Dismounting device for plug cover

A technology for dismantling devices and blocking covers, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., and can solve problems such as low work efficiency, difficulty in disassembly by operators, and lack of supporting equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

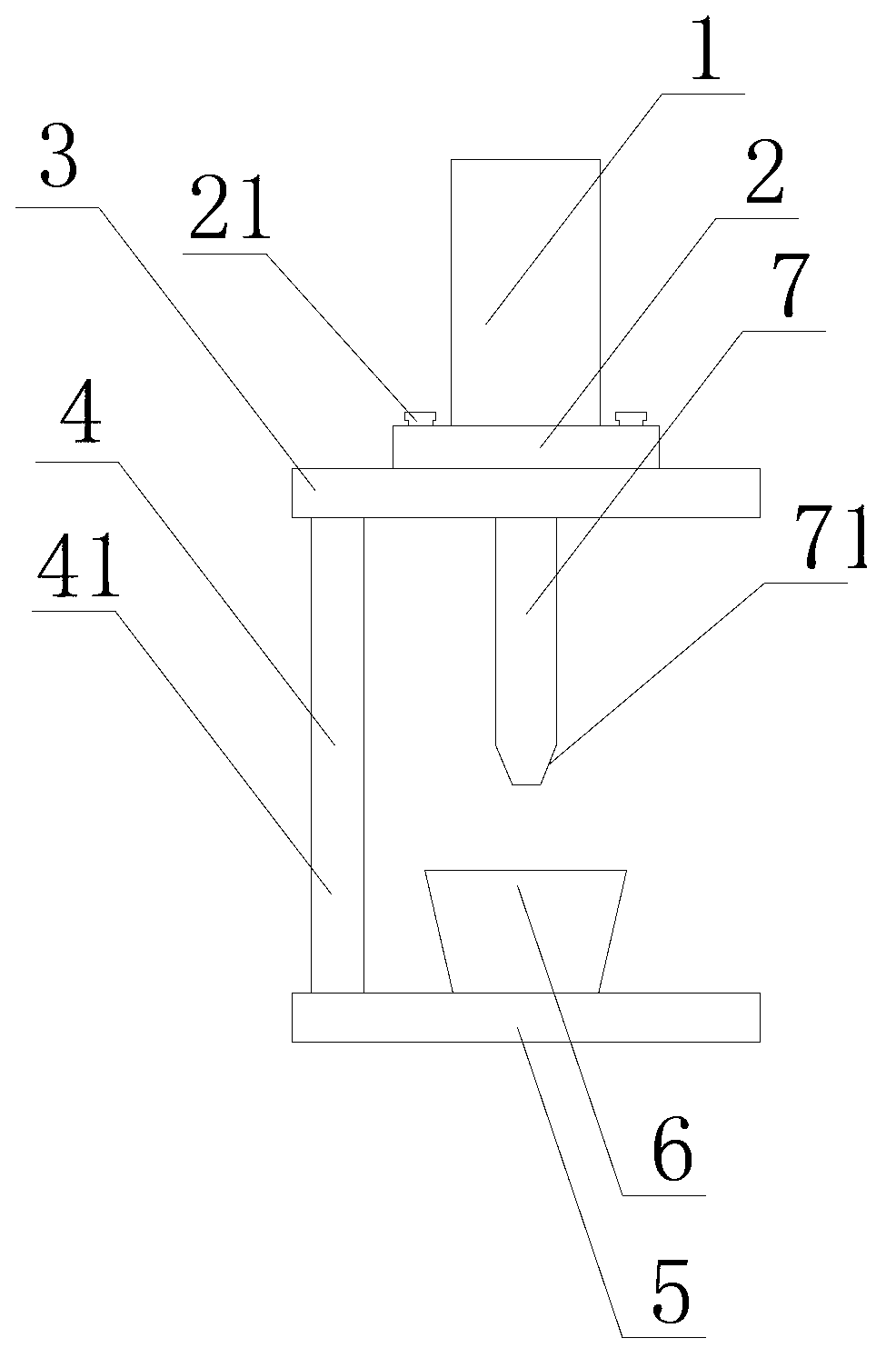

[0016] see figure 1 , the present invention relates to a blocking cover removal device, comprising an upper horizontal plate 3, a lower horizontal plate 5, a vertical plate 4 arranged between the upper horizontal plate 3 and the lower horizontal plate 5, and a vertical plate 4 on the upper horizontal plate There is a cylinder 1 on the side, which is connected to the upper horizontal plate through the mounting seat 2. It is provided with an air rod 7 that can reciprocate through the upper horizontal plate. The other end of the cylinder is provided with a tapered end 71, which is in contact with The plugging cap can make the plugging cap come out effectively.

[0017] In order to facilitate the reasonable recycling of the disassembled blocking cover, a box body is provided on the upper side of the lower horizontal plate corresponding to the position of the air rod.

[0018] The upper horizontal plate, the vertical plate and the lower horizontal plate form an unclosed square on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com