Double-field variable-focus three-dimensional measurement system

A technology of three-dimensional measurement and variable focus, which is applied in the direction of measuring devices, instruments, and optical devices, etc., can solve the problem that it is difficult to take into account the imaging accuracy and imaging field of view of a single system, and achieve dynamic three-dimensional visual imaging with continuous variable angles, improve Accuracy, effects of avoiding time lag and errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

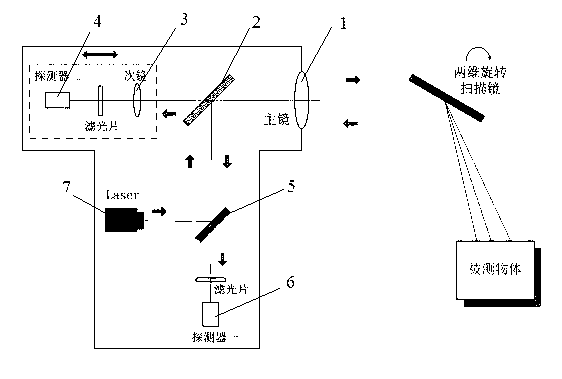

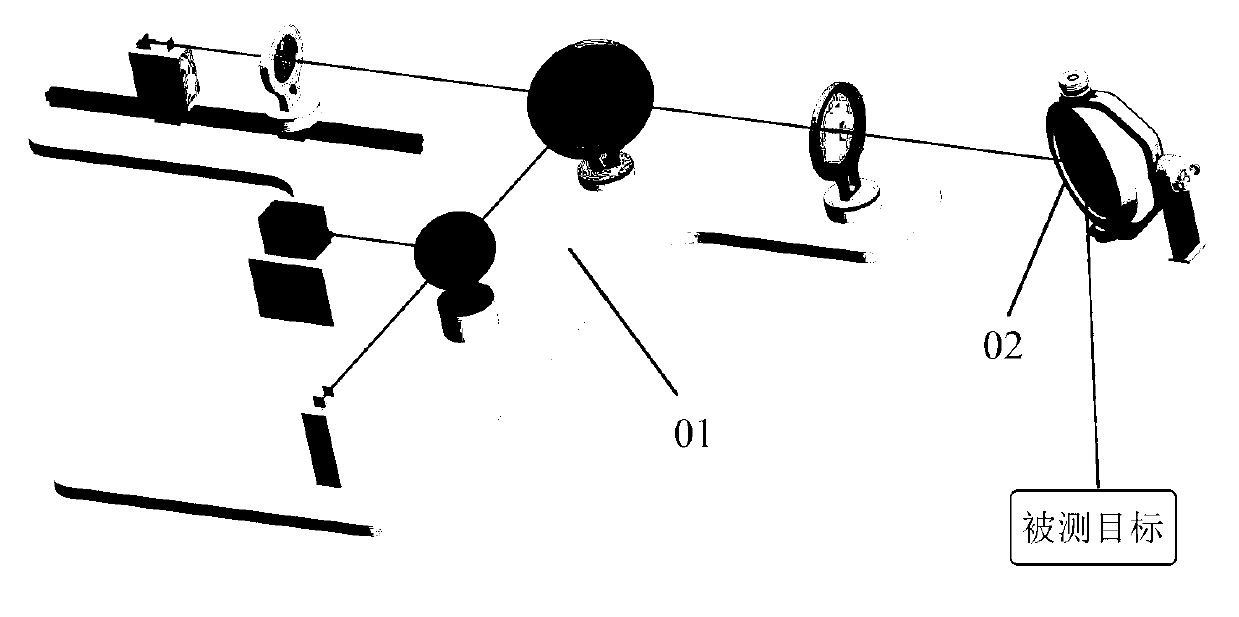

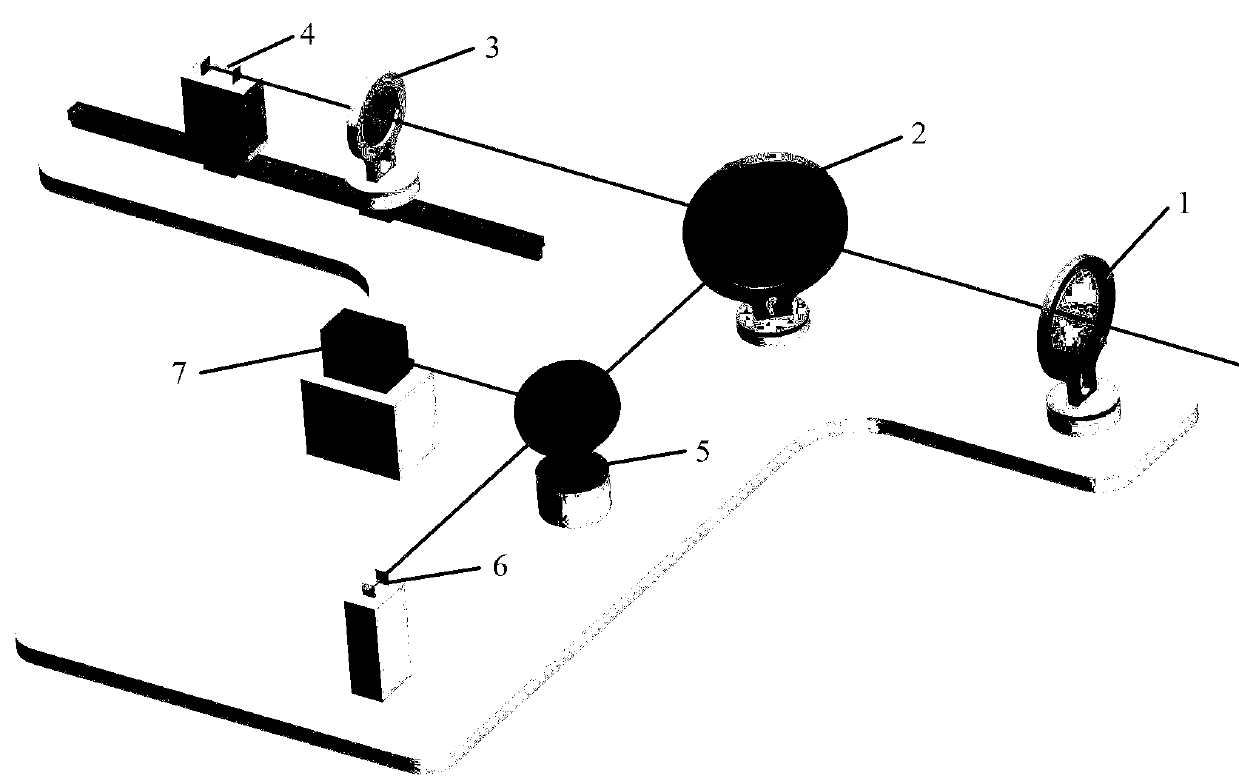

[0038] Example 1: see first Figure 1-Figure 5 shown. figure 1 It is a scheme diagram of the dual-view zoom three-dimensional measurement system of the present invention. figure 2 It is a three-dimensional rendering of the dual-field variable-focus three-dimensional measuring device of the present invention. image 3 It is a three-dimensional rendering of the primary and secondary mirror imaging measurement system of the present invention. Figure 4 It is a three-dimensional rendering of the two-dimensional tracking mirror device of the present invention. Figure 5 It is a block diagram of the adaptive control system of the present invention. Depend on Figure 1-Figure 5 It can be seen that the dual-field zoom three-dimensional measurement system of the present invention is composed of a primary and secondary mirror imaging measurement system 01, a two-dimensional tracking and rotating mirror device 02, and an adaptive control system. in:

[0039] The primary and secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com