Injection finishing control method of syringe injection pump

A control method and syringe technology, applied in the field of medical equipment, can solve problems such as failure to realize injection completion alarm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

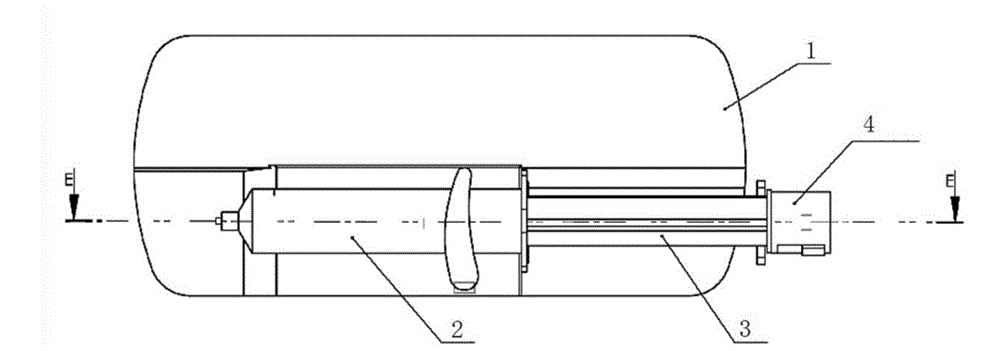

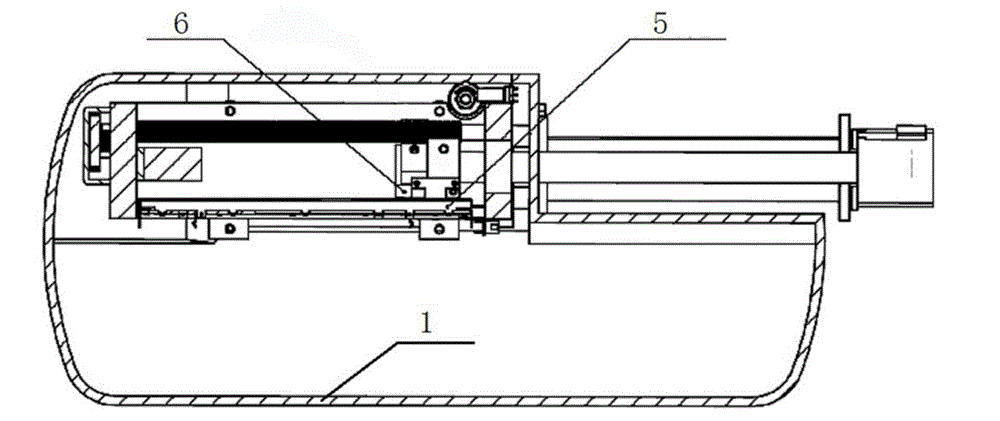

[0016] Such as figure 1 As shown, the syringe injection pump of this embodiment includes: a pump casing 1, a syringe 2 that is fixedly arranged inside the pump casing 1 and can temporarily store injection liquid (the cylinder wall of the syringe is engraved with a volume indicating capacity The scale line of the volume, which is engraved by the manufacturer during the manufacture of the syringe), slides the push rod 3 arranged in the syringe 2, and is used to drive the push rod 3 on the needle A propulsion mechanism 4 that slides in a straight line in the axial direction of the cylinder 1 to push out the injection liquid temporarily stored in the syringe.

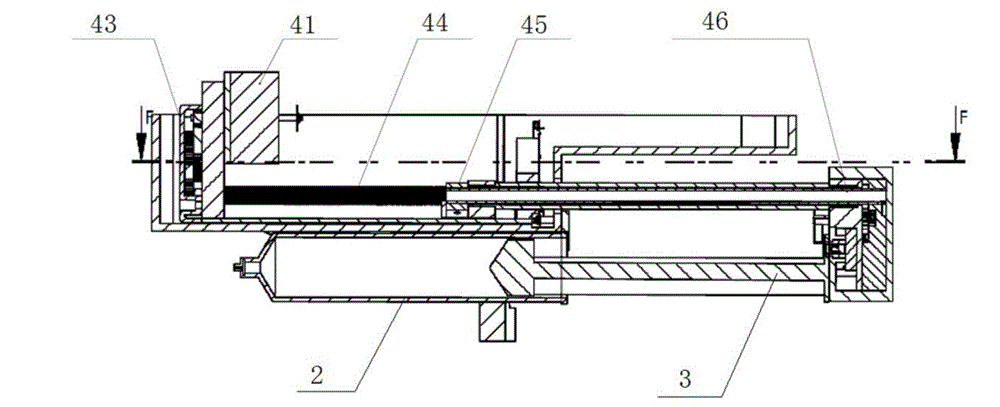

[0017] Such as figure 2 and image 3 As shown, the propulsion mechanism 4 includes a stepping motor 41 that provides power, a computer control system (not shown in the figure) that controls the operation of the stepping motor 41, a screw 44 arranged in parallel with the push rod 3, and A power rod 46 arranged parallel t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com