Cast support seat

A technology of support and hinged seat, which is applied in the direction of earth mover/excavator, construction, etc., can solve the problems of high manufacturing cost and easy failure, and achieve the effect of ensuring quality, strengthening strength, and preventing support damage and failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

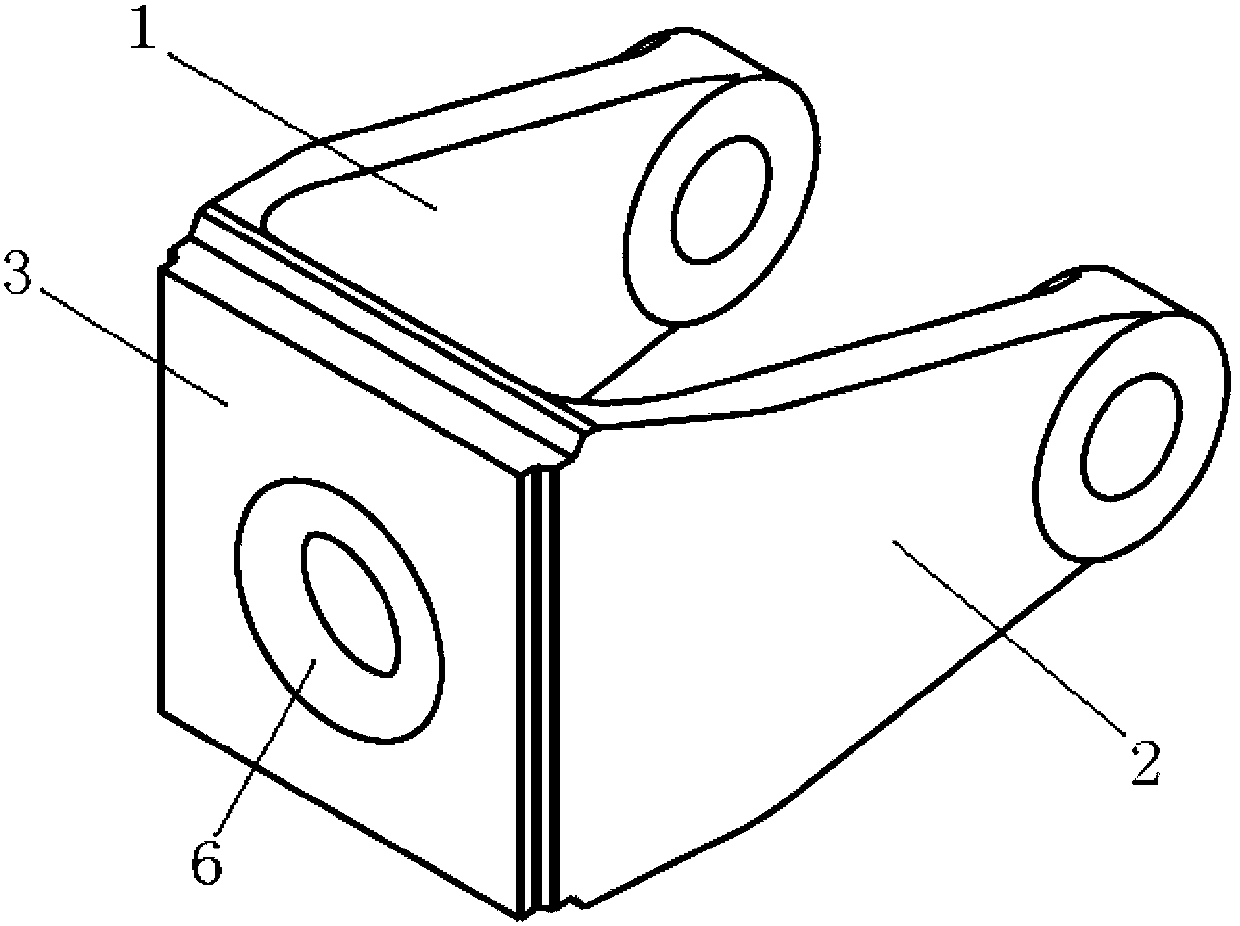

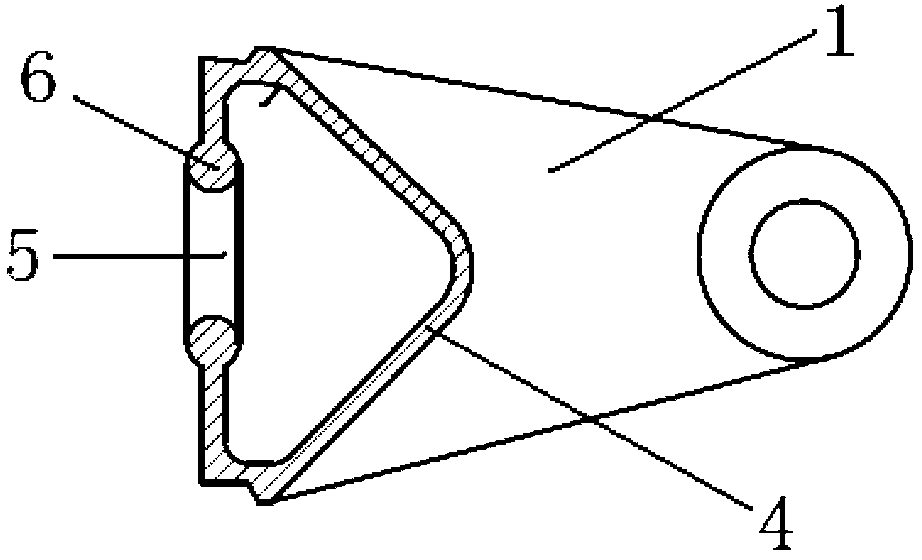

[0019] like figure 1 figure 2 As shown, the casting support in this embodiment is formed by casting at one time, which includes a left hinged seat 1 and a right hinged seat 2, and the bottoms of the left hinged seat 1 and the right hinged seat 2 are connected by a square middle partition 3, There is a V-shaped reinforcing plate 4 between the left hinged seat 1 and the right hinged seat 2, the two ends of the V-shaped reinforced plate are respectively connected with the left hinged seat 1 and the right hinged seat 2, and the two sides are connected with the middle partition, V-shaped Reinforcement plate 4, left hinged seat 1, right hinged seat 2, and middle partition 3 form a box-shaped structure, on which middle partition 3 is provided with a sand cleaning port 5, and on the edge of the sand cleaning port 5 there is a surrounding sand cleaning port. The closed annular rib 6 of the mouth, the cross section of the annular rib 6 is roughly circular, its diameter is greater than...

