car body

An automotive body, flange technology, applied in vehicle components, vehicle safety arrangements, superstructure sub-assemblies, etc., which can solve problems such as difficulty in complying with HIC limit values, increased beam resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

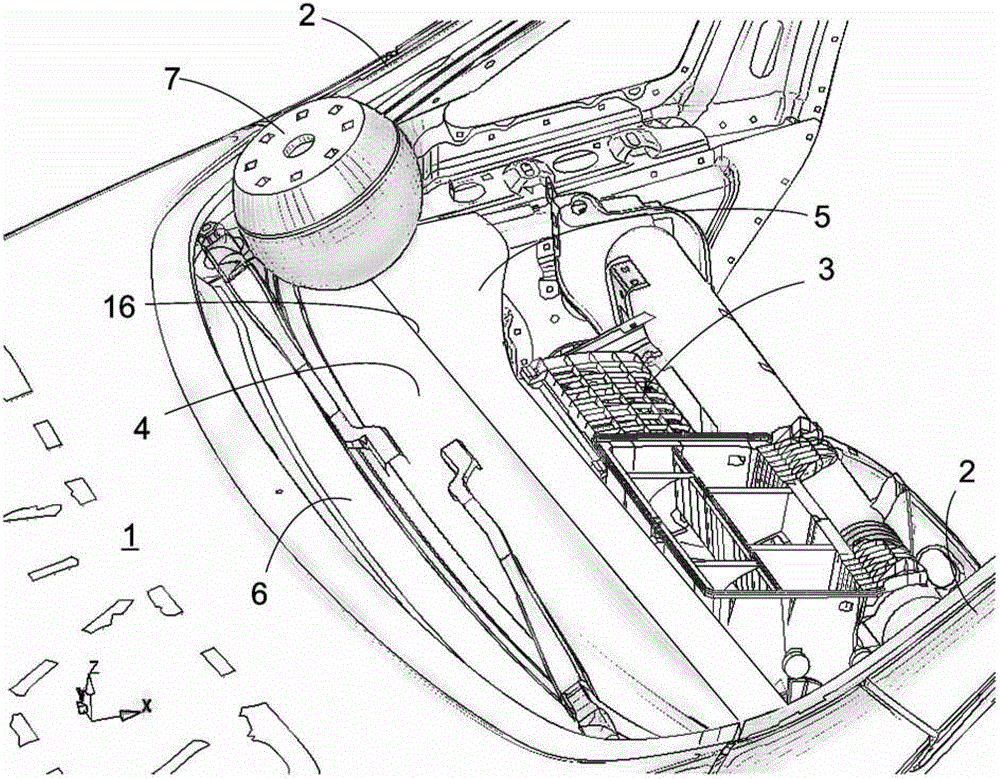

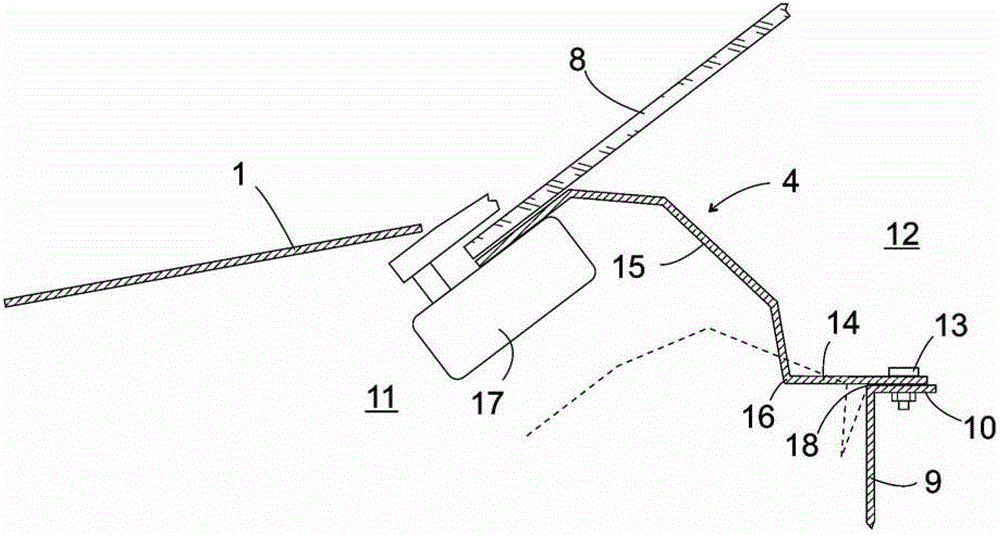

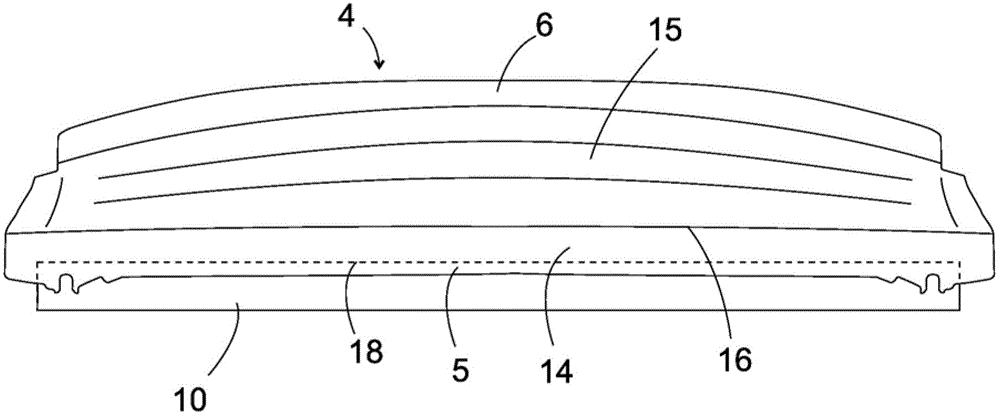

[0017] figure 1 A partial perspective view of an automobile body in which the invention may be used is shown. The rear area of the front panel 1 and the adjoining windshield opening flanked by the A-pillar 2 on which the windshield is mounted in the completed motor vehicle can be seen. Dashboard trim in figure 1 has been removed and not shown in order to be able to show the components 3 of the instrument panel arranged therebeneath and the cross member 4 formed from the single-layer blank, which are covered under the trim of the instrument panel in the completed vehicle. The rear flange 5 of the cross member 4 rests on the upper edge of a bulkhead, not visible in the figure, extending between the passenger compartment and the engine compartment. The front flange 6 of the oblique beam supports the front lower edge of the windshield.

[0018] The impactor 7 shown on the windshield cross member 4 represents a position, when the car collided with an adult (pedestrian of norma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com