Coated part and preparation method thereof

A technology for coated parts and coating layers, applied in the field of two-color coated parts and its preparation, can solve the problems of inaccurate positioning, poor pattern fineness, cumbersome process, etc., and achieve rich color combinations, high accuracy, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

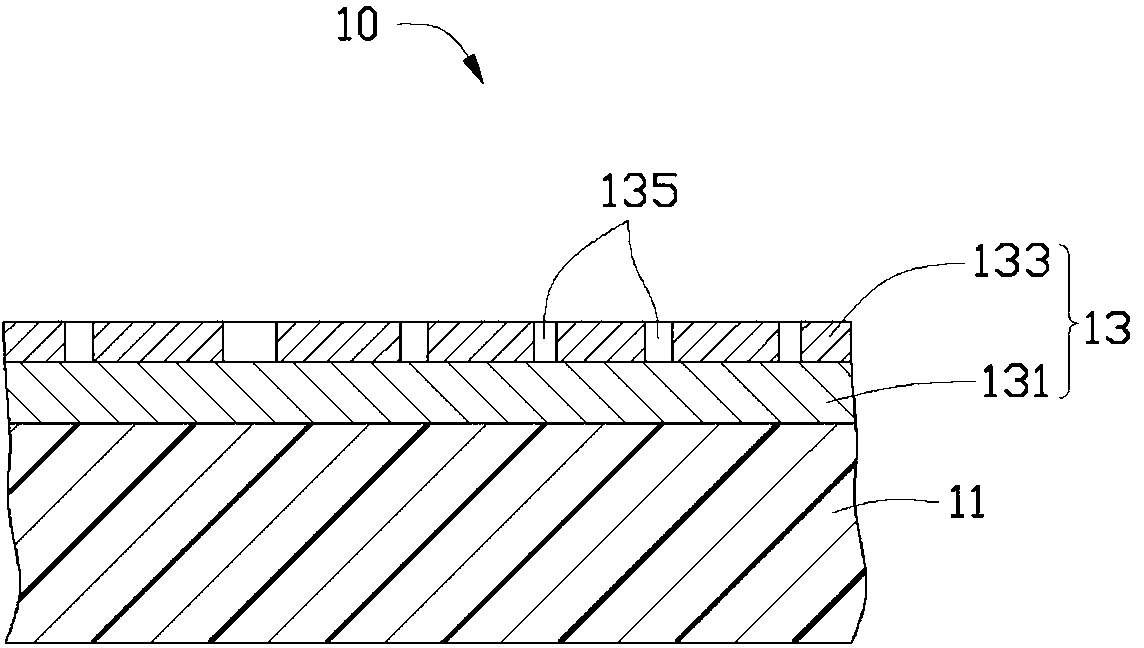

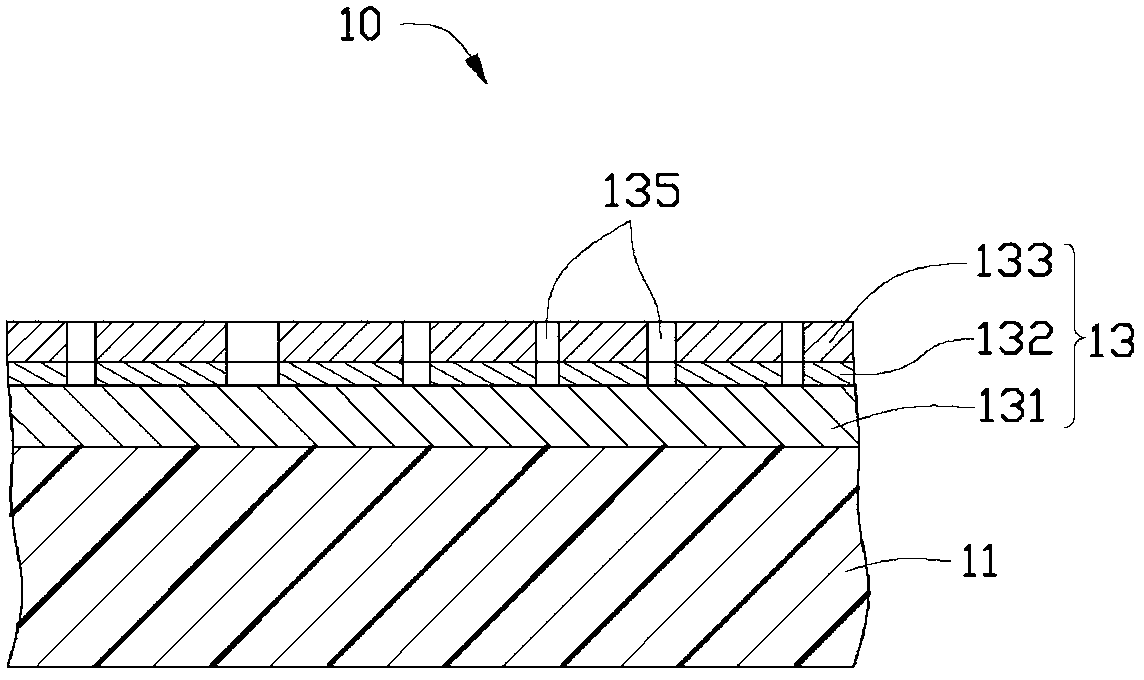

[0026] The preparation method of the above-mentioned coating member 10 mainly includes forming the first color layer 131 on the surface of the substrate 11 by vacuum coating and then forming the second color layer 133. The first color layer 131 and the second color layer 133 have different The color of the base material 11 is shielded and protected with a shielding object, so that the partial area of the second color layer 133 is shielded; the substrate 11 treated with shielding is immersed in the stripping solution, so that the second color layer 133 is not shielded The part is removed to form an opening 135, so that the underlying first color layer 131 is partially exposed through the opening 135; the mask is removed, so that the surface of the film-coating member 10 presents two different colors.

[0027] The vacuum coating method may be a magnetron sputtering method.

[0028] Forming the first color layer 131 is under the condition of magnetron sputtering, with chromium ...

Embodiment

[0038] 1. Ultrasonic cleaning

[0039] The substrate 11 made of stainless steel (model 316L) was put into an ethanol solution for ultrasonic cleaning to remove impurities and oil stains on the surface of the substrate 11, and dried for later use after cleaning.

[0040] 2. Coating

[0041] Magnetron sputtering equipment (produced by Shenzhen Nanfang Innovation Vacuum Technology Co., Ltd., model SM-1100H. The magnetron sputtering equipment includes a vacuum chamber, a turntable, a magnetron target and a bias power supply. The magnetron target is a target structure , including a pair of chromium targets and a pair of titanium targets, a certain distance is formed between each pair of targets. The substrate is fixed on the turntable, and the turntable drives the substrate to pass between each pair of chromium targets when the turntable rotates.

[0042] Depositing the first color layer 131: adjust the temperature in the vacuum chamber to 150°C, feed argon gas into the vacuum cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com