Mechanically clamped turning tool for ring slot with stepped end surface

A technology of end faces and machine clamps, which is applied to the lathe tools, turning equipment, tool holder accessories, etc., can solve the problems that affect the production progress of the product, the difficulty of the tool head, and the serious breaking of the tool, so as to reduce the broken tool and improve the quality of the tool. The strength of the blade and the effect of speeding up the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

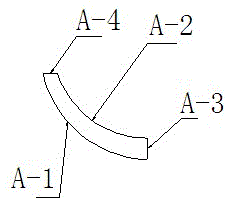

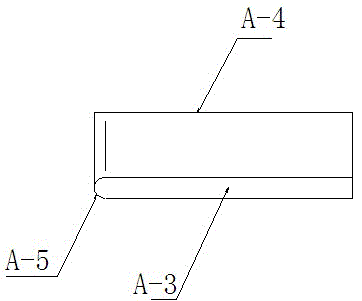

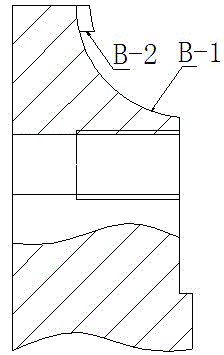

[0018] Such as figure 1 , 2 , As shown in 3 and 4, a step end face ring groove machine clamping tool includes a cutter head 1 and a cutter body 2, and the cutter head and cutter body are split structures. The cutter head is sickle-shaped, and the cutter head includes the inner arc surface A-1 of the cutter head, the outer arc surface A-2 of the cutter head, the rake face A-3, the bottom surface A-4 and the arc surface A-5 of the cutter head, Among them, the inner arc surface of the cutter head, the outer arc surface of the cutter head, the rake face and the bottom surface are all processed by wire cutting. The arc surface of the cutter head is manually ground and measured by the grinding sample; Interference occurs with the arc surface of the workpiece to be processed, and the width of the cutter head gradually narrows from the rake face to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com