Method for authenticating steam output and consumption in iron and steel enterprises

A technology of production and consumption, applied in measuring devices, liquid/fluid solids measurement, instruments, etc., can solve the problems of low accuracy of steam measuring instruments, and the difference between total production and total consumption is far

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

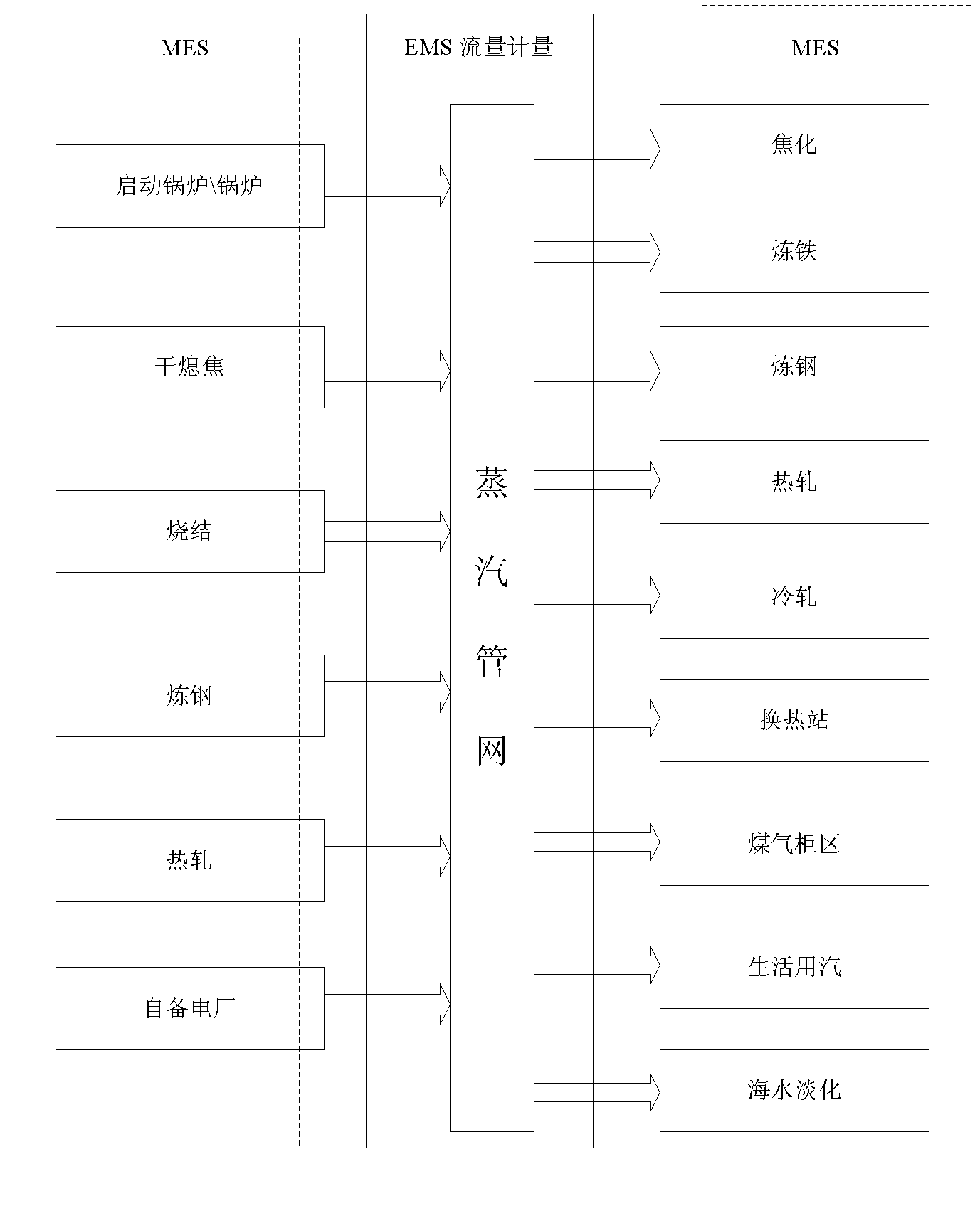

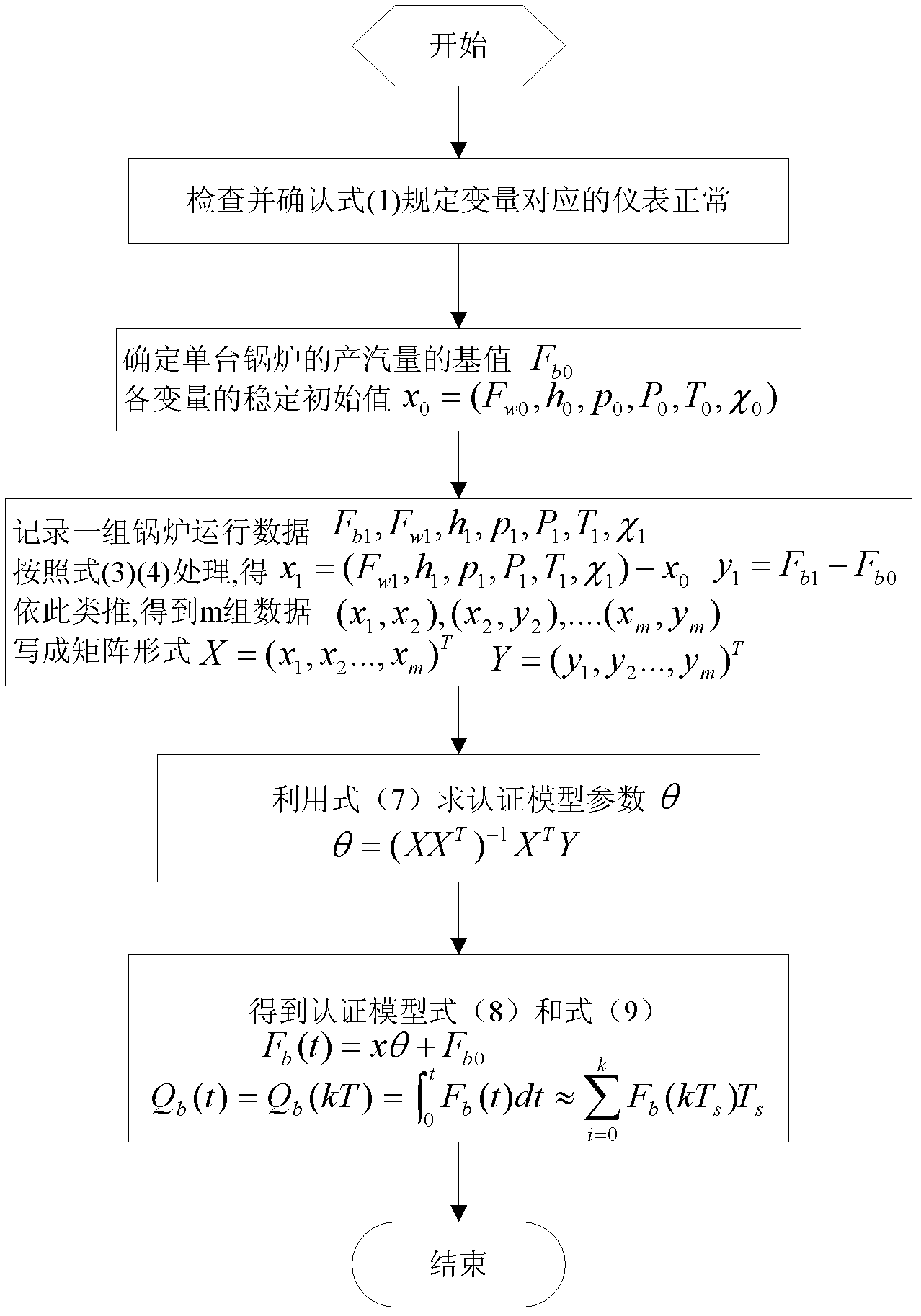

