Nylon modified material and preparation method thereof

A modified material, nylon technology, applied in the field of nylon modified materials and its preparation, can solve the problems of polymer material performance enhancement, no significant enhancement of nylon material mechanical properties, and increased preparation process complexity, etc., to achieve enhanced toughness and resistance Impact resistance, prevention of crystal nucleation, and improvement of interface conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

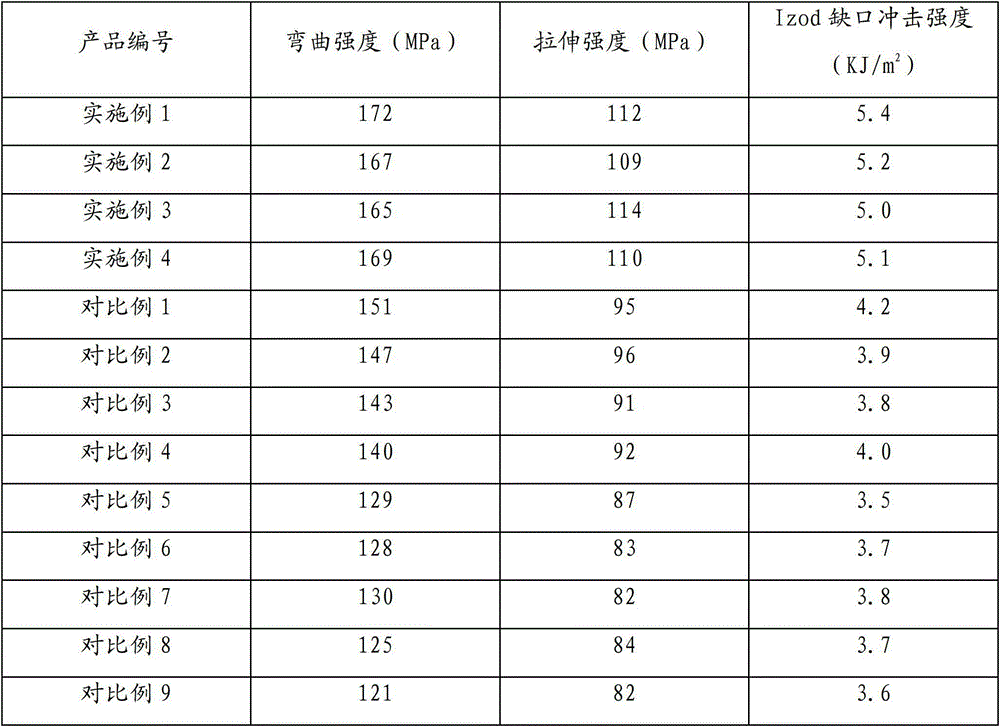

Examples

Embodiment 1

[0028] 63 parts of nylon, 10 parts of nanomaterial dispersion modifier ethylene-propylene copolymer, 10 parts of styrene butyl acrylate binary graft modified ethylene-propylene rubber, 12 parts of nano attapulgite, and 5 parts of nano-apatite whiskers , 0.1 part of antioxidant BHT, and 5 parts of processing aid stearic acid, added to a high-speed mixing mixer, stirred and mixed until uniform; melted, kneaded, extruded, cooled, dried, cut through a twin-screw extruder grain.

Embodiment 2

[0030] Using the preparation process of Example 1, the parts by weight of each component are: 69 parts of nylon, 10 parts of nanomaterial dispersion modifier alpha olefin oligomer, 8 parts of styrene butyl acrylate binary graft-modified ethylene propylene rubber parts, 12 parts of nano-attapulgite, 4 parts of nano-apatite whiskers, 10,102 parts of antioxidant, and 0.1 part of processing aid white mineral oil.

Embodiment 3

[0032]Using the preparation process of Example 1, the parts by weight of each component are: 73 parts of nylon, 7 parts of nanomaterial dispersion modifier ethylene-propylene copolymer, 6 parts of styrene butyl acrylate binary graft modified ethylene-propylene rubber , 8 parts of nano-attapulgite, 2 parts of nano-apatite whiskers, 1680.1 parts of antioxidant, 5 parts of processing aid silicone oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com