Spiral thin film element and its preparation method

A thin-film element, spiral technology, applied in the field of spiral thin-film element and its preparation, can solve the problems of fluid dead angle, easily damaged membrane cementation parts, reduce the effective filtration area of the membrane, etc., and achieve the effect of maintaining integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

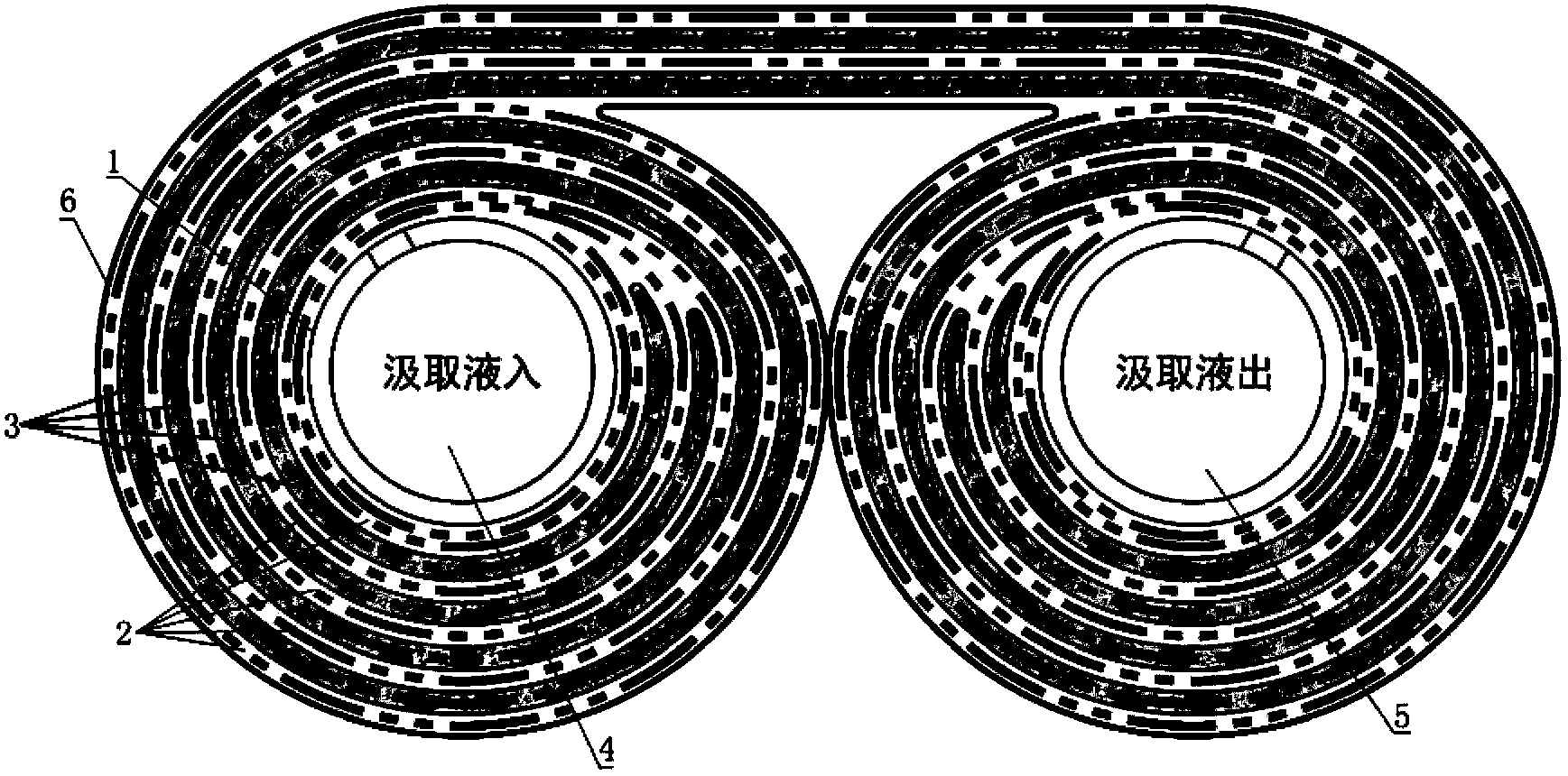

[0049] Preferably, as an implementable manner, see image 3 , the spiral membrane element takes the drawing liquid inlet connecting pipe 4 and the drawing liquid outlet connecting pipe 5 as the axis respectively, and the film layer composed of the forward osmosis membrane 1, the drawing liquid guiding material 2 and the feeding liquid guiding material 3 is closely attached to The drawing liquid inlet connecting pipe 4 and the drawing liquid outlet connecting pipe 5 are spirally wound into a first cylindrical winding body and a second cylindrical winding body. In this embodiment, two wound bodies are formed, so that the flux of the spiral membrane element is large, and it is suitable for higher pressure.

[0050] Preferably, as an implementation mode, the sealing part in this embodiment includes an outer sealing part 6 and an inner sealing part, and the outer sealing part is arranged on the first cylindrical winding body and the second cylindrical winding body. The two axial e...

Embodiment 2

[0057] This embodiment is another implementation of the spiral thin film element. Preferably, as an implementable manner, see Figure 4 , the spiral membrane element takes the drawing liquid inlet connection pipe 4 as the axis, and the film layer composed of the forward osmosis membrane 1, the drawing liquid diversion material 2 and the feed liquid diversion material 3 is closely attached to the suction liquid inlet connection pipe 4 spirally wound into a third cylindrical winding body, and the end of the film layer is embedded in the drawing liquid outlet connector 5 . In this embodiment, only one cylindrical wound body is formed, and no wound body is formed on the outside of the drawing liquid outlet connecting pipe, so that the formed spiral membrane element is small in size and easy to install.

[0058] Preferably, as an implementable manner, see Figure 4 , the sealing part in this embodiment includes an outer sealing part 6 and an inner sealing part, and the outer seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com