Method for predicting corrosion life of transmission line hardware in industrial area

A transmission line and life prediction technology, applied in the field of electric power engineering, achieves the effects of high accuracy, safety assurance, and fast time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

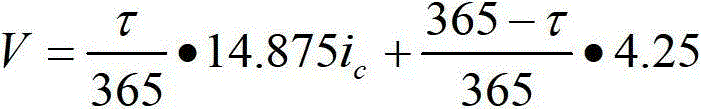

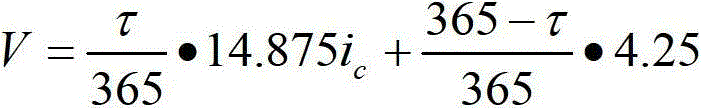

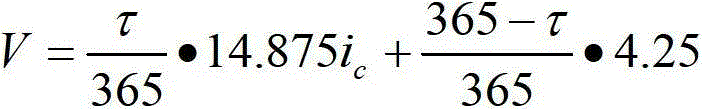

Image

Examples

Embodiment 1

[0021] (1) Take samples from the fittings on the transmission line of the industrial area to be predicted or from the spare fittings that have been shipped for more than 8 months and have a stable galvanized layer but no red rust, and use a wire cutting machine to cut them from the sample fittings The area of galvanized layer on one side of one piece shall not be less than 1cm 2 1cm×1cm square sample pieces;

[0022] (2) A copper wire is connected to the back side of the galvanized side of the sample piece cut out in step (1), and epoxy resin is used to connect the copper wire together with the side of the sample piece connected to the copper wire encapsulation. The copper wire is connected to the other end of one end of the sample piece as a connecting terminal protruding from the epoxy resin and made into a working electrode for electrochemical testing. After the epoxy resin is cured, first use deionized water to clean the galvanized surface of the sample piece, then use...

Embodiment 2

[0035] Steps (1) to (3) are the same as in Example 1;

[0036] (4) Take analytically pure NaHSO 3 55 grams, 1000 grams of deionized water. The analytically pure NaHSO 3 Add the simulated acid rain solution to the deionized water taken gradually, track and measure the pH value of the configured simulated acid rain solution with a pH acidity meter, and determine that the pH value of the simulated acid rain solution is the same as that obtained in the above step (3) for at least 10 years. The annual mean value of acid rain pH x NaHSO at the same time 3 Concentration. If the difference between the pH value of the simulated acid rain solution and the local pH value x of at least the last 10 years obtained in step (3) is less than 0.03, the NaHSO 3 Add NaOH solution dropwise to the solution until the pH value of the simulated acid rain solution is exactly the same as the local acid rain pH average value x obtained in step (3) for at least the past 10 years;

[0037] Steps (5) t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com