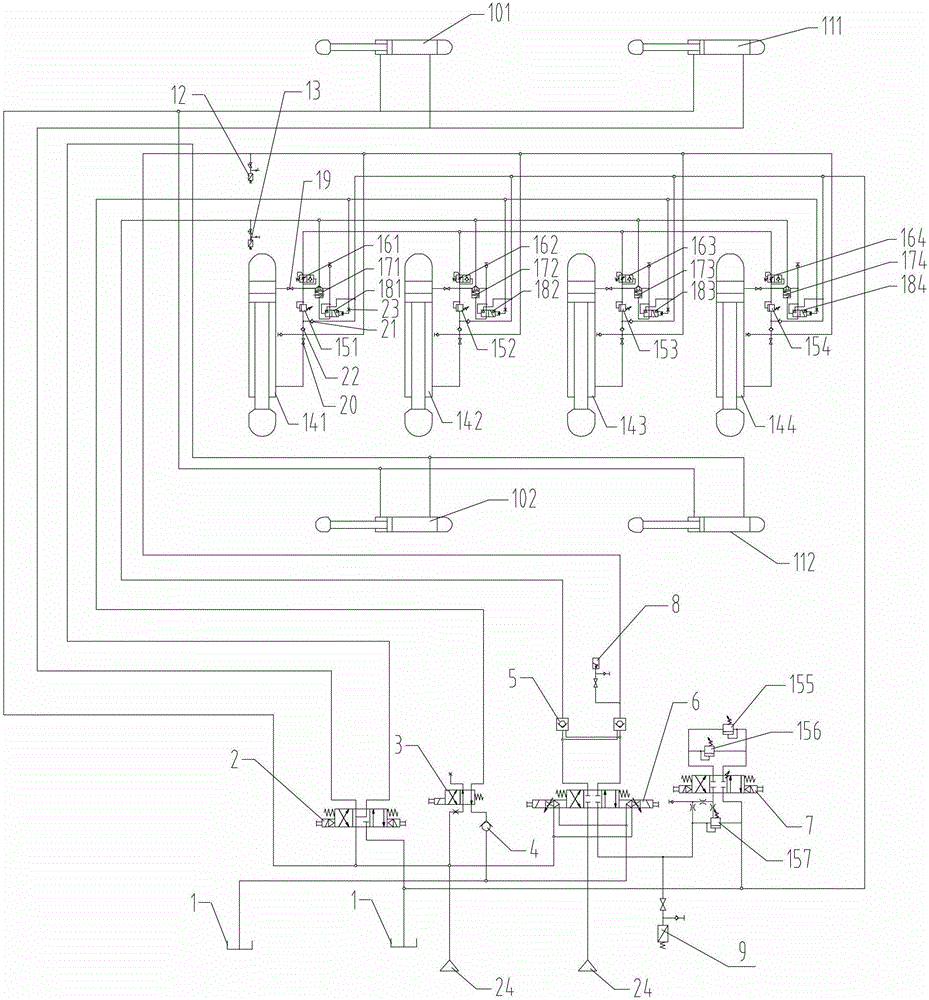

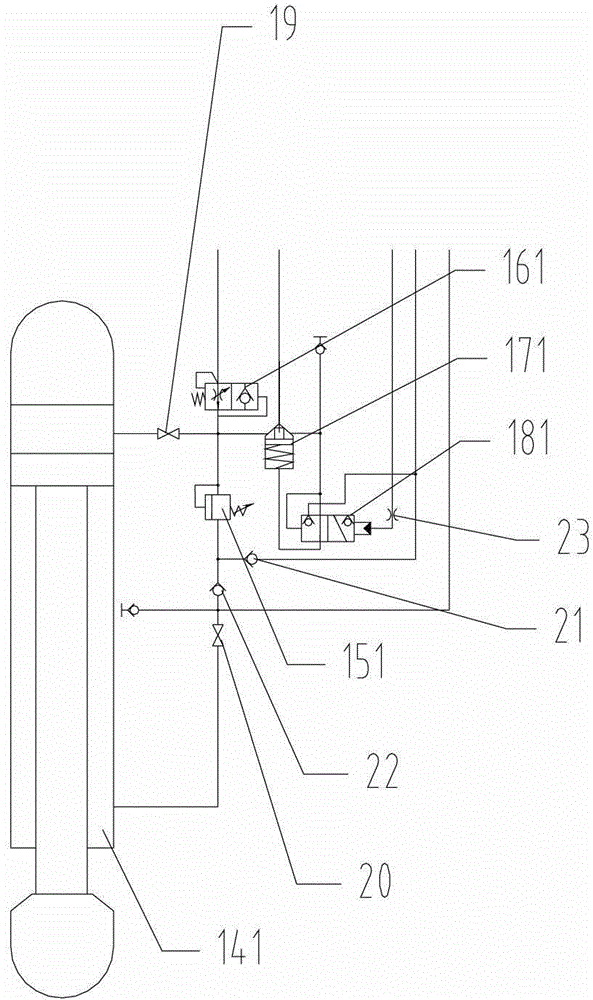

[0032] The embodiment of the present invention provides a hydraulic plug-type oil cylinder lifting system, such as figure 1 and figure 2 As shown, the lifting system includes: a first lifting cylinder 141, a first upper pin cylinder 101, a first lower pin cylinder 102, a three-position four-way reversing valve 2, a two-position four-way reversing valve 3, a first cartridge Valve 171, the first two-position three-way pilot valve 181 and three-position four-way electro-hydraulic reversing valve 6; the first oil port of the two-position four-way reversing valve 3 communicates with the oil inlet 24 of the lifting system, and the two-position four-way The second oil port of the directional reversing valve 3 is closed, the third oil port of the 2-position 4-way reversing valve 3 communicates with the oil inlet port of the first 2-position 3-way pilot valve 181, and the first 2-position 3-way pilot valve 181 The first oil outlet of the first cartridge valve 171 is connected with th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap