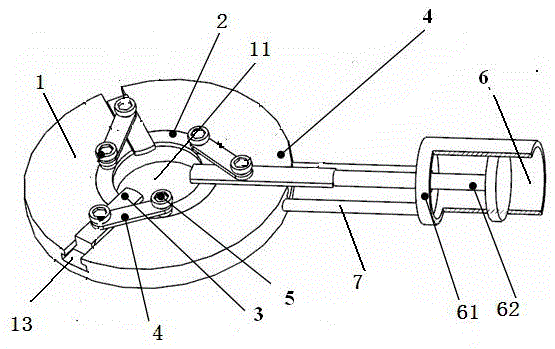

A three-jaw manipulator composed of three sets of crank-slider mechanisms

A crank-slider mechanism and manipulator technology, applied in manipulators, collets, manufacturing tools, etc., can solve problems such as unreliability, complicated production process, and affecting work efficiency, and achieve firm grasping of cylinders, simple manufacturing process, and easy grasping Take the effect of many objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

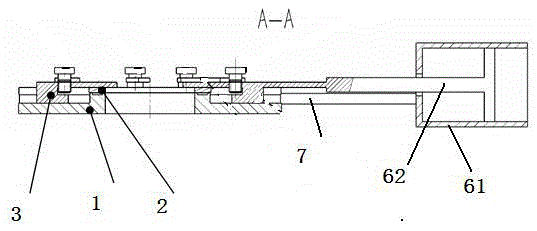

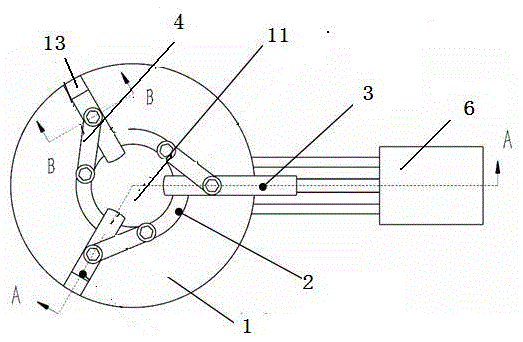

[0017] combine Figure 1 to Figure 7 , the present invention includes a master disk 1, a turntable 2, three finger sliders 3 located on the master disk 1, and three connecting rods 4 connected with the turntable 2 and the finger slider 3; the center of the master disk 1 is provided with a circular through hole 11 , the outer edge of the upper end of the circular through hole 11 is provided with an annular groove 12, the turntable 2 is located in the annular groove 12, and can rotate around the center of the master disk 1 along the annular groove 12; the upper end of the master disk 1 is also radially provided with three strips Shaped groove 13, the finger slider 3 is inserted in the bar-shaped groove 13 and is slidably connected with the bar-shaped groove 13, and can slide radially along the bar-shaped groove 13. One end of the connecting rod 4 is fixed on the turntable 2 by a hexagonal screw 5 , and the other end is firmly connected with the finger slider 3 .

[0018] Prefer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com