Hydraulic braking device and automobile with the same

A hydraulic braking and braking technology, applied in the direction of braking transmission, brakes, vehicle components, etc., can solve problems such as failure to achieve boosting effect, poor braking effect, traffic accidents, etc., and achieve sensitive braking response and structural design. Reasonable and easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

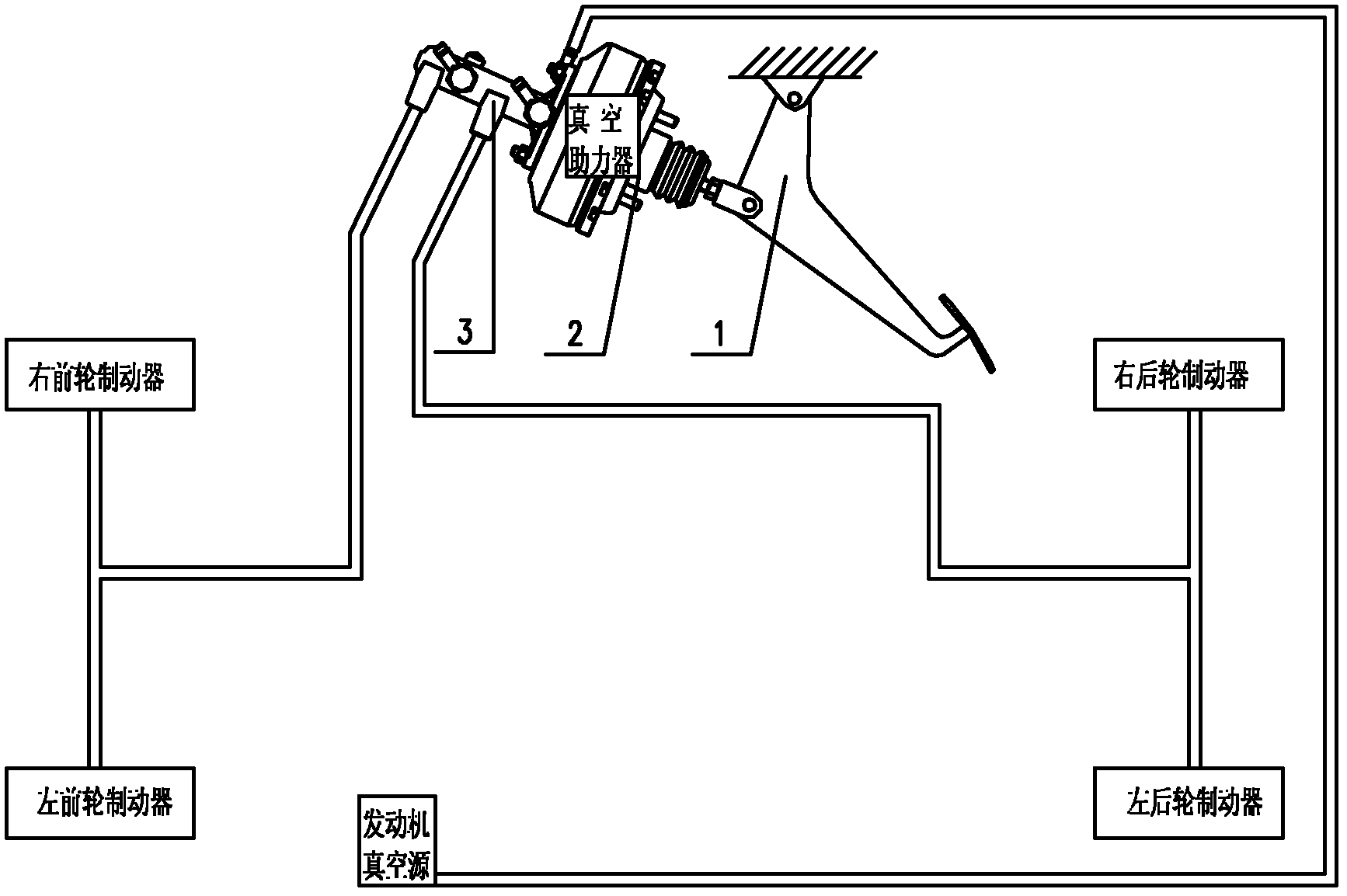

Embodiment 1

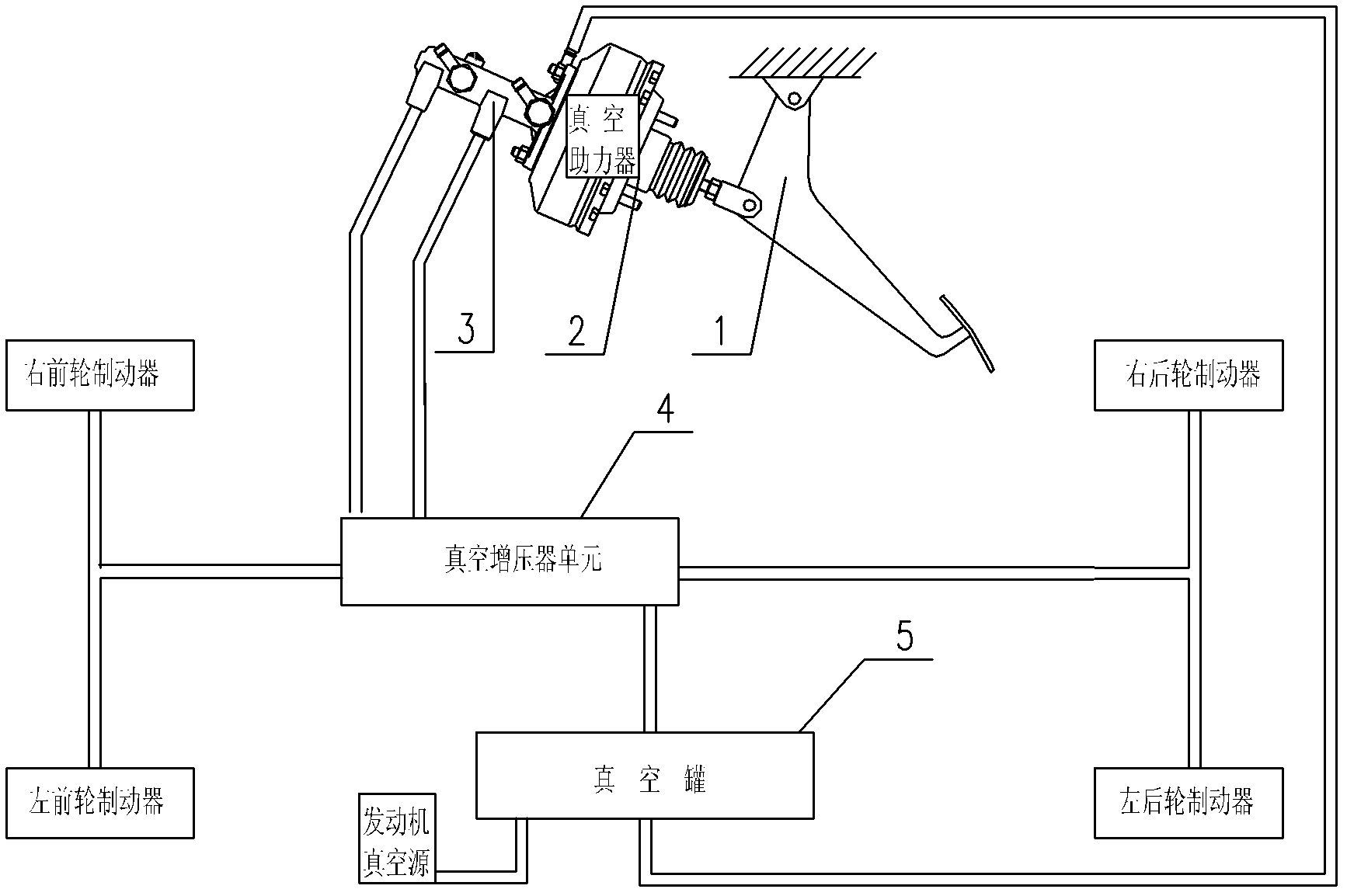

[0029] In the present embodiment, the vacuum booster unit 4 includes at least one vacuum booster, preferably one, which are connected in series through hydraulic pipelines to form a vacuum booster group; the vacuum booster group The vacuum booster at one end is connected to the brake master cylinder 3 through a hydraulic pipeline, and the vacuum booster at the other end of the vacuum booster group is respectively connected to the left front wheel brake, right front wheel brake, left rear wheel brake and right brake. The rear wheel brakes are connected, and each vacuum booster in the vacuum booster group is respectively connected with the vacuum tank 5 through a vacuum pipeline.

[0030] When the vacuum booster group includes a vacuum booster, the vacuum booster at one end of the vacuum booster group and the vacuum booster at the other end of the vacuum booster group are the same vacuum Supercharger.

[0031] Applying the hydraulic braking device described in this embodiment, ...

