Swing block die for handle machining

A mold and movable mold technology, applied in the field of pendulum block molds, can solve the problems of scrap, inner circle wrinkling and deformation, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

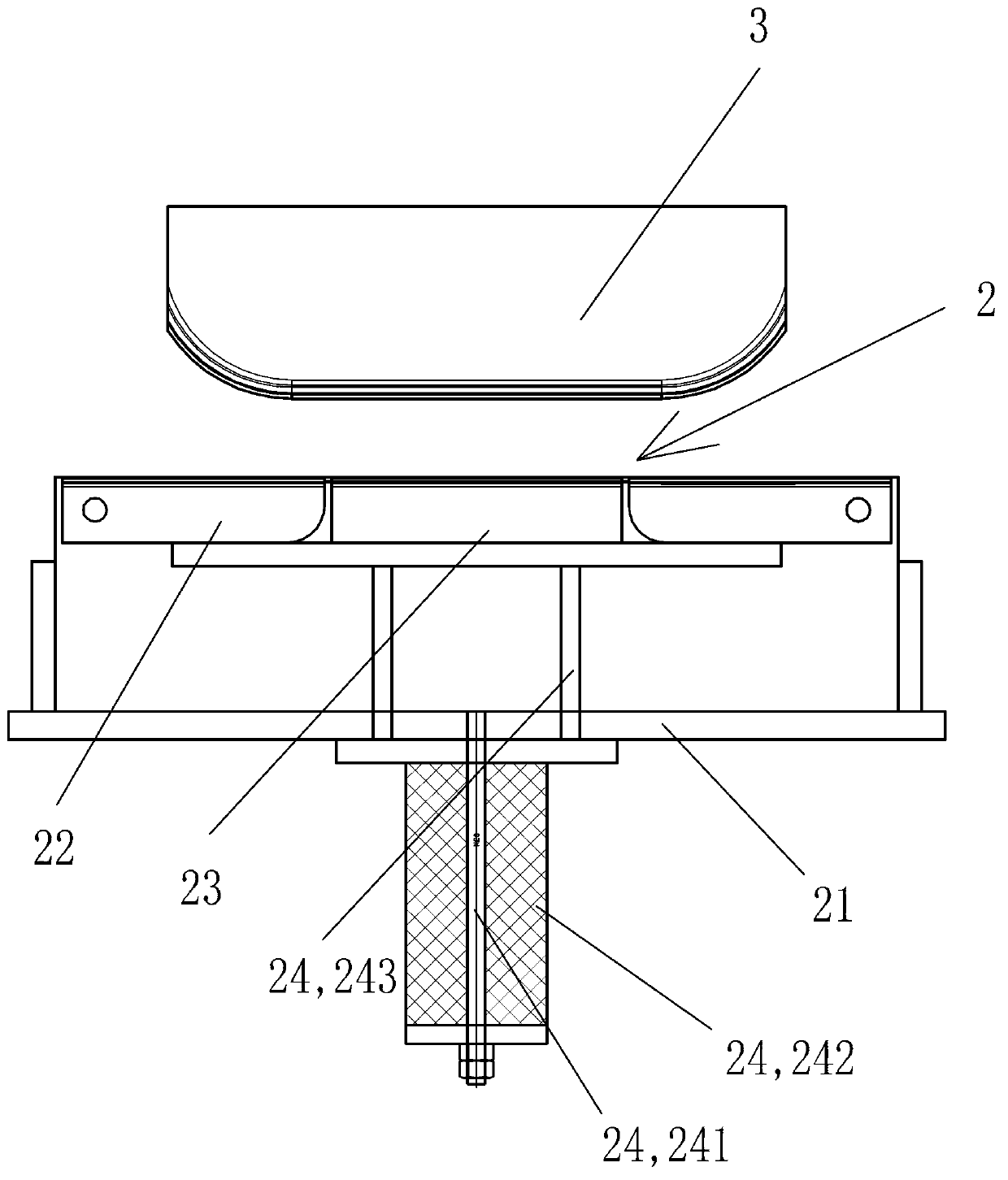

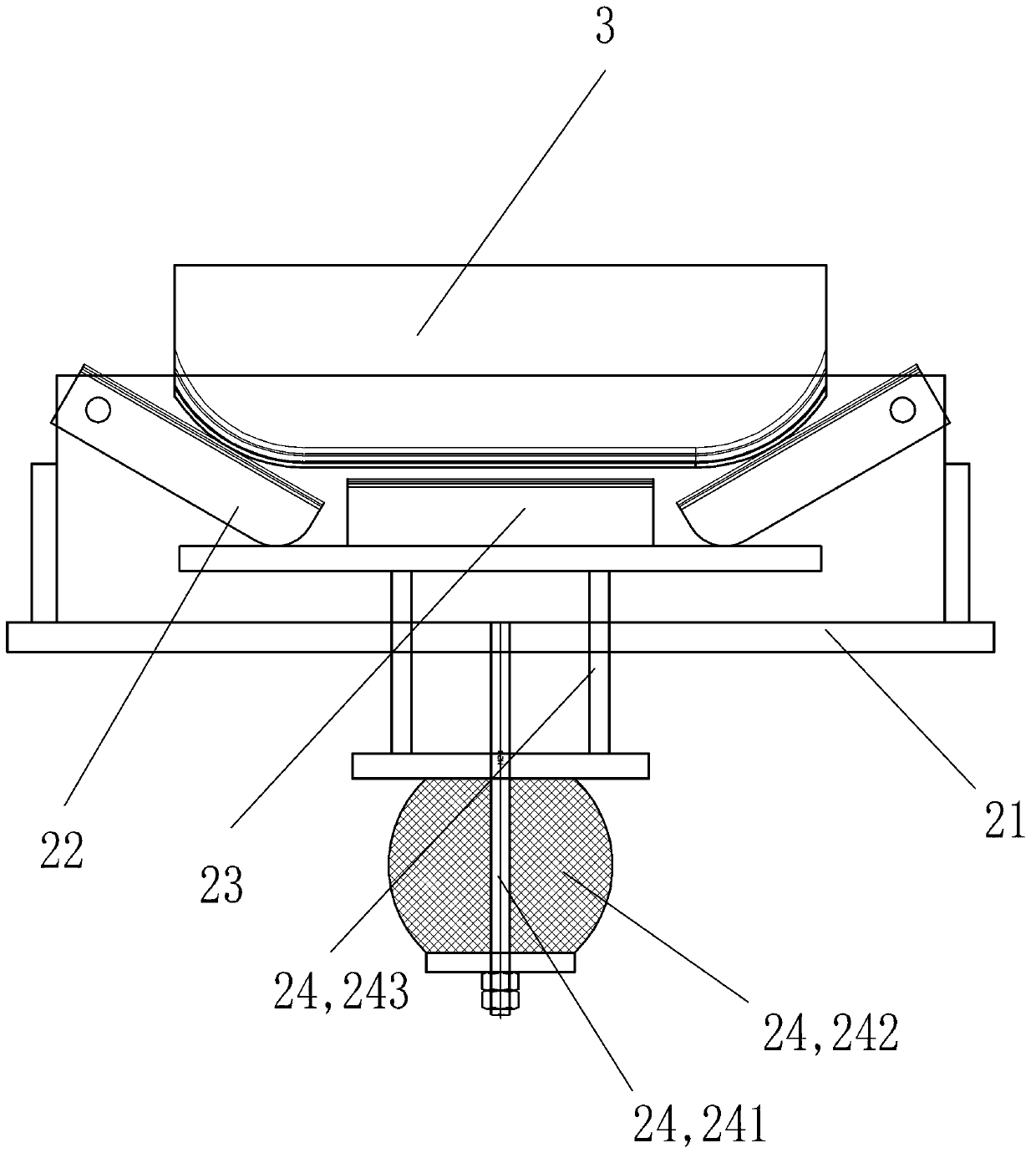

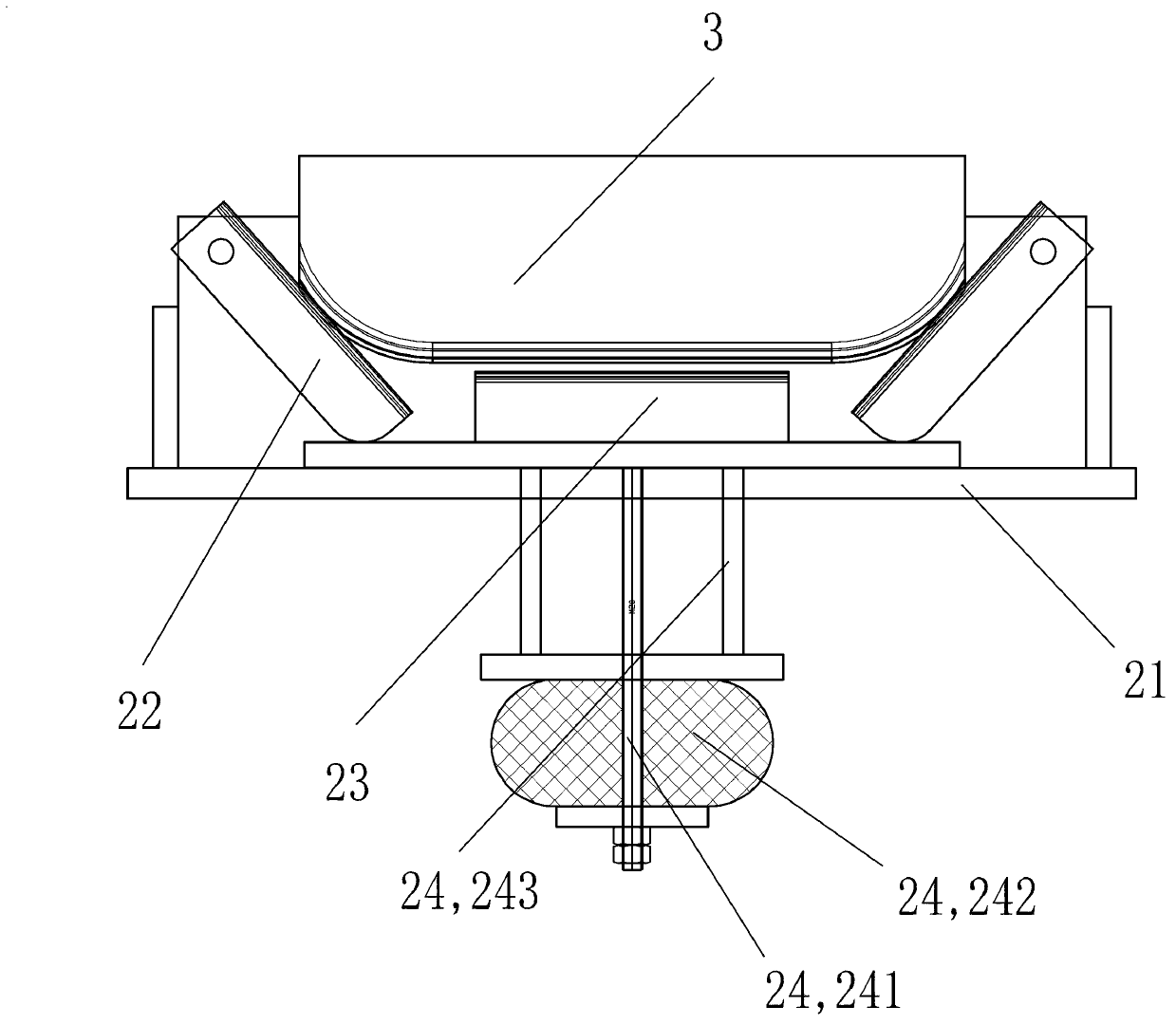

[0016] The pendulum block mold for processing the handle includes a mold platform assembly 2 and a movable mold 3 , the mold platform assembly 2 includes a mold platform assembly 2 and a movable mold 3 , and the mold platform assembly 2 includes a bracket 21 . The two sides of the support 21 are respectively hinged with a section pipe 1, and the two ends can be placed on a rotating block 22 thereon, and a support platform 23 is provided between the two rotating blocks 22 . At the bottom of the supporting platform 23, there is a telescopic component assembly 24 that shrinks when it is under pressure. The movable mold 3 is placed above the mold platform assembly 2, and a driving mechanism that drives it to move is provided on the movable mold 3. The driving mechanism generally adopts hydraulic pressure. cylinder to drive.

[0017] As a preferred manner, the rotating block 22 and the supporting platform 23 are located on the same plane.

[0018] As a preferred manner, the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com