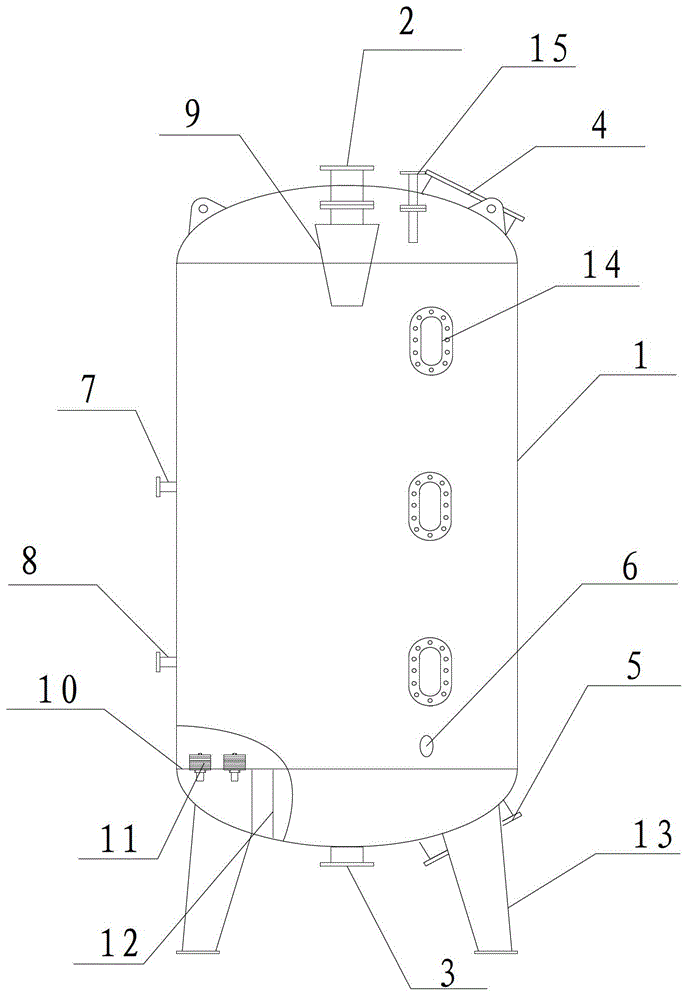

Mixed bed structure of water treatment system

A water treatment system and mixed bed technology, applied in the field of water treatment, can solve problems such as poor precision and safety, slow resistance washing speed, troublesome installation, replacement and disassembly, etc., achieve high precision and safety, improve regeneration effect, Ease of installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

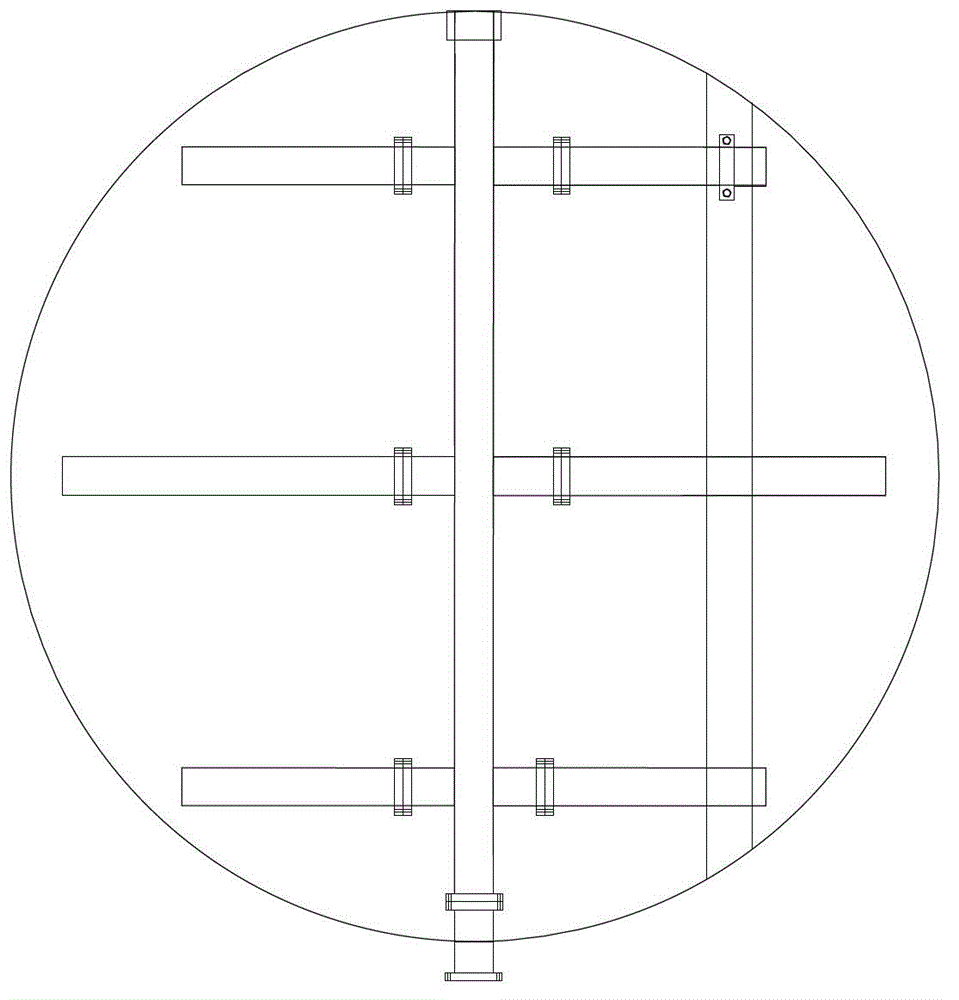

[0022] The traditional mixed bed is generally equipped with a water distribution device at its water inlet, which is an orifice plate with a water cap. Through the function of the water cap, the ionized water will fall evenly through the anion exchange resin and cation exchange resin in turn, and then be discharged through the water outlet. Enter the next processing procedure. The water cap is installed on the orifice plate, which is easy to fall off and deform, which affects the water distribution effect, and the installation, replacement and disassembly are more troublesome, and the precision and safety are poor. The regeneration effect of the yin bed and the yang bed is not ideal, and the resistance washing speed is slow and the cycle is short.

[0023] The present invention aims at the deficiencies in the prior art, and the present invention provides a mixed bed structure of a water treatment system to achieve a mixed bed that effectively solves the water distribution prob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com