Embodiment 2

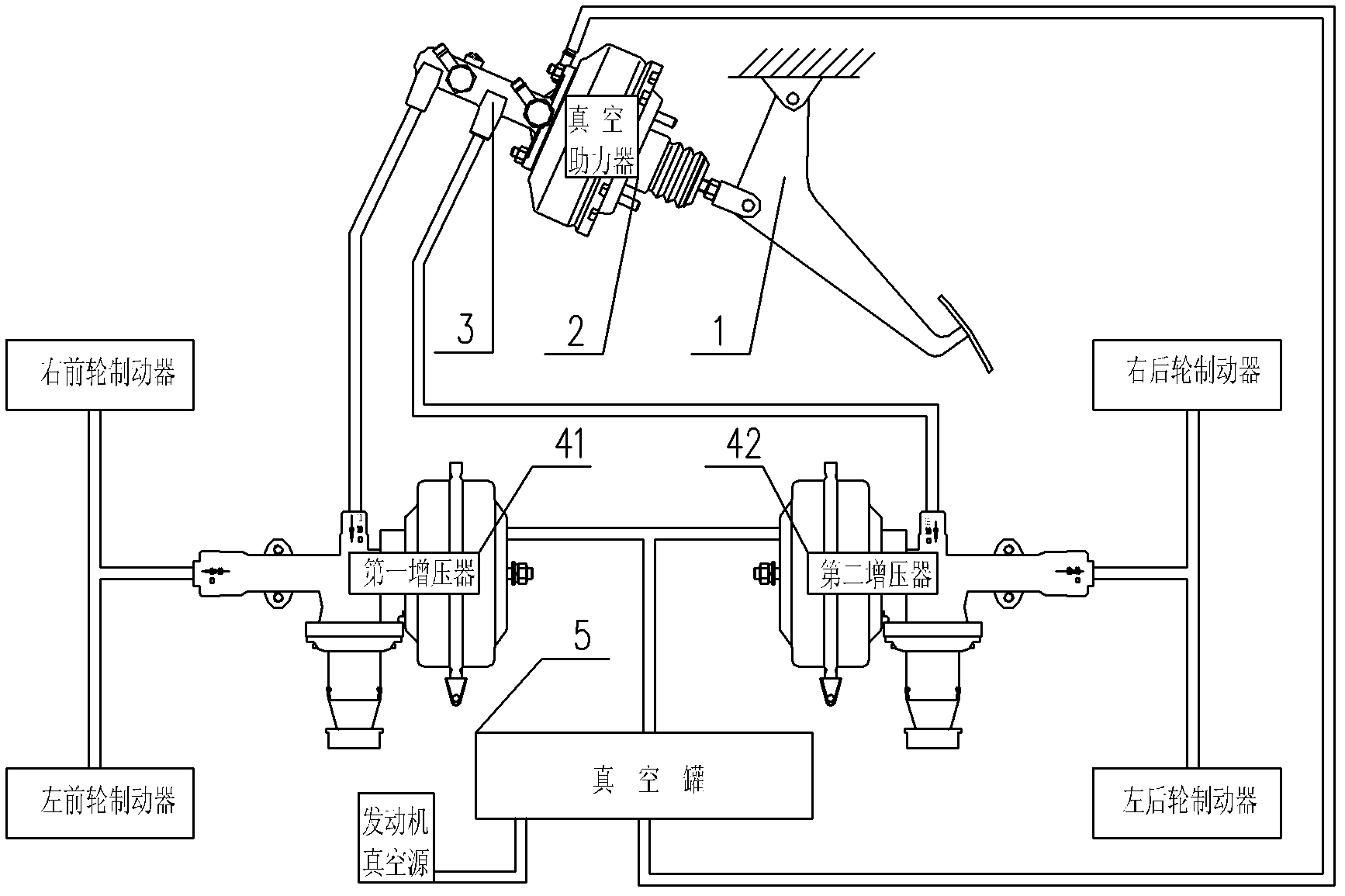

[0033]In this embodiment, the vacuum booster unit 4 includes at least one vacuum booster, preferably two, which are divided into two groups, and the vacuum boosters in each group are connected in series through hydraulic pipelines; wherein, The vacuum booster at one end of the first vacuum booster group is connected to the brake master cylinder 3 through a hydraulic pipeline, and the vacuum boosters at the other end of the first vacuum booster group are respectively connected to the left front wheel brake and the right front wheel brake. The vacuum booster at one end of the second vacuum booster group is connected to the brake master cylinder 3 through a hydraulic pipeline, and the vacuum booster at the other end of the second vacuum booster group is connected to the left rear wheel brake and the right rear wheel brake respectively. The rear wheel brakes are connected, and each vacuum booster in the first vacuum booster group and the second vacuum booster group is respectively ...

Embodiment 3

[0040] This embodiment is basically the same as Embodiment 2, the only difference is that the vacuum booster at one end of the first vacuum booster group is connected to the brake master cylinder 3 through a hydraulic pipeline, and the first vacuum booster group The vacuum booster at the other end is connected with the left front wheel brake and the right rear wheel brake respectively; the vacuum booster at one end of the second vacuum booster group is connected with the brake master cylinder 3 through a hydraulic pipeline, and the The vacuum boosters at the other end of the second vacuum booster group are respectively connected with the left rear wheel brake and the right front wheel brake.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com