Gluing and glue adjusting mechanism of single face corrugated board machine

A corrugated cardboard machine, single-sided technology, applied to the surface coating liquid device, machining/deformation, coating, etc., can solve the problems of complex mechanism and high cost, improve product quality, easy operation, and cost saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific drawings and embodiments.

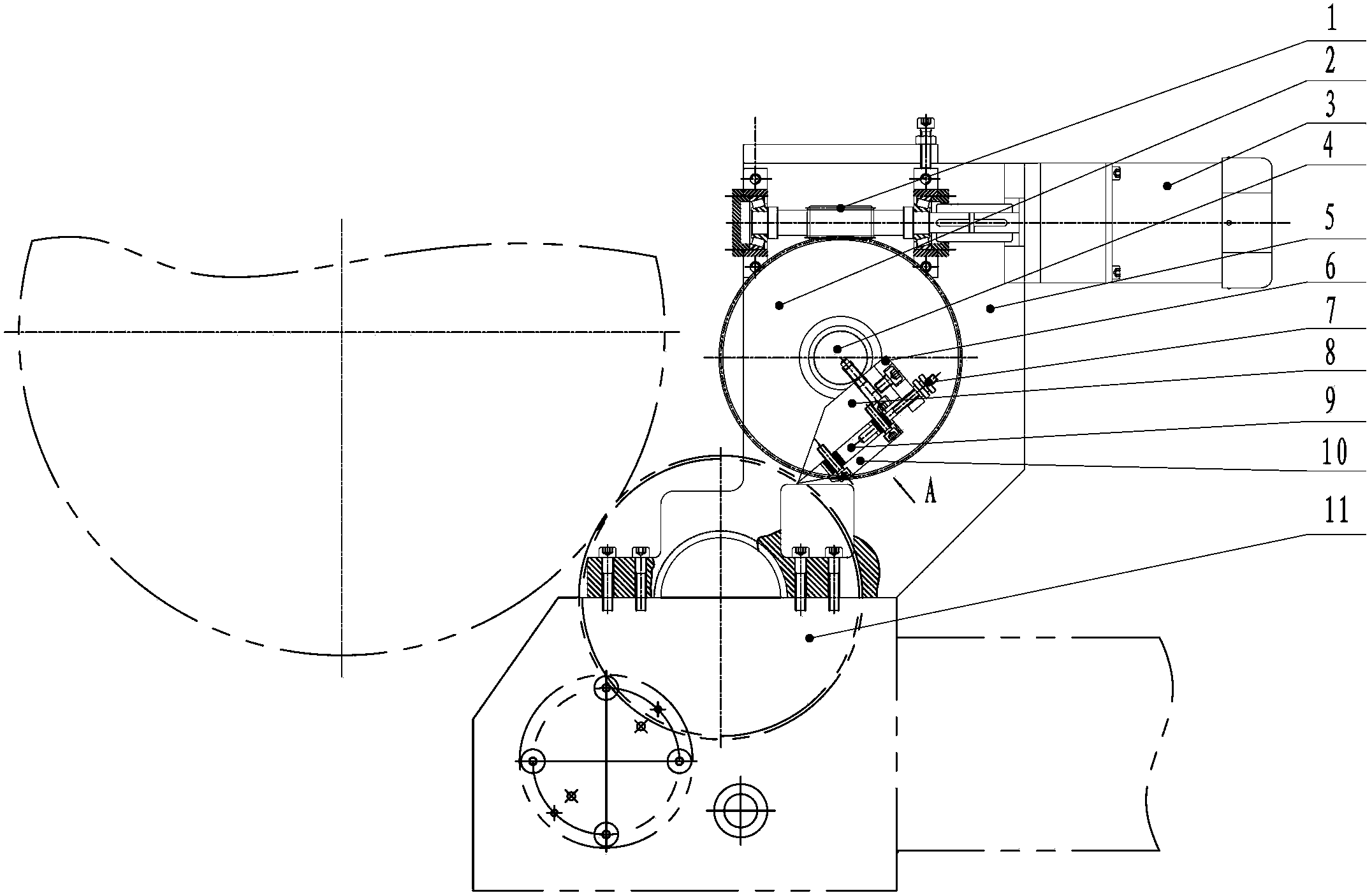

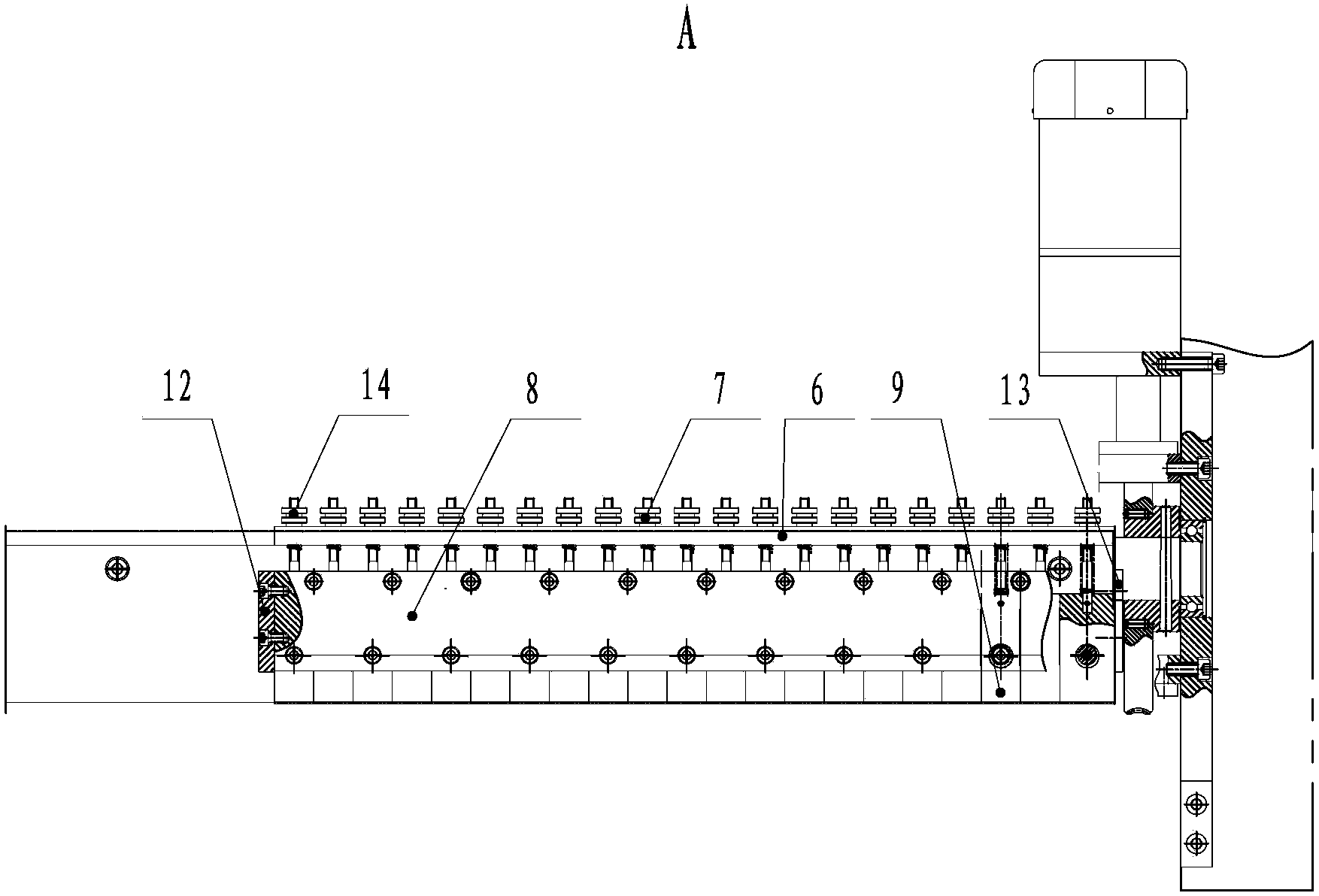

[0011] Such as figure 1 , figure 2 As shown, it includes worm 1, turbine 2, motor 3, rotating shaft 4, fixed plate 5, adjusting fixed plate 6, adjusting screw 7, main scraper 8, floating knife 9, pressure plate 10, rubber roller 11, first side stop of floating knife Plate 12, floating knife second side baffle plate 13, nut 14, etc.

[0012] Such as figure 1 , figure 2 As shown, the gluing and gluing mechanism of the single-face corrugated cardboard machine of the present invention is provided with a fixed plate 5 and a rubber roller 11 on the rubber roller seat, and a motor 3 is installed on the fixed plate 5, and the output end of the motor 3 is connected to the worm 1 A rotating shaft 4 is arranged below the worm 1, and a turbine 2 matching with the worm 1 is installed on the rotating shaft 4. The rotating shaft 4 is fixedly connected to the main scrape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com