Method of eliminating bending deflection of tufftriding forged steel crank shaft

A bending deformation and nitrocarburizing technology, applied in the field of nitrocarburizing forged steel crankshafts to eliminate bending deformation, can solve the problems of workpiece deformation, large axis bending deformation, scrapped crankshaft cracks, etc., to improve the qualification rate, reduce the amount of correction, avoid The effect of scrapped crankshaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0009] The crankshaft of the present invention is processed-pre-correction-cleaning-nitrocarburizing-runout inspection correction-magnetic flaw detection-cleaning.

[0010] The pre-calibration is to use a pressure straightening machine to correct the bending deformation of the intermediate journal of the crankshaft and control it within the range of ±0.01 of the vector center value, and the direction of the correction control is the opposite direction of the vector center value.

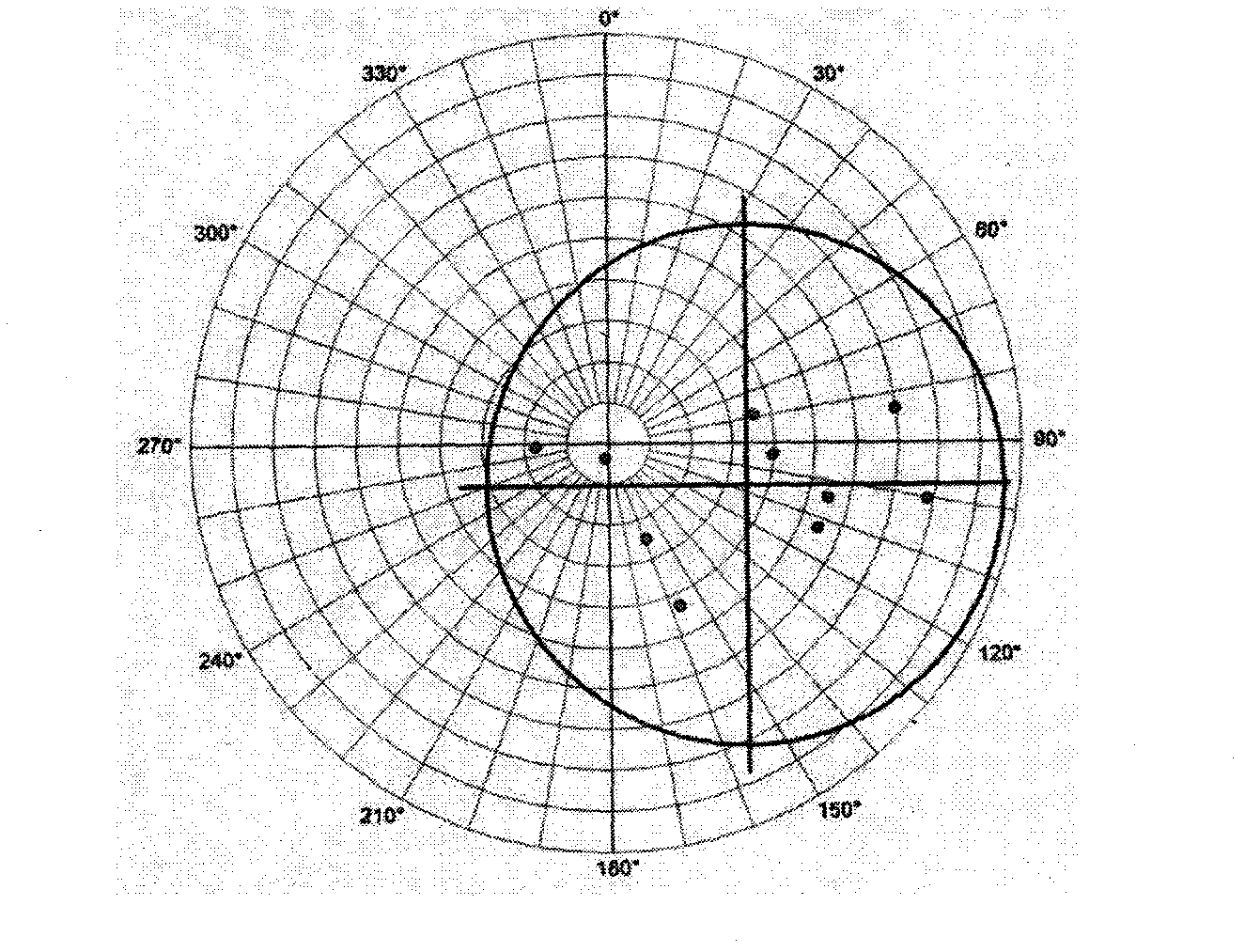

[0011] First take a batch of workpieces, at least 10 pieces for pre-test, process according to the crankshaft - cleaning - nitrocarburizing - runout inspection and correction - magnetic flaw detection - cleaning, the runout of the intermediate journal required to be machined before nitrocarburizing is ≤ 0.03. In the runout inspection and correction process, the distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com