Foamed rubber seal strip

A sponge rubber and sealing strip technology, applied in the field of rubber production, can solve the problems of endangering the health of employees, polluting the environment, carcinogenicity, etc., and achieve the effect of ensuring health and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

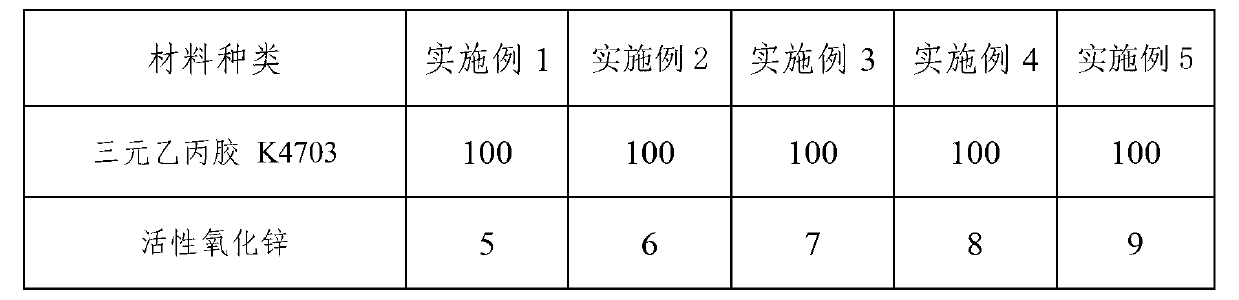

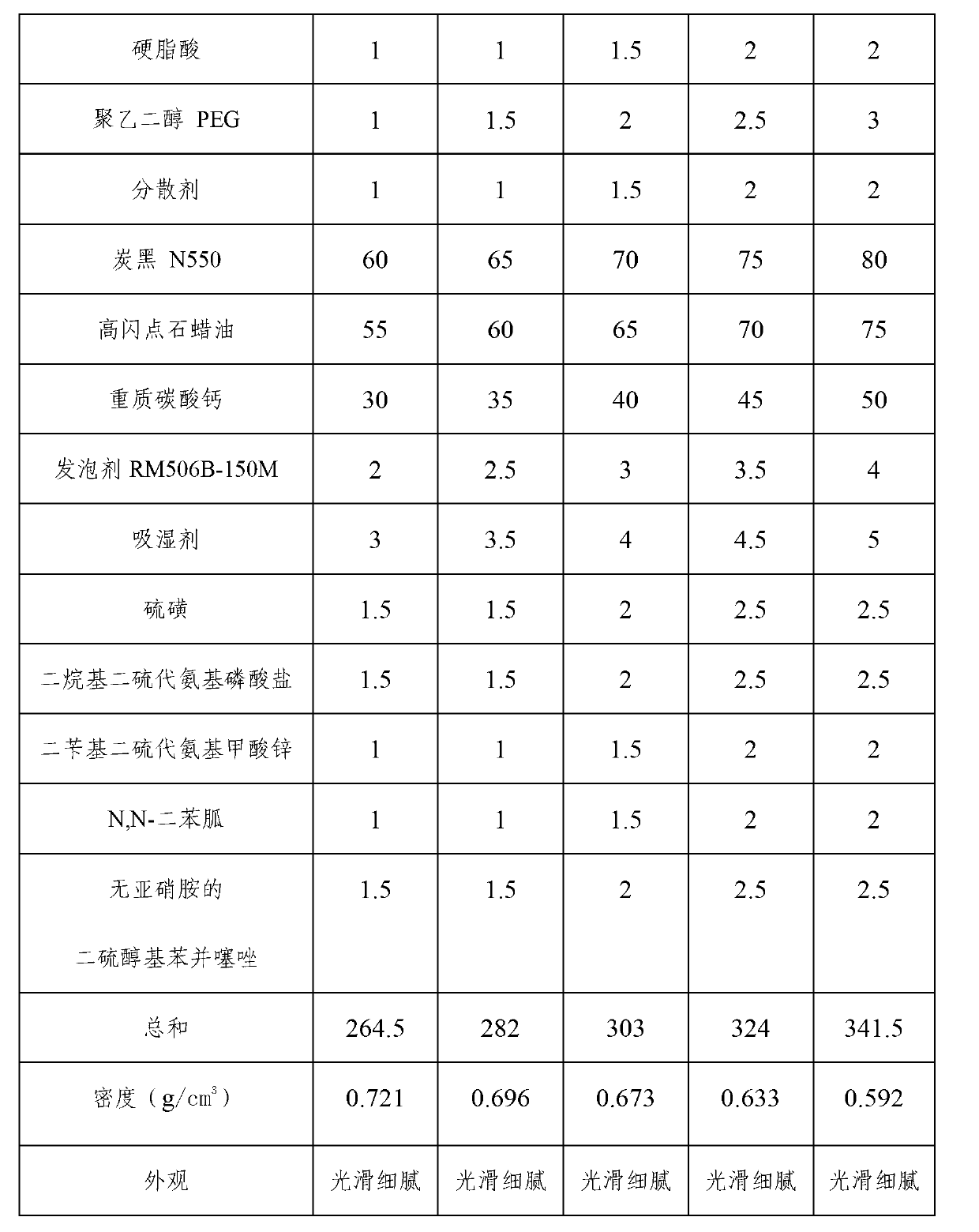

[0020] It should be noted that the parts in the present invention are all parts by mass.

[0021] The embodiment of the present invention provides a sponge rubber sealing strip, which comprises the following raw materials in parts by mass: 100 parts of EPDM rubber, 5-9 parts of active zinc oxide, 1-2 parts of stearic acid, 60-80 parts of carbon black, 55-75 parts of high flash point paraffin oil, 30-50 parts of heavy calcium carbonate, 3-5 parts of hygroscopic agent, 1.5-2.5 parts of dialkyl dithioamidate and dibenzyl 1-2 parts of zinc dithiocarbamate.

[0022] The dialkyl dithioamidate ZAT-60 and zinc dibenzyl dithiocarbamate ZBEC-75 are used as vulcanization accelerators for rubber crosslinking, which play the role of main accelerators and will not It produces amine nitrite, which is an environmentally friendly vulcanization system, making sponge rubber a non-toxic and environmentally friendly material.

[0023] Preferably, the sponge rubber sealing strip of the present in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com