Hydraulic plunger variable duplex pump total power control method and system

A control method and technology of constant power control valve, applied in pump control, liquid variable capacity machinery, machine/engine, etc. Motion stuck, oil circuit layout and processing difficulty, etc., to achieve the effect of small part volume, small hydraulic damping, and reduced processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

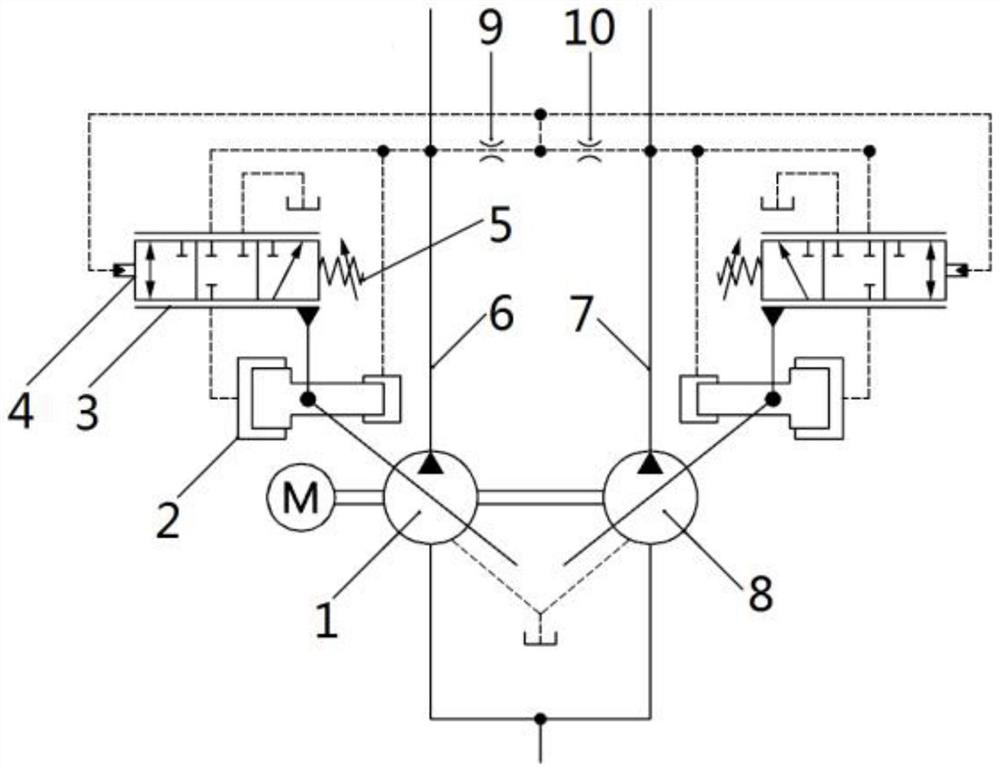

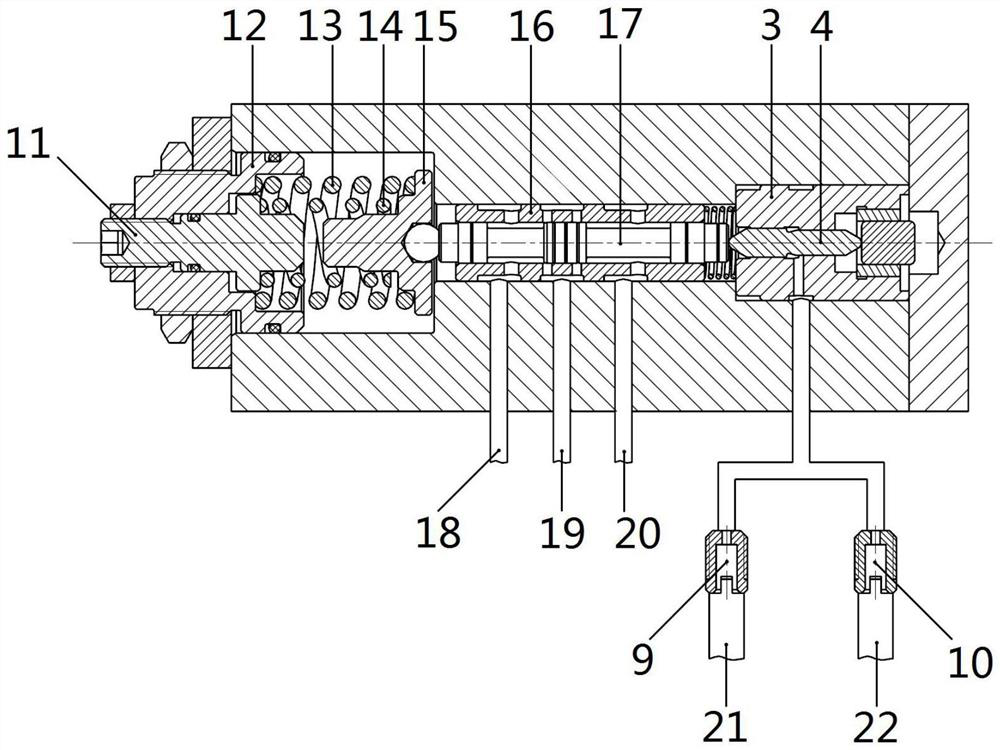

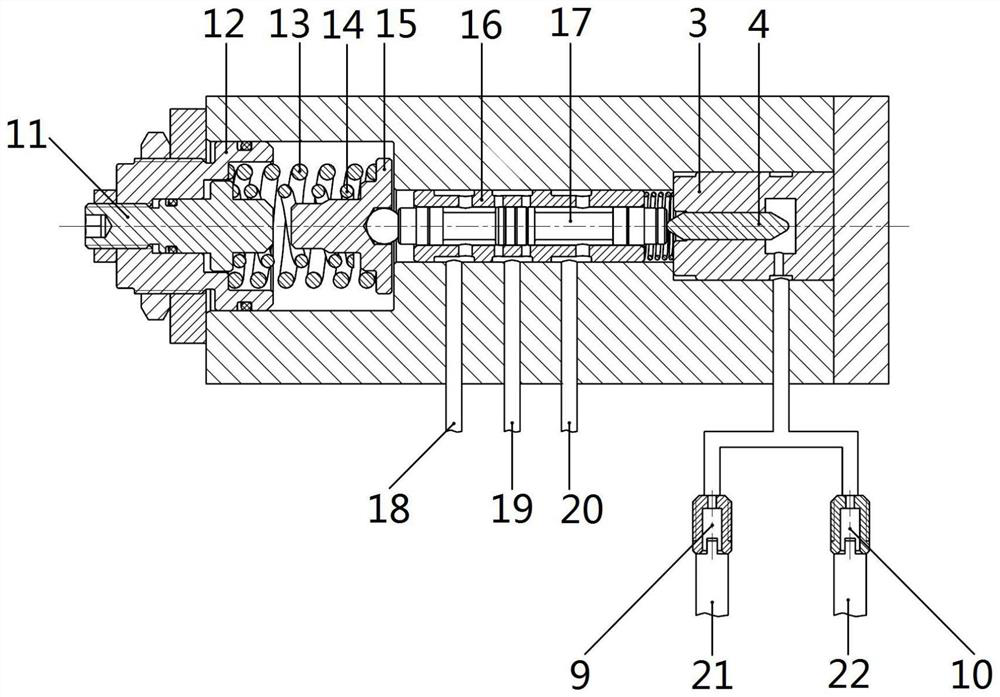

[0019] Example. A method for controlling the total power of a hydraulic piston variable displacement duplex pump, in which a first throttling plug and a second throttling plug are connected in series at the pressure oil at the outlet of the first pump and the second pump of the hydraulic plunger variable duplex pump, Through the function of two throttling plugs, the average pressure of the pressure oil at the outlet of the first pump and the outlet of the second pump is obtained, and the average pressure is respectively applied to the constant power control valve of the corresponding hydraulic plunger variable double pump total power control valve. On the power control valve, the total power control of the hydraulic plunger variable duplex pump is realized.

[0020] The constant power control valve...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap