Highland road gradation crushed gravel material design method

A technology of crushed stone material and design method, applied in the field of materials, can solve the problems of serious segregation of aggregates and easy segregation in construction, and achieve the effect of reducing segregation in construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention is described in further detail below in conjunction with accompanying drawing:

[0046] In the gradation study, gravel with a nominal particle size of 31.5 mm was used for gradation design. The specific design is as follows:

[0047] (1) Measure the gross bulk density of the blended coarse aggregates (the part larger than 4.75mm, namely: 5~10, 10~20, 20~31.5mm).

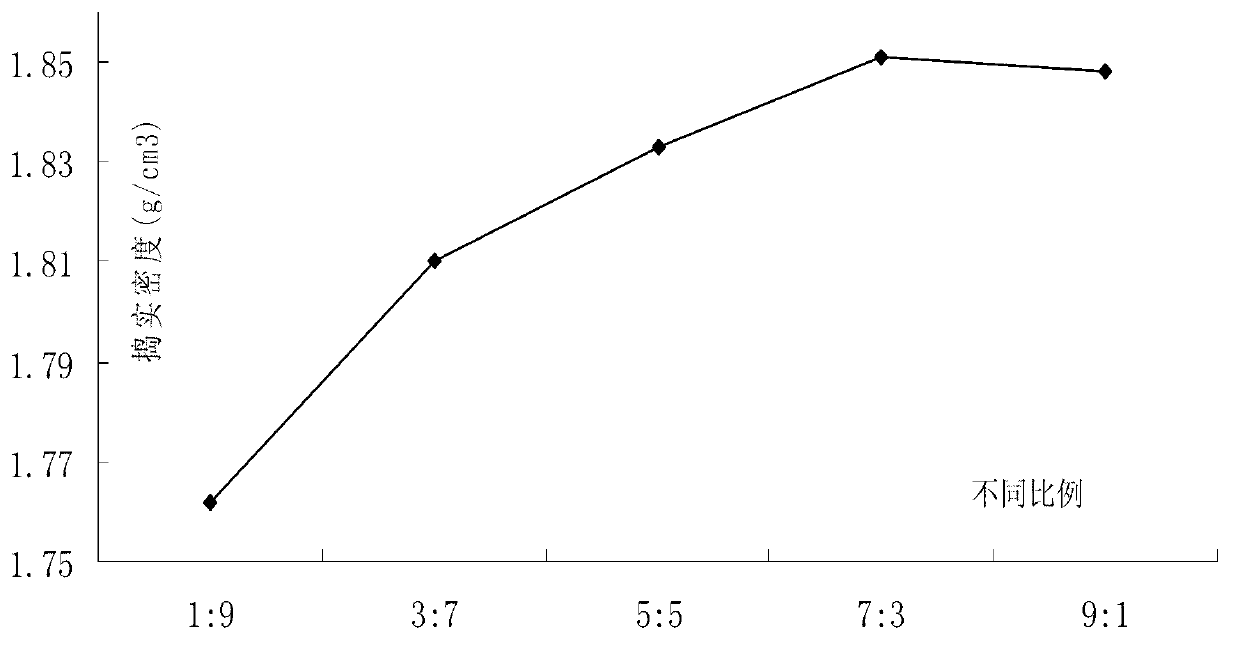

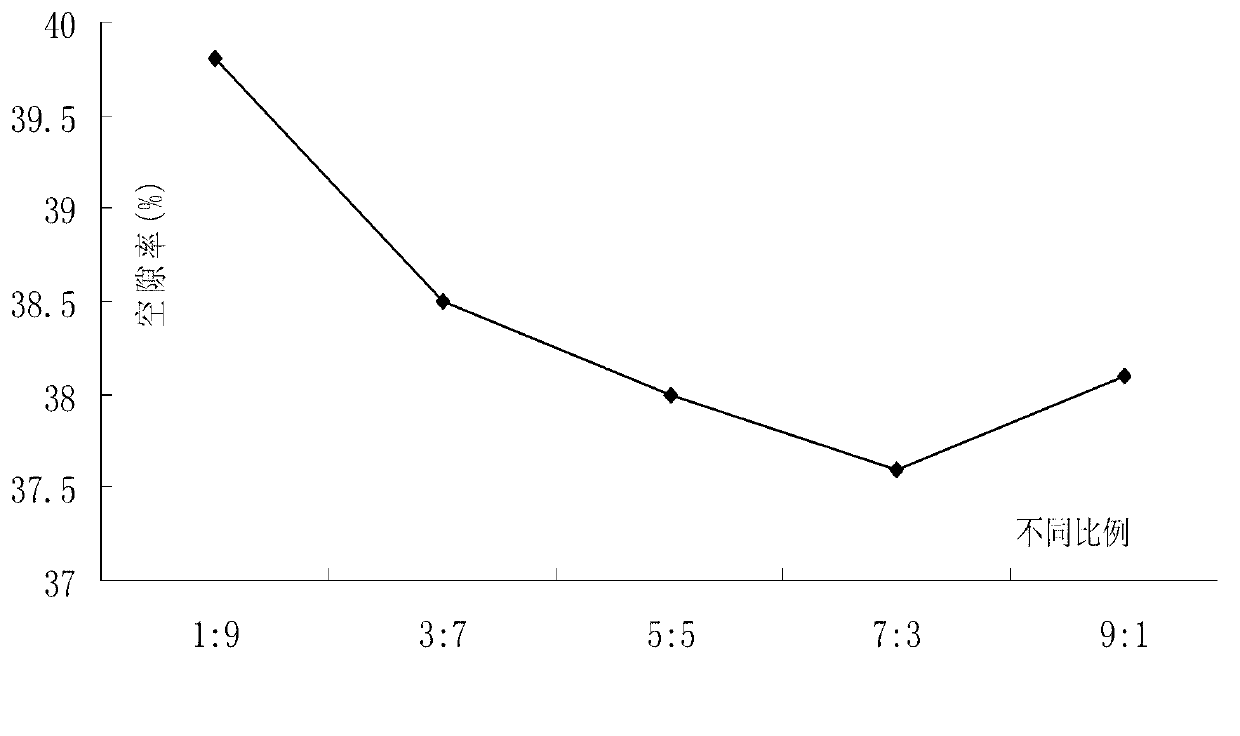

[0048](2) With the same total mass and different proportions, the aggregates of 20-31.5 and 10-20 were used for filling tests, and the blending ratio of these two grades of aggregates at the maximum packing density was measured.

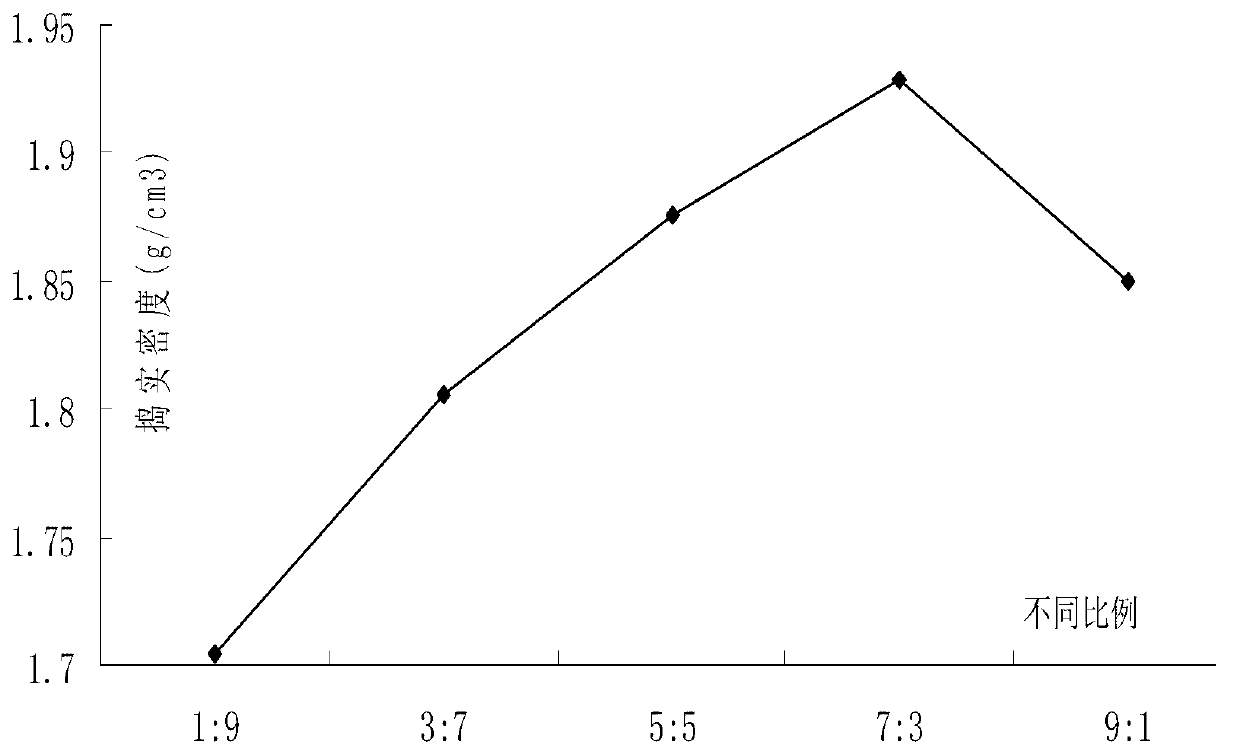

[0049] (3) With the blending ratio of the two grades of aggregates determined above, the same method is used to study the blending ratio of each grade of aggregates to obtain the maximum packing density.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nominal particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com