Carton sealing machine with carton pressing mechanism

A sealing machine and crimping technology, which is applied in the directions of packaging sealing/fastening, external support, transportation packaging, etc., can solve the problems of troublesome operation and low work efficiency, and achieve the advantages of convenient operation, large height adjustment range and convenient installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

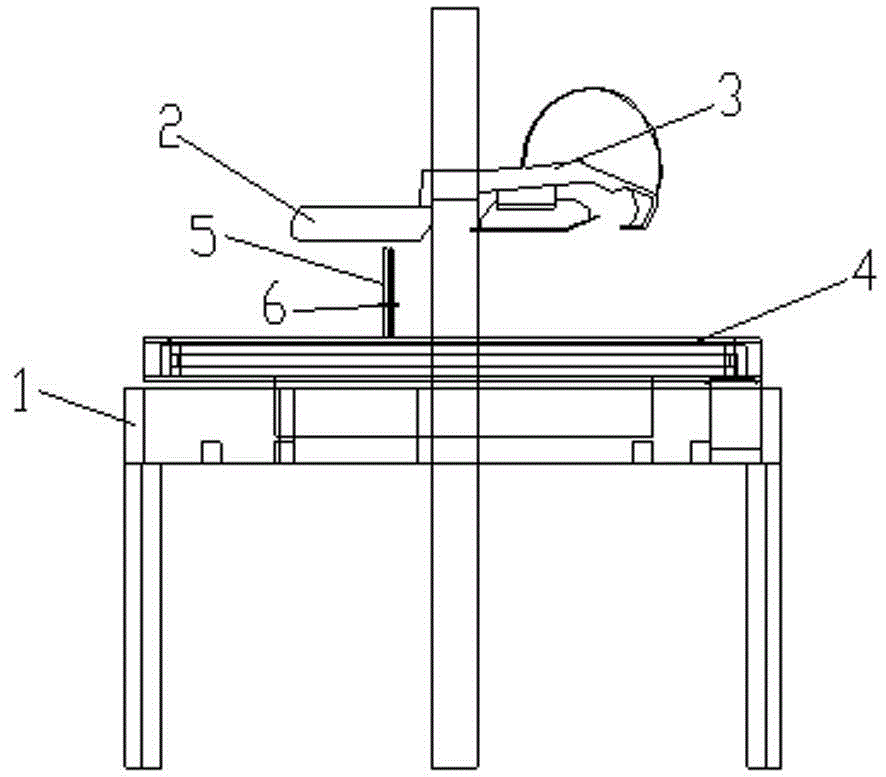

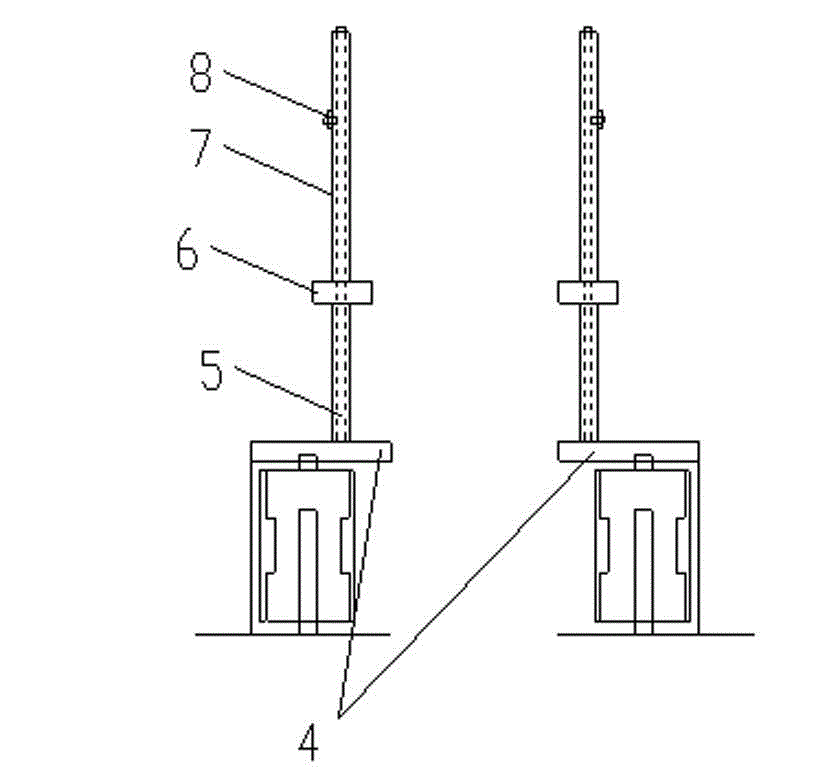

[0018] Refer to attached figure 1 As shown, a case sealing machine with a crimping mechanism is used for sealing cartons, including a machine base 1, and a device for sealing the carton upper cover arranged above the machine base 1 The upper core 2, the cover folding mechanism 2 for folding the carton top cover arranged at the front of the machine base 1, and two conveying devices 4 for forming the carton conveying channel, the conveying devices 4 are slidably arranged on the On the base 1, the sliding direction of the conveying device 4 is perpendicular to the conveying direction of the carton, and the sealing machine also includes columns 5 respectively fixedly arranged on the two conveying devices 4 for compressing the cartons. The side pressure wheel 6 on the top of the side plate of the carton is slidably arranged on the column 5 .

[0019] After the distance adjustment between the two conveying devices 4 is completed, the width between the two side pressure wheels ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com