Processing device for sliding sleeve of low-power motor

A processing device and motor technology, applied in the direction of the chuck, etc., can solve the problems of poor consistency of the inner circle dimensional accuracy of the sliding sleeve bearing, low part qualification rate, etc., to meet production requirements, ensure the parts qualification rate, and improve the inner circle dimensional accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

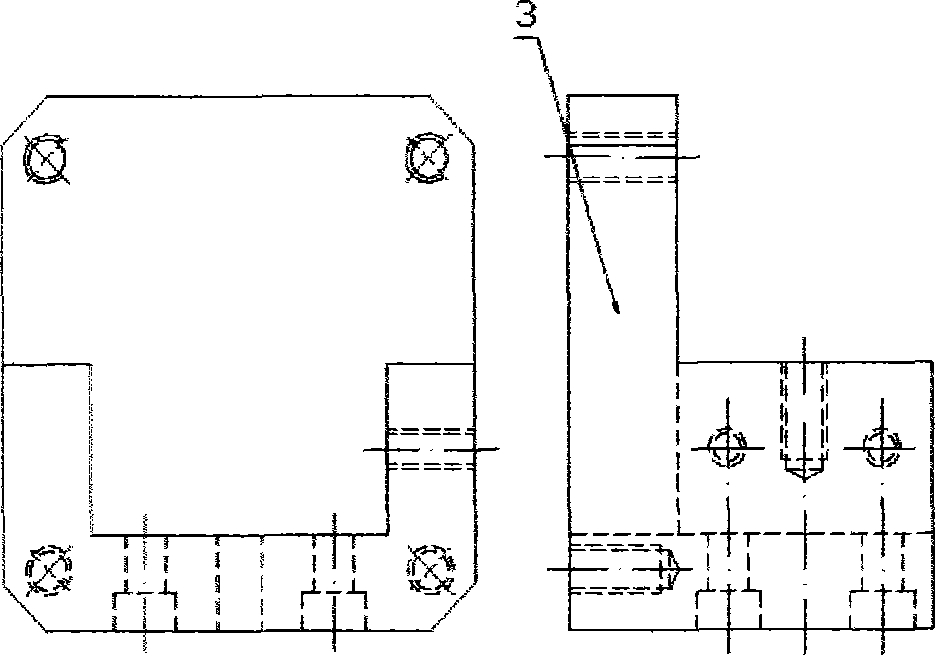

[0024] like image 3 As shown, the axial length of the mounting block of the lower positioning bracket 3 along the horizontal direction is not greater than one-sixth of the total axial length of the lower positioning bracket 2 . It can not only meet its fastening effect, but also ensure the use of the device.

Embodiment 2

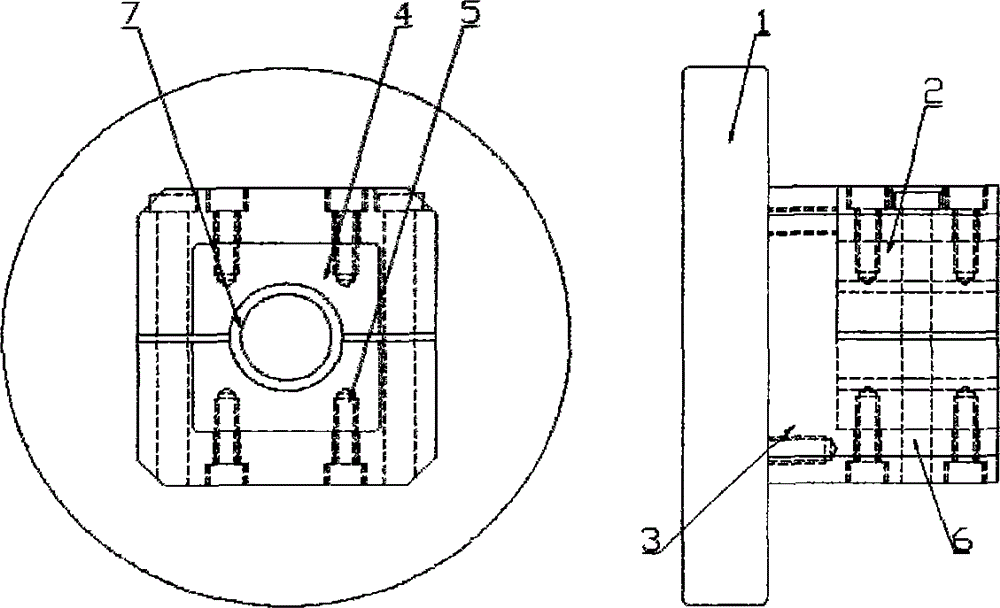

[0026] like figure 1 As shown, the axis of the mounting disc seat 1 according to the present invention coincides with the axis of the sliding sleeve 7 . The precision of the processed product parts can be guaranteed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com