Cooking appliance

A technology for cooking utensils and containers, which is applied to the covers of cooking utensils, special materials for cooking utensils, cooking utensils, etc., can solve the problems that electric stew pots cannot continue to be used normally, users are easily scalded and rusted, and reduce heat dissipation. , food processing process is quiet, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

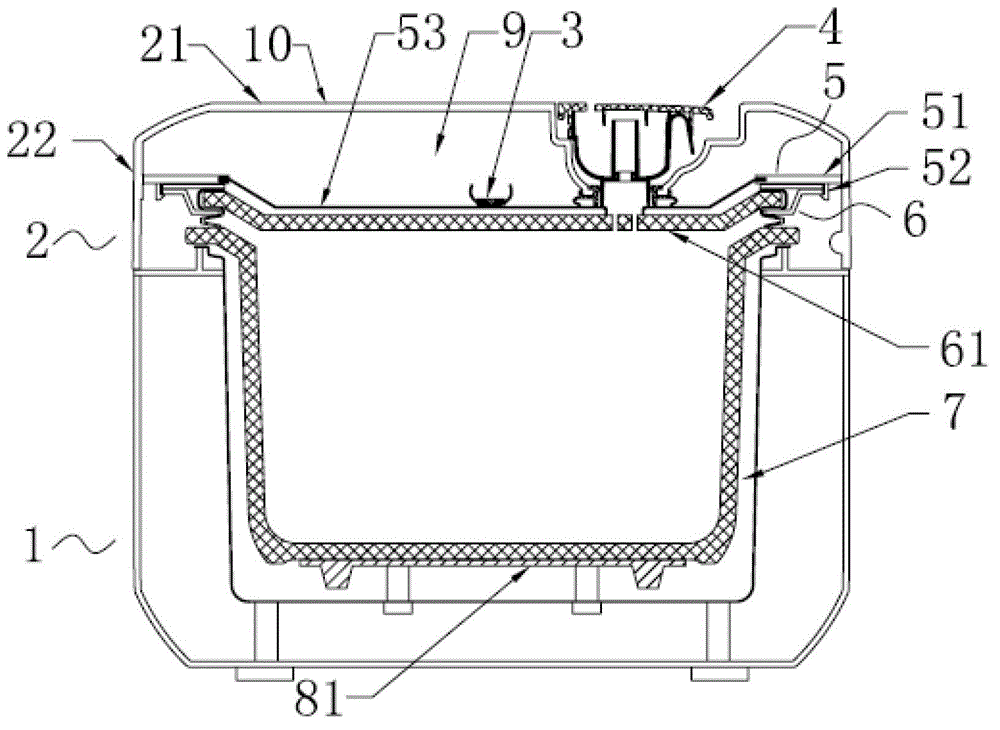

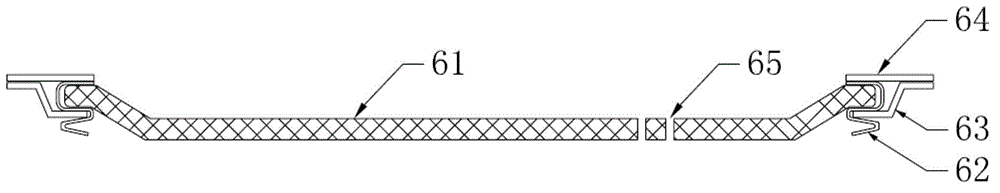

[0025] see Figure 1-Figure 3 The cooking utensil described in this embodiment includes a base body 1 and a cover body 2, a container 7 for holding food is arranged inside the base body 1, a first heating device 81 is arranged outside the container 7, and the cover body 2 It includes a plurality of cover layers, and gaps are reserved between adjacent cover layers. The cover layer of the cover body 1 on the side away from the container 7 is set as a top cover 21, and the cover layer on the side close to the container 7 includes an inner cover assembly 6. The inner cover assembly 6 includes an inner cover main body 61, the inner cover assembly 6 is sealed with the container 7, and the material of the container 7 and the inner cover main body 61 is ceramic or purple sand.