Embodiment 2

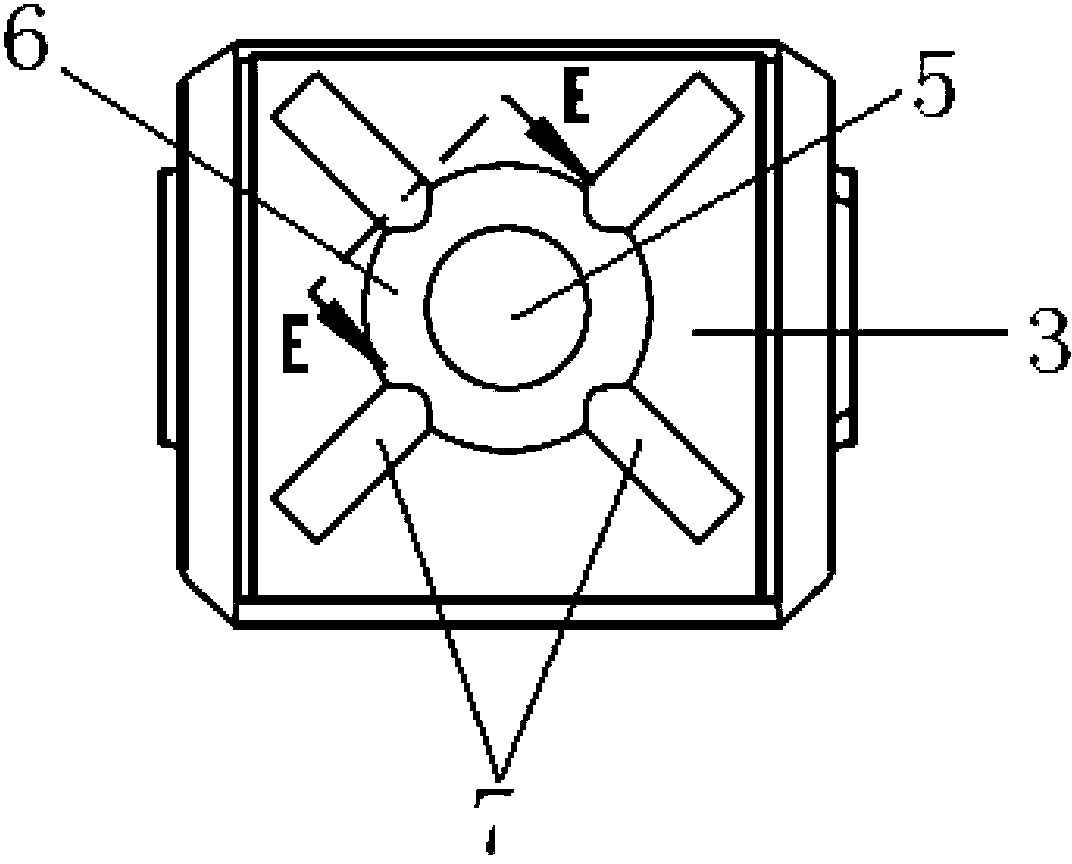

[0022] Compared with Embodiment 1, this embodiment differs in that an anti-torsion rib 7 is also provided on the outside of the middle partition, such as image 3 As shown, the number of torsion ribs 7 is four, one end of which points to the center end of the middle part of the middle partition 3, the center end is connected with the annular rib 6, and the other end of the torsion rib 7 points to the middle partition 3 A corner of , which is consistent with the diagonal direction of the middle partition 3; as Figure 4 As shown, the cross section of the torsion rib 7 is semicircular, and the cross section of the torsion rib 3 can also be semi-elliptic, etc.; . In this embodiment, the anti-torsion ribs 7 can be arranged on the outside of the middle partition 3, or on the inside of the middle partition 3, or both inside and outside of the middle partition 3, and the anti-torsion ribs 7 on the inside and outside sides The twisted ribs are symmetrical about both sides of the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com