On-line monitoring and early-warning method for operating state of gearbox

A gearbox and gear technology, which is applied in the field of gearboxes, can solve the problems that the timeliness of information cannot be guaranteed, and the running status of the gearbox cannot be monitored timely and accurately.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

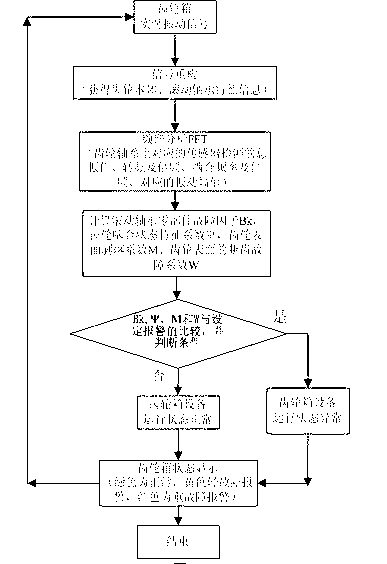

[0042] The online monitoring method of the gear box equipment running state of the present invention comprises a gear box, a rolling bearing and a vibration sensor arranged on the bearing seat for monitoring the vibration signal of the rolling bearing, such as figure 1 As shown, the method includes the following steps:

[0043] Step 1, collecting the output signal Y of the vibration sensor i , for the original signal Y i Perform frequency spectrum analysis, and obtain the characteristic information of the gear body and rolling bearing through signal reconstruction, and extract the total vibration value, rotation frequency and frequency multiplication, meshing frequency and multiplication frequency, and corresponding vibration amplitude detected by the corresponding sensor on the gear shafting;

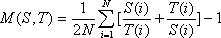

[0044] Step 2, the bearing fault shows that there is an impact on the unusual vibration level value, and the relationship between the impact rate and the vibration spectrum of each co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com