Lifting pillar support

A technology of a column frame and a lifting mechanism, applied in the field of lifting mechanism, can solve the problems of instability, the rope is easy to break or fall off, easy to burn and explode, etc., and achieves the effect of convenient storage and transportation, improved application scope and efficiency, and easy deployment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

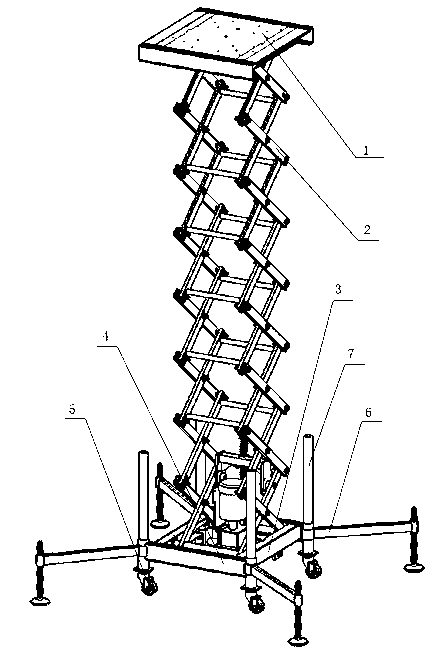

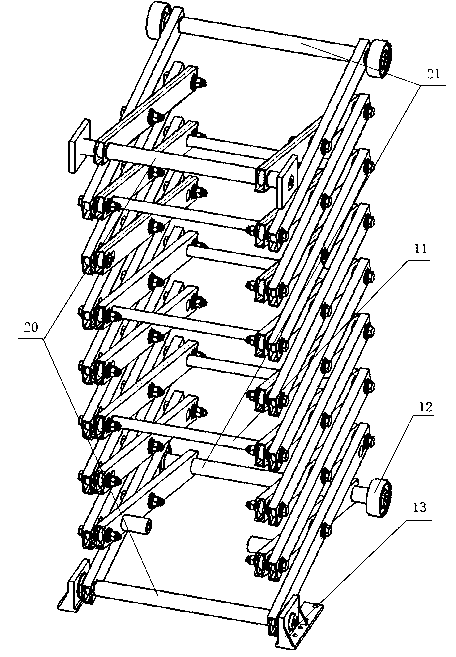

[0034] Such as Figure 1-5 As shown, a lifting column frame includes a base, a lifting mechanism and a driving mechanism. The lifting mechanism and the driving mechanism are installed on the base, and the driving mechanism drives the lifting mechanism to move up and down.

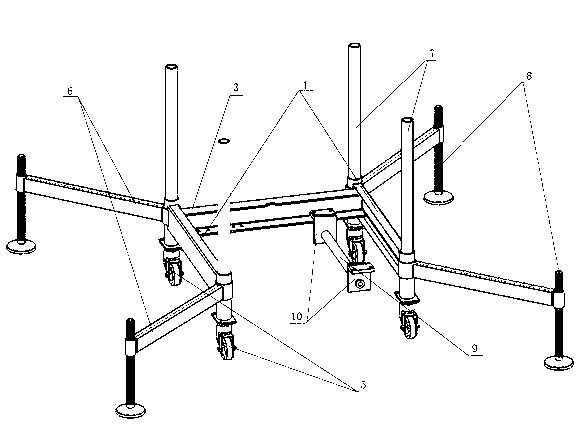

[0035] The drive mechanism includes a motor 14, a reducer 15, a screw 16 and a screw nut 17. The motor 14 drives the screw 16 through the reducer 15. When the screw 16 rotates, the screw nut 17 moves axially along the screw 16. The base includes a chassis, and the chassis is a quadrilateral structure composed of a main beam 3 and a cross beam 4, along one end of the main beam 3 there is a sliding groove for the movement of a roller or a slider; the base is also provided with a driving mechanism to support Components; the drive mechanism supporting component includes a support horizontal shaft 9 and a support hanging plate 10, the support horizontal axis 9 is connected to the support hanging plate 10, and th...

Embodiment 2

[0040] On the basis of Embodiment 1, a universal caster 5 is provided under the chassis, and the universal caster 5 is installed below the chassis.

[0041] The beneficial effect of this embodiment is that: a movable lifting column frame is realized, which facilitates the movement and positioning of the column frame.

Embodiment 3

[0043] On the basis of Embodiment 2, a column 7 is also provided on the base, and the column 7 is installed at the four corners of the chassis to form a four-corner column. A connecting arm 6 is set on each column 7, and the connecting arm 6 can surround The vertical rod 7 rotates, and the end of the connecting arm 6 is connected with a supporting foot 8, and the supporting foot 8 is adjusted to the distance from the ground by a screw mandrel.

[0044] The beneficial effect of this embodiment is that: the extended support composed of the connecting arm 6 and the supporting foot 8 can easily adjust the balance of the whole mechanism, can be installed on an uneven ground environment, and has higher wind resistance, improving the mechanism stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com