[0026] In this embodiment, the first heating device 81 is set at the bottom of the container 7, and the cover 2 is set on the base 1 through a rotating shaft and can be opened or closed by rotation. As a commo...

Embodiment 2

[0031] see Figure 4 The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the inner cover assembly 6 is flexibly connected to the side wall 22 of the cover body through the inner lining assembly 5, while in this embodiment, the inner cover assembly 6 is directly fixed to the cover body On the side wall 22, specifically, the cover body 1 of this embodiment includes a top cover 21, and the top cover 21 extends downward at the edge position to form the side wall 22 of the cover body, and the inner cover frame of the inner cover assembly 6 is fixed on The inner wall of the side wall 22 of the cover body is integrated with the cover body 1 , which can reduce the cost, and the second heating device 82 is arranged above the inner cover main body 6 .

Embodiment 3

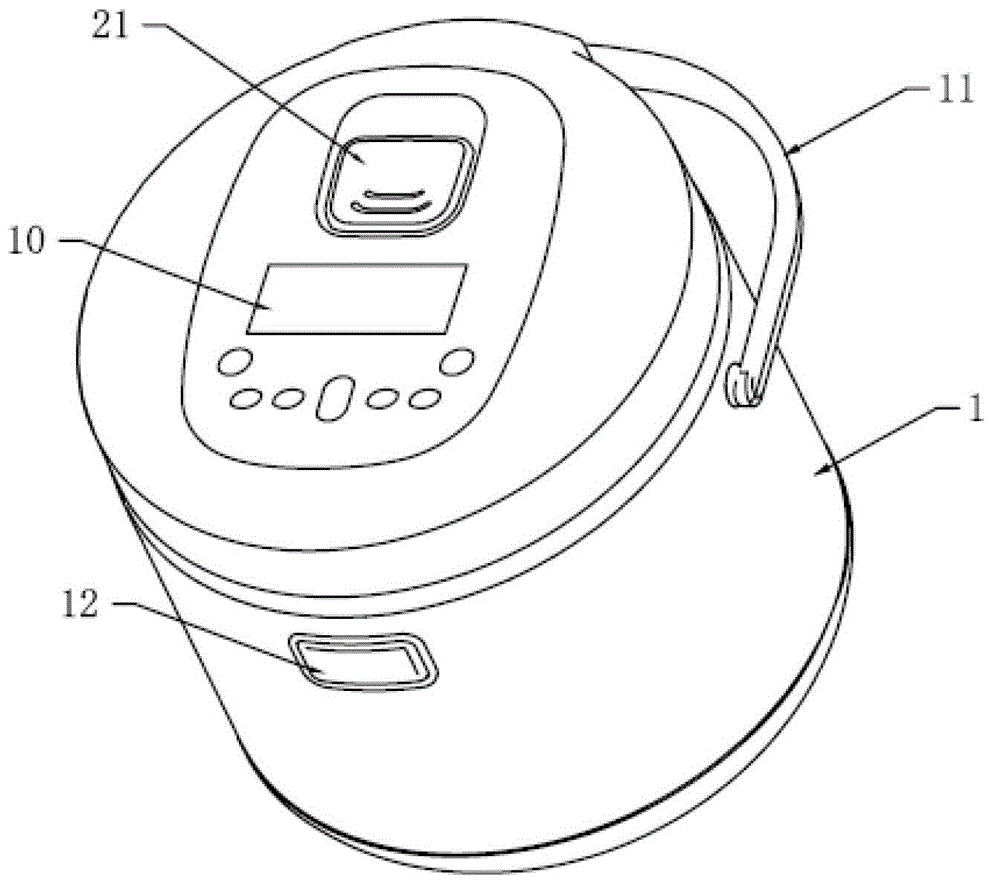

[0033] see Figure 5 The difference between this embodiment and Embodiment 1 is that the setting positions of the operation panel are different. Specifically, in this embodiment, the operation panel 10 is arranged on the front side of the base 1. Of course, the setting of the operation panel 10 in this embodiment The location can also be combined with the internal structure of the cooking appliance described in Embodiment 1 or Embodiment 2. Moreover, based on the diversified requirements of the operation, the operation panel 10 can also be arranged on the front side of the substrate or any other area that is convenient for operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com