Centering attachment of a compressor housing cover

A turbo compressor and casing technology, which is applied in the field of centering and fixing the compressor casing cover, can solve the problems of gap reduction and radial gap that cannot be reduced arbitrarily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

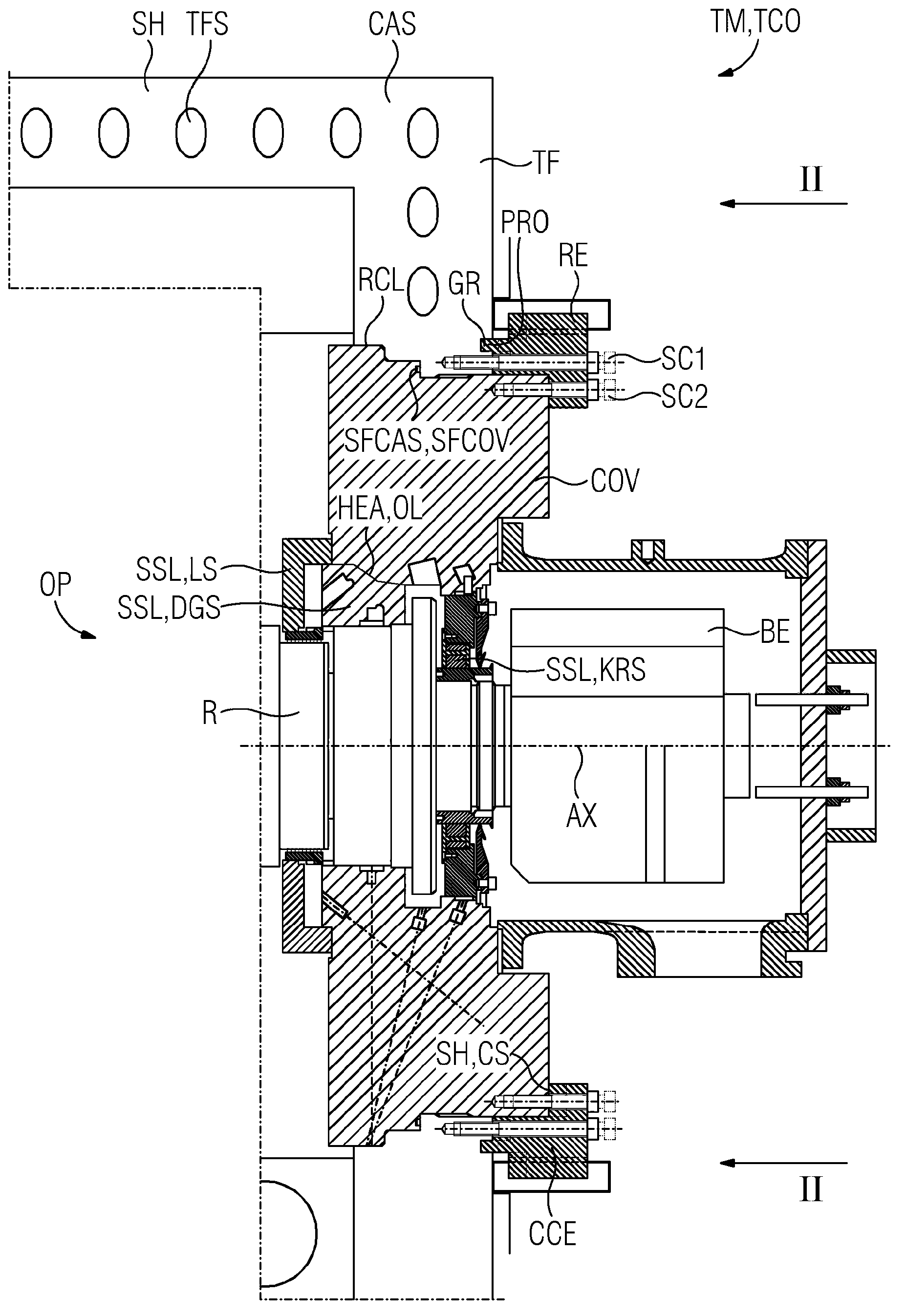

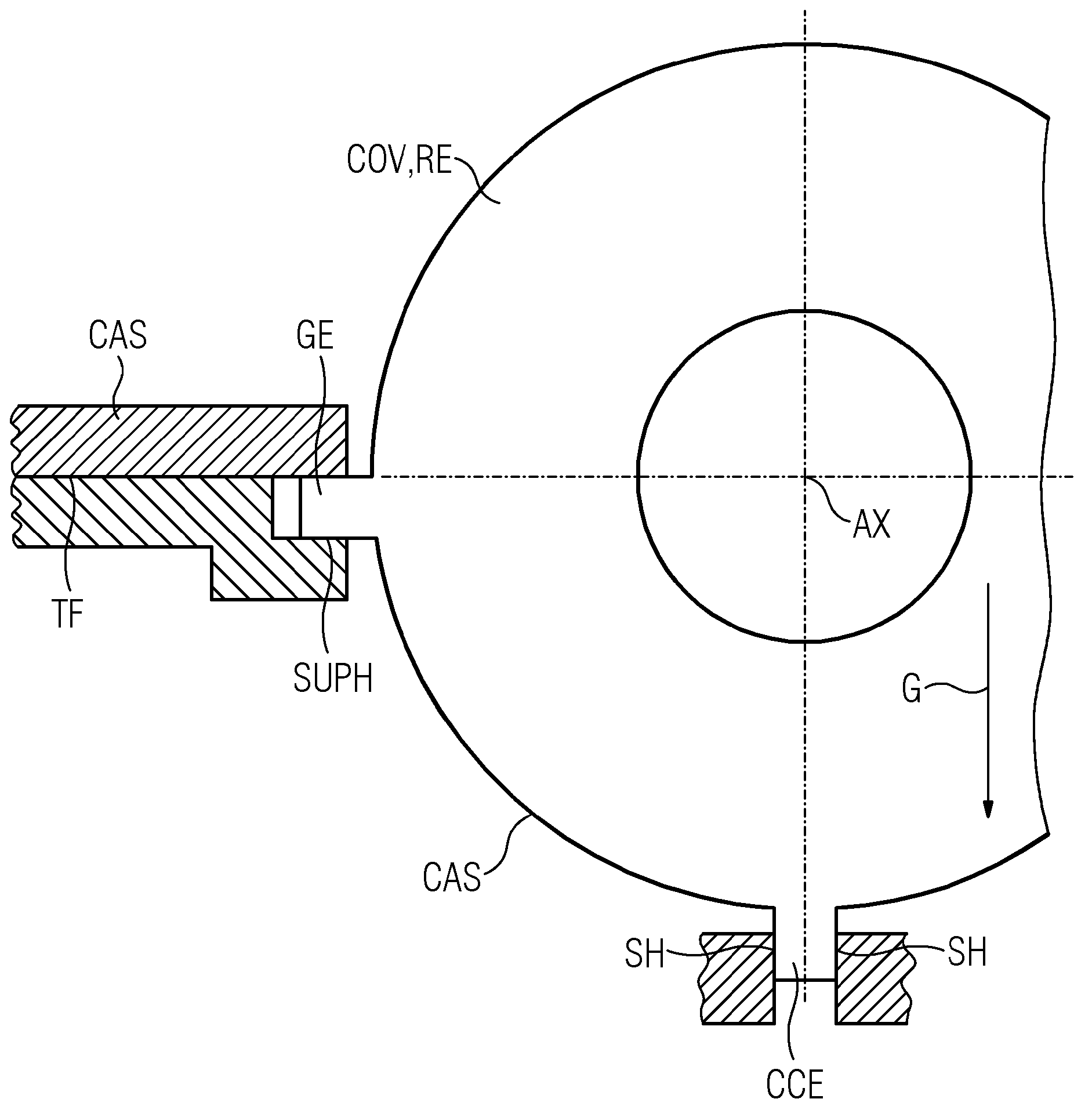

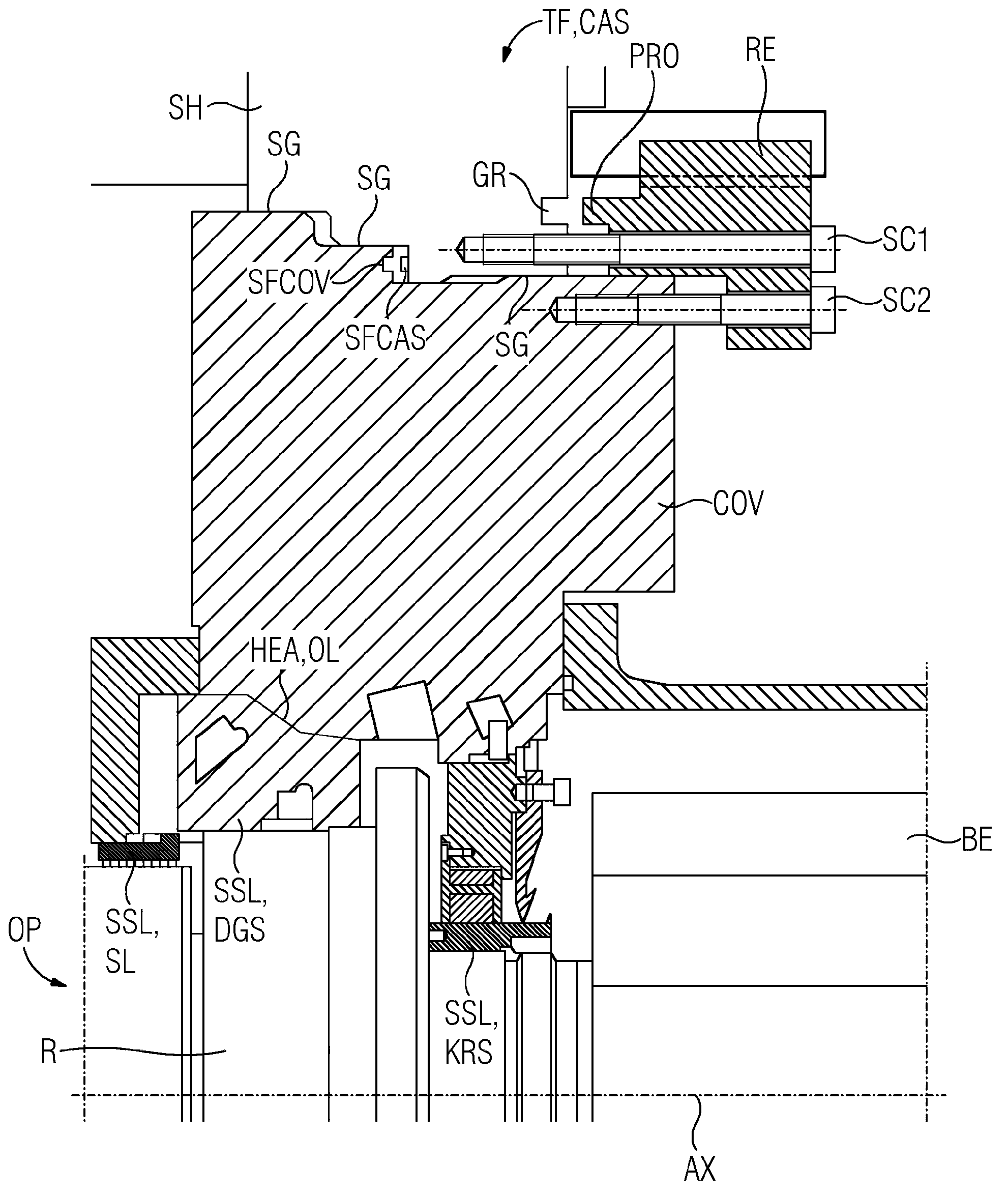

[0022] figure 1 Shown is a turbomachine TM, ie a turbocompressor TCO with a housing CAS or a turbocompressor housing according to the invention. The casing CAS extends along the longitudinal axis AX and has a horizontal joint TF held together by means of joint screws TFS. The housing CAS can be subdivided into a housing part SH and a cover COV. The cover SH is provided with a horizontal joint TF. The cover COV is undivided and has a substantially planar extension perpendicular to the longitudinal axis AX, which has a substantially circular outer contour. In the region around the longitudinal axis of the housing part SH, the cover has an opening OP substantially concentric to the circular outer contour, through which opening OP the rotor R extending along the longitudinal axis AX emerges from the housing CAS. The cover COV carries the shaft seal SSL and the radial bearing BE. The shaft seal SSL includes a labyrinth seal LS, a dry gas seal DGS, and a carbon ring seal KRS in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com