Pull pin type diamond rope saw and manufacturing method

A diamond wire saw and the technology of its manufacturing method are applied in the direction of metal sawing equipment, sawing machine tool manufacturing, tool manufacturing, etc., and can solve the problems of large size and power requirements, large slits, and high quality of the matching wire saw cutting machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

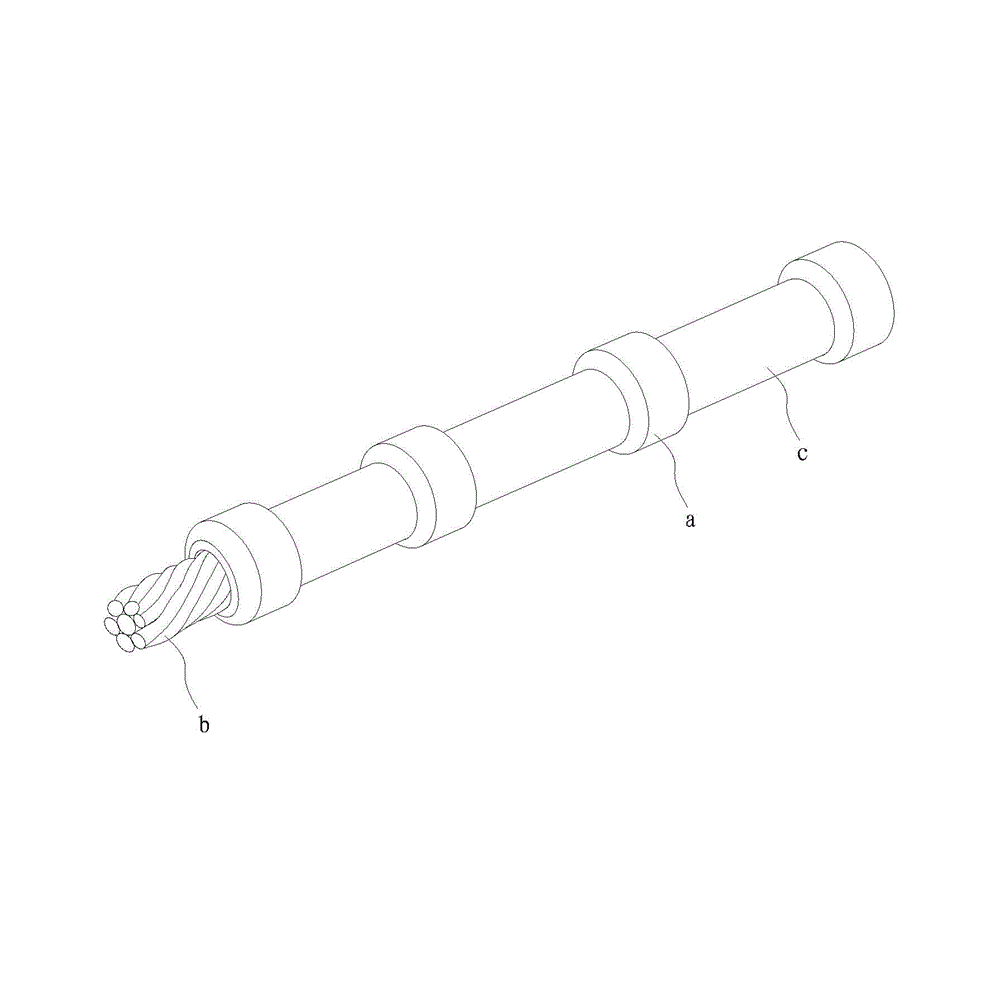

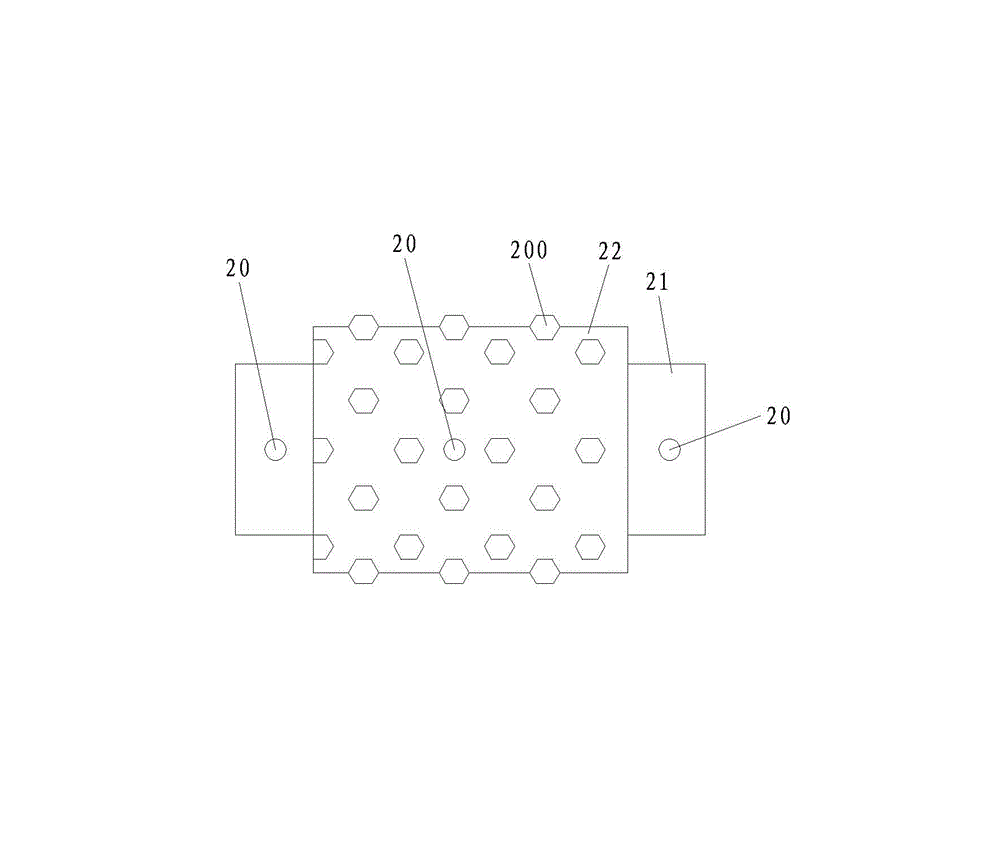

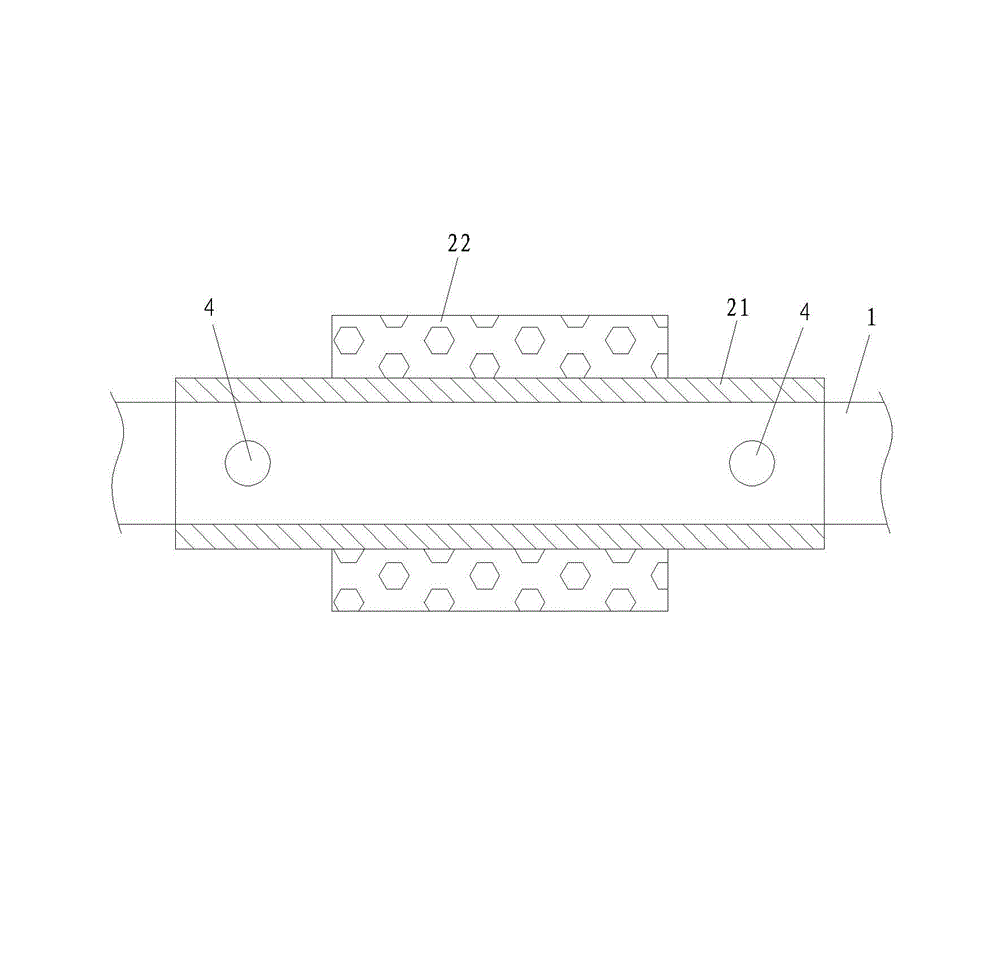

[0032] Example: see Figure 2 to Figure 9 , a pin-pull diamond wire saw, comprising a steel wire rope 1 and several diamond beads 2 sheathed thereon, each bead is formed by sintering a base tube 21 and a diamond working layer 22, and the base tube 21 has at least radially arranged A group of holes 20 pull pins 4 pass through the steel wire rope 1 in the above-mentioned base tube and the holes on both sides, and each bead is strung into the steel wire rope and injected to form an anti-rotation diamond wire saw with a diameter of Φ3-Φ5.5mm, wherein the injection molding material is formed to form a spacer layer 5 and pour into the beads along the direction of the steel wire rope and fill them around the pull pin 4 to block the diamond beads 2 to avoid the relative rotation of the beads and the steel wire rope 1 during cutting. The two sides of the diamond working layer 22 are provided with recesses or grooves, and the base tube 21 is provided with holes corresponding to the abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com