Spectacle frame with spring hinge mechanism

A technology for spring hinges and spectacle frames, which is applied in the directions of glasses/goggles, optics, instruments, etc., can solve the problems of difficult assembly, high processing cost, large volume of the spring hinge mechanism, etc., and achieves easy assembly, simple processing, and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

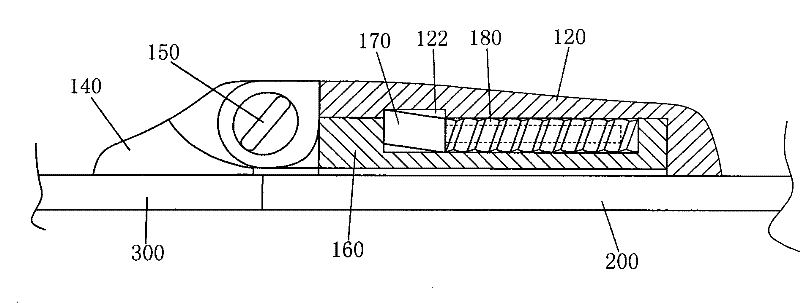

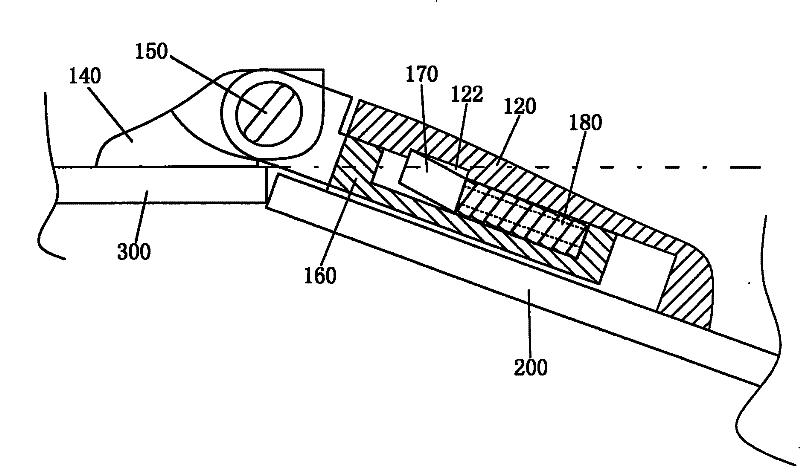

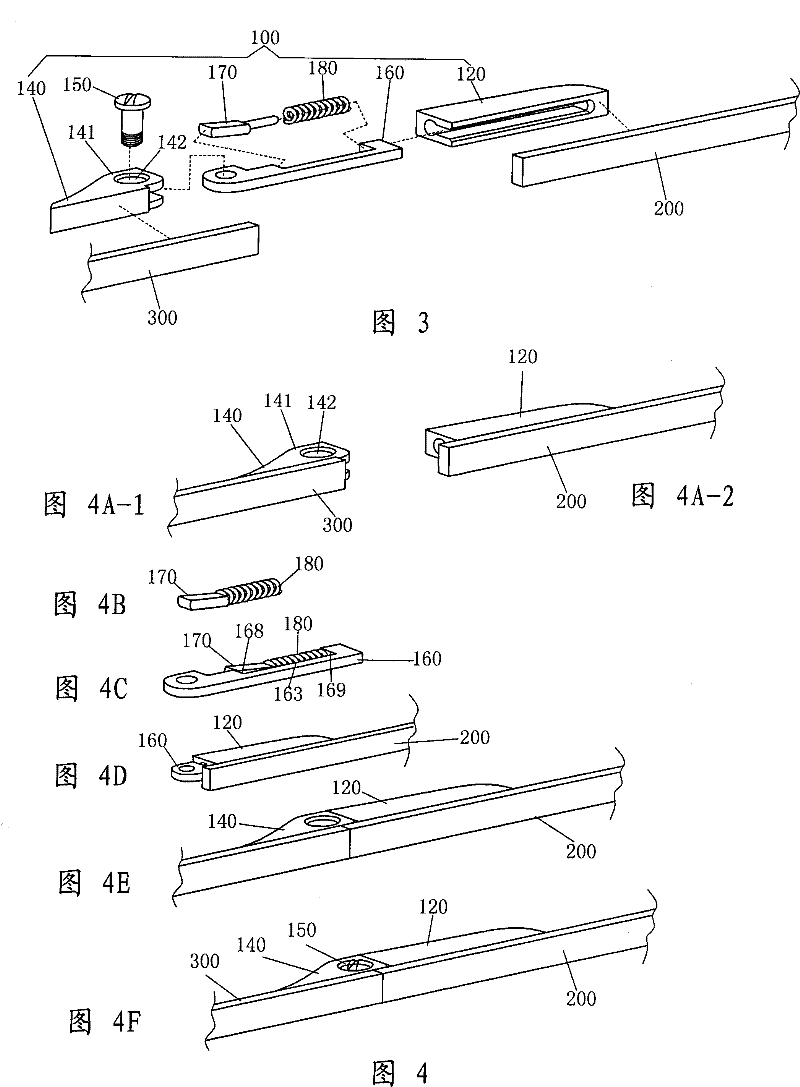

[0046] see Figure 8 and Figure 9 , the cross-section of the positioning guide member 170 is a parallelogram, and its three-dimensional shape is a parallelogram. 163, and inserted into the cavity 121 of the box body 120, the lower part of the front end 176 of the positioning guide member 170 withstands the inner wall 168 of the front end of the space 163, and the upper part of the front end 176 of the positioning guide member 170 withstands the The inner wall 123 at the front end of the notch 122 . The positioning guide member 170 can be made of stainless steel, cupronickel or manganese-phosphorus material.

Embodiment 2

[0048] see Figure 10 and Figure 11 , and the positioning guide member embodiment 1 is different in that the center of the tail 172 of the positioning guide member 170 is fixed with a guide shaft 171, and the outer diameter of the guide shaft 171 is adapted to the inner diameter of the spring 180; The length of the shaft 171 should meet the following requirements: when the spectacle arm 200 on the spectacle frame is in a natural state, the guide shaft 171 at the tail of the positioning guide member 170 that cooperates with the inner diameter of the spring 180 and the first joint assembly There is a certain gap in the inner wall 169 of the rear end of the space 163 of the main body 160; when the temples 200 on the spectacle frame are subjected to an external force, the temples 200 are opened outwards to a certain angle, and the spring 180 is not fully compressed to the end. The guide shaft 171 at the tail of the positioning guide member 170 first contacts the rear end inner w...

Embodiment 3

[0050] see Figure 12 , Figure 13 , Figure 5 and Figure 18 , in order to distinguish it from Embodiments 1 and 2 of the positioning guide member, the positioning guide member is represented by a reference numeral 190, the positioning guide member 190 is made of a material with good elasticity, and its front end is opened in a fork shape, so that the positioning The front end of the guide member 190 is bifurcated into upper and lower pages 194, 195, wherein the angle θ between the upper page 195 of the bifurcation and the vertical inner end surface 193 of the tail of the positioning guide member 190 is an obtuse angle, and the lower page of the bifurcation is an obtuse angle. The included angle θ1 between 194 and the vertical inner end surface 193 of the tail of the positioning guide member 190 is a right angle; After the box body 120 is inside the cavity 121, the tail end 192 of the positioning guide member 190 withstands one end of the spring 180, and the front end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com