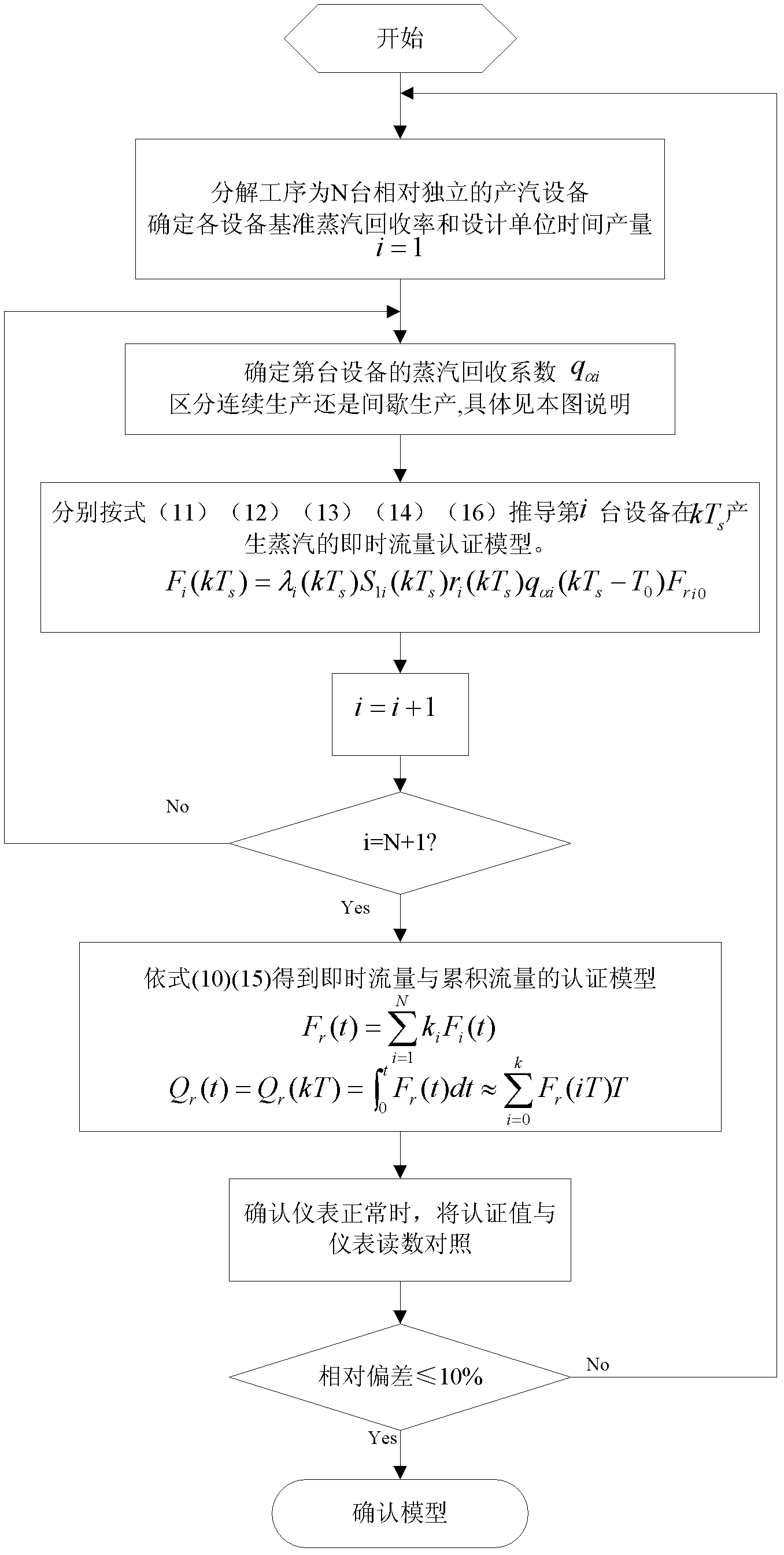

[0074] Such as figure 1 As shown, the processes related to the steam pipe network and the direction of steam in a typical iron and steel enterprise have been marked in the figure. After the realization of production informatization, the monitoring and metering of the steam pipe network belong to the EMS system, which mainly monitors the temperature, pressure, and flow of the inlet and outlet of the pipe network; at the same time, it measures the flow of each production steam process into the pipe network and the steam consumption of the steam process. traffic. Inside each process, the automatic control system performs the tasks of detection, adjustment and monitoring of production state variables, and the information of this part is integrated into the MES system. Many iron and steel enterprises EMS and MES have mutual access functions. Thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com