Copper bush press-in machine for connecting rod

A technology for press-fitting machines and copper sleeves, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of poor press-fit stability, low efficiency, and difficulty in meeting modern production, and achieve high production efficiency and improved work efficiency , Accurate and efficient docking press-in effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

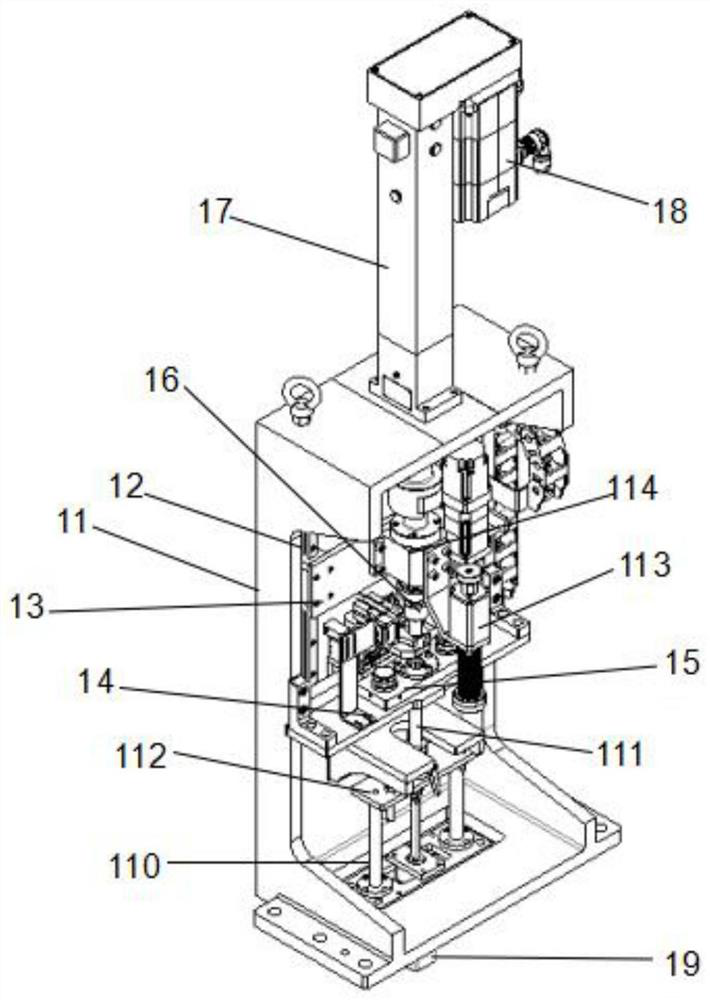

[0030] Embodiment: A connecting rod copper sleeve pressing machine.

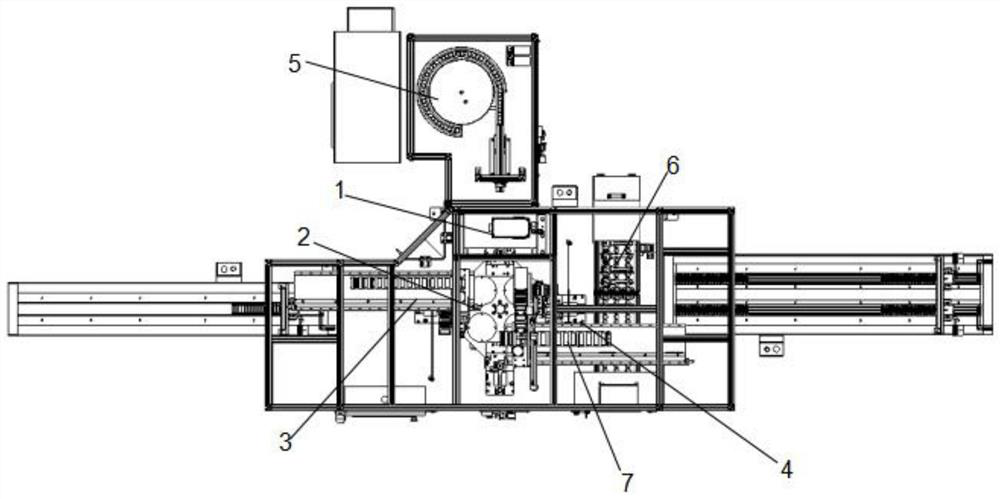

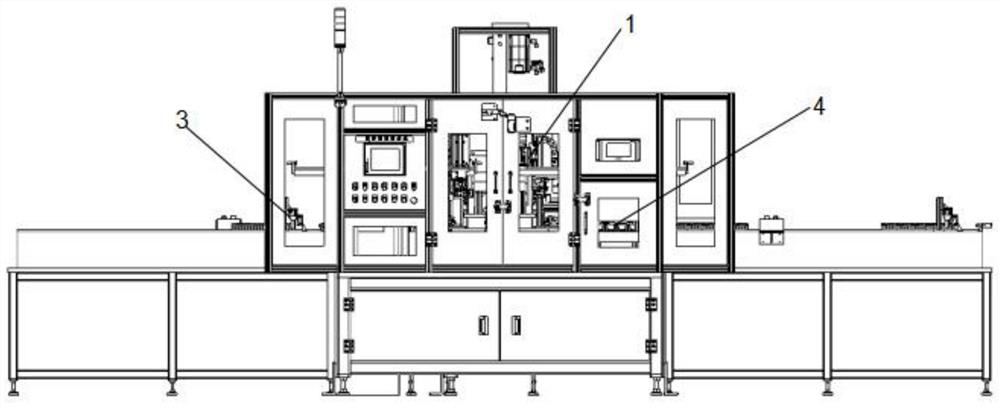

[0031] refer to Figure 1 to Figure 12 As shown, a connecting rod copper sleeve pressing machine includes:

[0032] Feeding and transferring mechanism 3, said feeding and transferring mechanism 3 comprises a feeding and transferring frame 31, said feeding and transferring frame 31 is provided with a feeding guide rail 32, and a feeding moving seat 33 is installed on said On the feeding guide rail 32, the feeding rack 35 that is arranged in parallel with the feeding guide rail 32 is also installed on the feeding material transfer frame 31, and the feeding driving motor 34 is vertically installed on the feeding mobile seat 33 downwards, so that Gears are installed on the output shaft of the above-mentioned feeding drive motor 34, and the gears are engaged with the feeding rack 35. The upper and lower driving cylinders 38 are fixed on the feeding moving seat 33 and are arranged vertically downward, and the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com